JoeDaddy

New member

I should be the last person to do a DIY because of the way I do most chops.

That said I've been doing them since I was a teenager stretching 2 ton frames and building trailers. I spent several years building off road race chassis, and in the last 10 years street trucks. Both stretches and chops.

So here's where I started this one, which is my 1st SD chop.

A grossly over-long 2000 SD 2WD.

Pulling the bed is obligatory, no reason to cover that or reinstall.

Start by disconnecting the E-brake and cutting the flange off. I used a 10" Milwaukee blade.

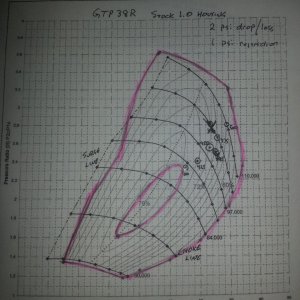

Then mark out your diagram. I'm using a 5" horizontal in a lazy Z notch cut. The cut is 16 and an 1/8" so we need 21 and 1/8" of straight space. I place the bottom cut toward the rear to lesson the chance of a stress fracture. I only use a sawzall to cut frames. IMO the less you overheat the frame the more strength is retained.

Measure 10 times then once more before you cut. LOL

The next step is the most critical in my opinion. This where the chop will succeed or fail. Grind the area's to be welded to a knife edge. Take time to do this right and not grind to deep.

That said I've been doing them since I was a teenager stretching 2 ton frames and building trailers. I spent several years building off road race chassis, and in the last 10 years street trucks. Both stretches and chops.

So here's where I started this one, which is my 1st SD chop.

A grossly over-long 2000 SD 2WD.

Pulling the bed is obligatory, no reason to cover that or reinstall.

Start by disconnecting the E-brake and cutting the flange off. I used a 10" Milwaukee blade.

Then mark out your diagram. I'm using a 5" horizontal in a lazy Z notch cut. The cut is 16 and an 1/8" so we need 21 and 1/8" of straight space. I place the bottom cut toward the rear to lesson the chance of a stress fracture. I only use a sawzall to cut frames. IMO the less you overheat the frame the more strength is retained.

Measure 10 times then once more before you cut. LOL

The next step is the most critical in my opinion. This where the chop will succeed or fail. Grind the area's to be welded to a knife edge. Take time to do this right and not grind to deep.