genie144

Member

So have been having some fuel pressure issues and some issues with my switching valves. I believed the root cause of the issues were related to the routing of the fuel system which was not ideal and the sticking selector valve. This is a work in progress but should be wrapped up by the weekend and fix my issues (fingers crossed):

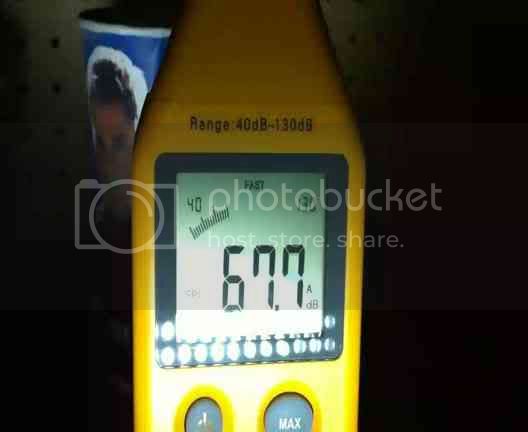

Fuel Pump - Key on Engine Off - dB meter ~10' away at ~5' elevation

Same as above:

db Meter under truck - KOEO

Same:

Rail Mount:

Pre-Dahls Tee:

Pre-Dahl Tee 2nd angle:

Outlet from Selector Valve:

180 Selector Valve Outlet:

Unions:

Dahl 1 outlet:

Return Selector Valve:

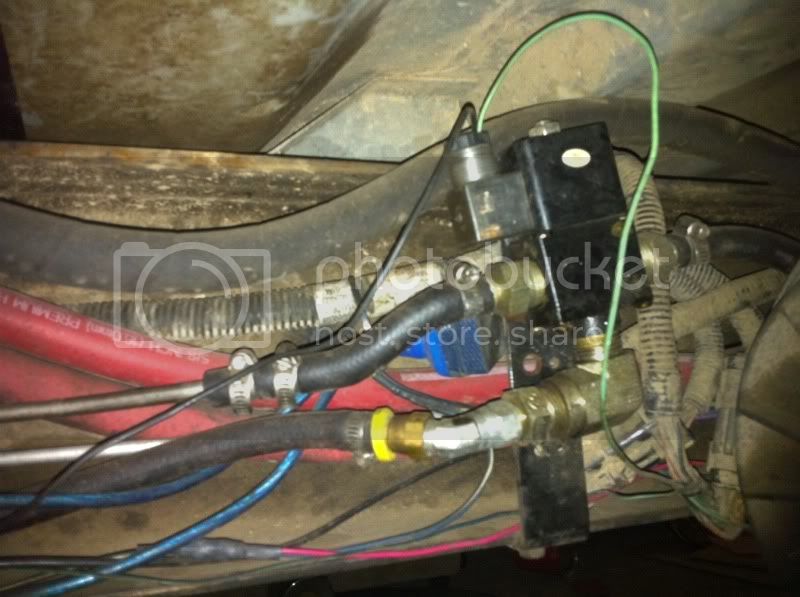

Wiring Mess:

So that was what I was starting with. The routing was necessitated by some last minute changes and obviously is not ideal for a stock setup let alone a high performance SVO fuel system.

This is where I am at now:

Factory Tank:

Frame Rail:

Coolant Filter (this is causing a problem):

Rerouted Wiring:

So now that the system is gutted - it is time to rebuild it and make it all fit... Quite the challenge...

Back of Mounting Box:

Money Shot:

Bed towards Engine:

Engine towads Bed:

So that is where I am at. The bracket is fabbed and the mounting tabs for the filters are welded into place. I am needing a few specialty connections to actually get everything mounted. Once I have the filters mounted in place, I will be working on locating the tank selector valves to minimize bends, loops, etc in the fuel line. Once everything everything is welded (tabs for selector valves) I will be putting some sound deadener on the inside of the box. Then the whole thing will be painted with some rubberized undercoating I have from previous sound proofing projects. I am not sure how long the coating will last - eventually I will have it recoated with truck bed liner.

The goal is to improve the pump performance (fuel pressure) and decrease the volume of the pump inside and outside of the truck. 90dB is a bit obnoxious for a pump at 10 feet and 5 feet up.

Sam

Fuel Pump - Key on Engine Off - dB meter ~10' away at ~5' elevation

Same as above:

db Meter under truck - KOEO

Same:

Rail Mount:

Pre-Dahls Tee:

Pre-Dahl Tee 2nd angle:

Outlet from Selector Valve:

180 Selector Valve Outlet:

Unions:

Dahl 1 outlet:

Return Selector Valve:

Wiring Mess:

So that was what I was starting with. The routing was necessitated by some last minute changes and obviously is not ideal for a stock setup let alone a high performance SVO fuel system.

This is where I am at now:

Factory Tank:

Frame Rail:

Coolant Filter (this is causing a problem):

Rerouted Wiring:

So now that the system is gutted - it is time to rebuild it and make it all fit... Quite the challenge...

Back of Mounting Box:

Money Shot:

Bed towards Engine:

Engine towads Bed:

So that is where I am at. The bracket is fabbed and the mounting tabs for the filters are welded into place. I am needing a few specialty connections to actually get everything mounted. Once I have the filters mounted in place, I will be working on locating the tank selector valves to minimize bends, loops, etc in the fuel line. Once everything everything is welded (tabs for selector valves) I will be putting some sound deadener on the inside of the box. Then the whole thing will be painted with some rubberized undercoating I have from previous sound proofing projects. I am not sure how long the coating will last - eventually I will have it recoated with truck bed liner.

The goal is to improve the pump performance (fuel pressure) and decrease the volume of the pump inside and outside of the truck. 90dB is a bit obnoxious for a pump at 10 feet and 5 feet up.

Sam