Big Bore

New member

So I was doing math this morning figuring the flow of 300cc injectors at 3500rpm.

Injector flow as far as I know is based on 1000 shots.

So 300x8 is 2400cc, but since its a 4 stroke motor, at 1000rpm flow is half that at 1200cc.

At 3500rpm it would be 1200cc x 3.5 = 4200cc per minute.

4200cc per minute is 1.1gpm.

1.1gpm is 66gph.

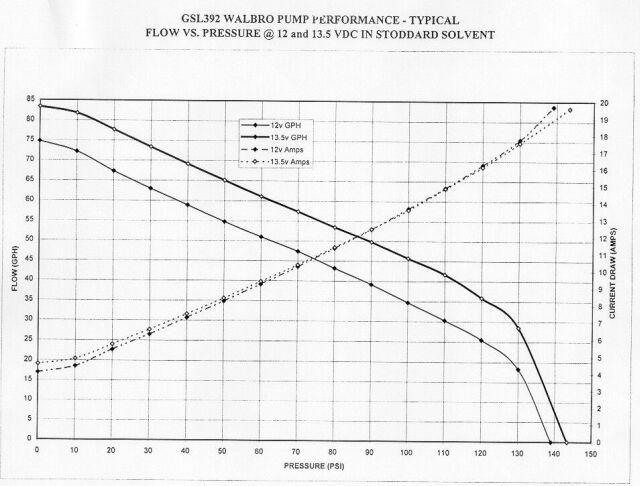

My Walbro, according to this graph, at 62psi is around 50gph.

Looks like I need to do the dual SD pump setup.

Anyone know the flow specs on a stock pump?

Injector flow as far as I know is based on 1000 shots.

So 300x8 is 2400cc, but since its a 4 stroke motor, at 1000rpm flow is half that at 1200cc.

At 3500rpm it would be 1200cc x 3.5 = 4200cc per minute.

4200cc per minute is 1.1gpm.

1.1gpm is 66gph.

My Walbro, according to this graph, at 62psi is around 50gph.

Looks like I need to do the dual SD pump setup.

Anyone know the flow specs on a stock pump?