So on fuel only, how many crank degrees do you think we have to EFFECTIVELY inject the fuel and make power? This thread is a technical discussion and anyone with non-technical comments like "my brand x injectors make power at 4000 rpms" will be deleted at my request. The data flushed out of this thread will play into the next thread discussing nitrous and why it makes more power.

I am not talking about hitting the bowl or not hitting the bowl either..... Taking that out of the equation completely - how late do you think we can inject the fuel and still convert that into power vs just smoke and heat? You have decreasing cylinder pressure fighting the increase in cylinder volume on the power stroke.

From my observations:

30 degrees ATDC - good to go with slight smoke

40 degrees ATDC - diminishing returns with heavy smoke

50 degrees ATDC - looking like a dodge with a smarty

Anybody want to refute these numbers?

There is 18 degrees per millisecond eclipsed at 3000 RPMs.

There is 24 degrees per millisecond eclipsed at 4000 RPMs.

Injector delay= somewhere between .6 and .7ms on typical injectors at 3000 PSI.

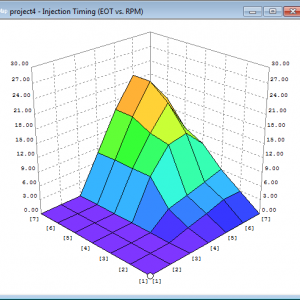

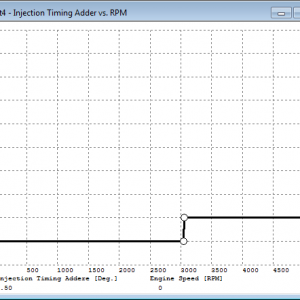

So lets say we have an actual injection timing (not electrical) at 3000 rpms of 10 degrees. That would give 40 degrees of crank rotation to "do the deed" and make power. Pulsewidth commanded in that case would be 40/18 or 2.2ms (window) + .7ms (delay) so around 3ms of PW.

The same thing at 4000 is similar but i will throw in 5 degrees of timing extra so we will have 45 degrees of "window" at that point so 45/24 = 1.88 with the timing delay of .7 making 2.58ms total commanded the place to be for optimal injection there.

This make sense to everyone?

I am not talking about hitting the bowl or not hitting the bowl either..... Taking that out of the equation completely - how late do you think we can inject the fuel and still convert that into power vs just smoke and heat? You have decreasing cylinder pressure fighting the increase in cylinder volume on the power stroke.

From my observations:

30 degrees ATDC - good to go with slight smoke

40 degrees ATDC - diminishing returns with heavy smoke

50 degrees ATDC - looking like a dodge with a smarty

Anybody want to refute these numbers?

There is 18 degrees per millisecond eclipsed at 3000 RPMs.

There is 24 degrees per millisecond eclipsed at 4000 RPMs.

Injector delay= somewhere between .6 and .7ms on typical injectors at 3000 PSI.

So lets say we have an actual injection timing (not electrical) at 3000 rpms of 10 degrees. That would give 40 degrees of crank rotation to "do the deed" and make power. Pulsewidth commanded in that case would be 40/18 or 2.2ms (window) + .7ms (delay) so around 3ms of PW.

The same thing at 4000 is similar but i will throw in 5 degrees of timing extra so we will have 45 degrees of "window" at that point so 45/24 = 1.88 with the timing delay of .7 making 2.58ms total commanded the place to be for optimal injection there.

This make sense to everyone?

Last edited: