ClassicIDI

Member

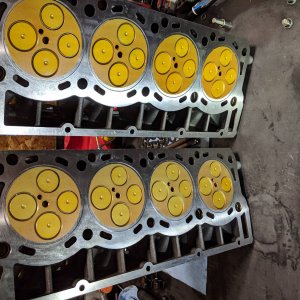

OK follow up from previous post. Truck had a slight miss after new heads and studs and installed with no codes and passed power ballence. Tore injectors back out to find 6 out of the 8 were blowing combustion past copper washers. The two that sealed were the two that had the "long" injector cups installed. #6 was the worst and had almost lost the bottom oring. All injector hold downs were still tight when removed and none of the orings were cut.

Upon closer examination the 6 that are leaking all leaked in the same place opposite the the injector hold down bolt. Half the washer is clean and crushed but half is not crushed and leaking badly. Verified the correct hold downs are being used.

When orings (old copper left installed) are removed from the injector and its installed. The bolt feels like it bottoms in the hole and just stops. At this point I can wiggle the injector around and it's clearly not tight. Injectors were reused from old heads and had no issues for 60k. New Motorcraft orings and coppers installed when heads went on.

Machine shop has never seen this and out of ideas. These are supposed to be reworked OE Ford heads.

Ideas before I pull the heads back off?

Upon closer examination the 6 that are leaking all leaked in the same place opposite the the injector hold down bolt. Half the washer is clean and crushed but half is not crushed and leaking badly. Verified the correct hold downs are being used.

When orings (old copper left installed) are removed from the injector and its installed. The bolt feels like it bottoms in the hole and just stops. At this point I can wiggle the injector around and it's clearly not tight. Injectors were reused from old heads and had no issues for 60k. New Motorcraft orings and coppers installed when heads went on.

Machine shop has never seen this and out of ideas. These are supposed to be reworked OE Ford heads.

Ideas before I pull the heads back off?