- Joined

- May 22, 2011

- Messages

- 15,240

- Reaction score

- 1

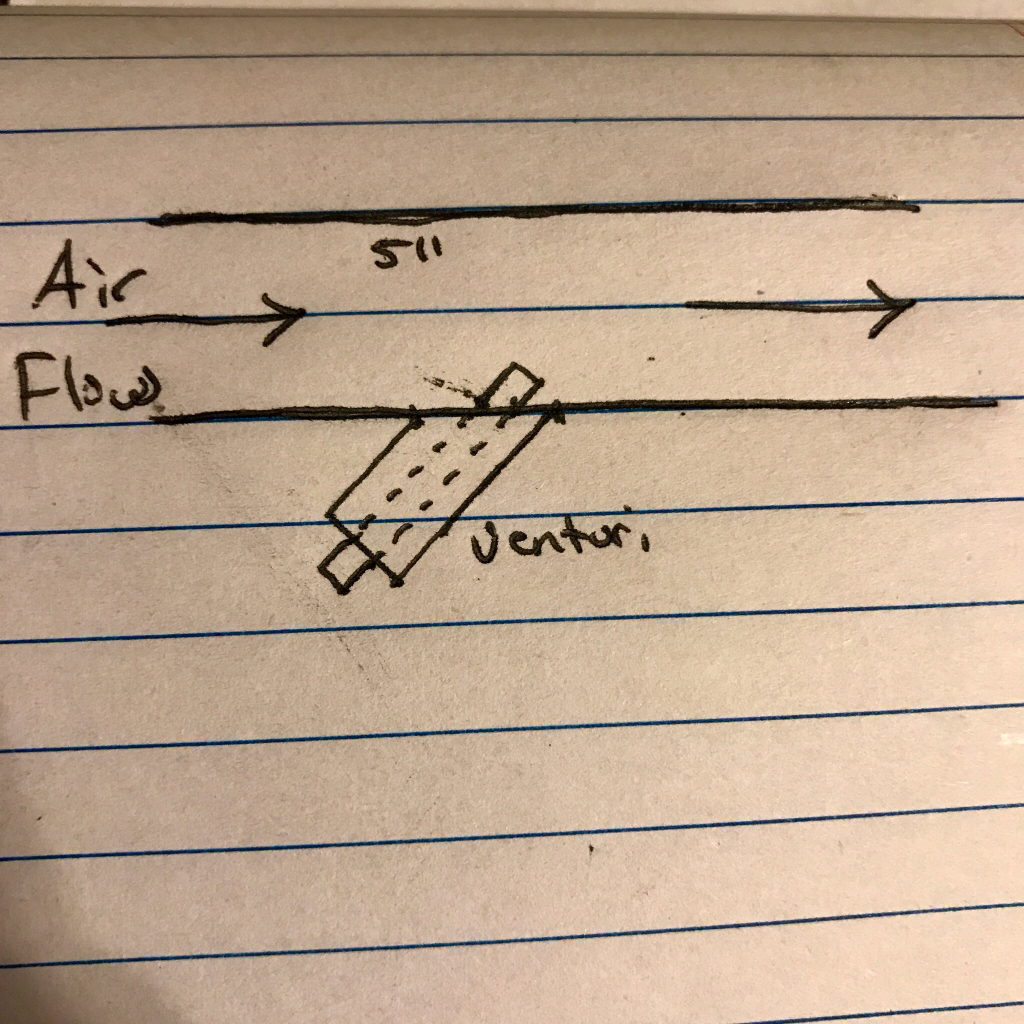

Hmm maybe I'll put a bag on mine and see if it does the same thing. Can always just vent it under the truck again and cap off the Venturi

Sent from my iPhone using Tapatalk

you would have a huge problem if you've been running it and it hasn't been working ie: blowing back, you're fine.