rusty1161

Member

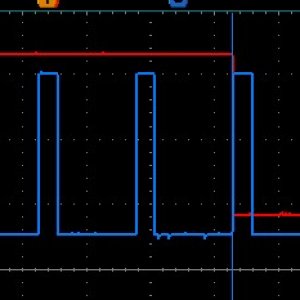

I did the Irate T4 conversion on my truck and initially had barely adequate clearance at the cooler line. Over time, the cooler line was rubbing the downpipe. Here is my solution while adding 3/8" SD hardlines.

1 - Edelmann #822560 5/16" flare to 3/8" tube elbow. $11 at Amazon

The rest of the parts I had from trying to add the SD 3/8" lines and bypass. The front cooler connection is worse with the SD 3/8" bypass/hardline setup. You do need the rear fitting from the bypass to connect the rear hardline. You also need the aluminum spacers https://www.strictlydiesel.com/p-2726-4r100-cooler-bypass-******-kit.aspx from Strictly Diesel or another vendor to eliminate the bypass. Clear as mud?

Here is the Edelmann fitting

Here is the fitting installed by itself

A closeup showing the clearance. I may adding an insulating cover for the hose

Here is how I connected to the cutdown hardline

Here is clearance at it's best with the original 5/16" hardline. Overtime the hardline and downpipe would rub

I hope this helps others doing the T4/E4OD swap. I spent a lot of time and too much money getting to this point. This has been the best outcome so far, hopefully it works. I am sure there are other ways to do this. Please share if you have one!

Thanks.

Rusty

1 - Edelmann #822560 5/16" flare to 3/8" tube elbow. $11 at Amazon

The rest of the parts I had from trying to add the SD 3/8" lines and bypass. The front cooler connection is worse with the SD 3/8" bypass/hardline setup. You do need the rear fitting from the bypass to connect the rear hardline. You also need the aluminum spacers https://www.strictlydiesel.com/p-2726-4r100-cooler-bypass-******-kit.aspx from Strictly Diesel or another vendor to eliminate the bypass. Clear as mud?

Here is the Edelmann fitting

Here is the fitting installed by itself

A closeup showing the clearance. I may adding an insulating cover for the hose

Here is how I connected to the cutdown hardline

Here is clearance at it's best with the original 5/16" hardline. Overtime the hardline and downpipe would rub

I hope this helps others doing the T4/E4OD swap. I spent a lot of time and too much money getting to this point. This has been the best outcome so far, hopefully it works. I am sure there are other ways to do this. Please share if you have one!

Thanks.

Rusty

Last edited: