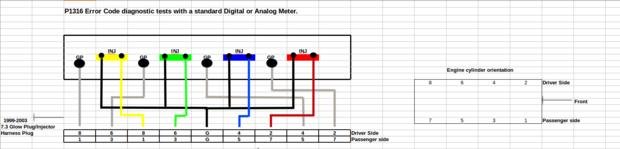

Today I replaced the passengers side connector. The clip was broke and the wires didn't look good either. I could tell they had been hot. After I replaced it they were all in spec but not consistent. From 2.8-3.5. The other side clonnector looks fine and wires look good. One injector reads 12.5ohms on the first test. After stripping back the plastic flex and inspecting wires plugged back in 10.9 ohms. 2 were 2.9 the other was 3.5 which was down from 4.1 on original test. More inspecting test again back to 12.5 and the other above 4 ohms. The other 2 was 2.9 consistent. Going to Ford Tuesday and get wiring harness for both valve covers. My gpr is ford oem just replaced a year ago. Obviously there's a problem in the harness under the valve cover. Power to each side tested goodit was open and shields tested open. So solenoids must be ok and open power circuit. I think while Im down in here I'll go ahead and do a CCv mod. There's oil puddled up in inlet to the turbo and all in the intercooler pipes. If I had my bellowed upipes I'd go ahead and do those to but there in my rv down SC. I'd like to go ahead rebuild the turbo but might as well wait till I do the upipes. Oh well with over 300k miles it's something all time. I'd like to just tear it all down rebuild back.

Merry Christmas Everyone!! God Bless Us and hope Eveyone has a prosperous and healthy New Year!

-------------------------

1st and foremost, Merry Christmas to you too!!

On your turbo and up-pipes, yeah, best to wait until you have those up-pipes in hand.

I was lucky enough to have read about those up-pipes while I had my trans pulled. They were easy to replace with the trans out. Because of that, I didn't have to yank the turbo, just the 'Y' pipe. The 'Y' pipe needed the flange surfaces cleaned up a bit from a wire wheel, and I chased the threads with a metric tap (M8 x 1.25? I think), but that's all I did to it. The clamp was in good shape so I reused it. I was fully prepared to yank the turbo and pedestal (Pedestal 'O' ring kit), but simply didn't need to.

On your injector coils: it really sounds like you've got some issues there. Mine were all balanced in their measurement, none being out of whack at all. I know that doesn't make you feel good (It wouldn't me), but facts are facts. If you have to change the injectors, it's a job, but worth every penny spent. Besides, at 300K miles, you're due anyway. It's common knowledge these engines can go a good 500K before they need a full rebuild- if you take care of them (air, oil fuel filter changes, etc). But yeah, you'll be putting some money in them along the way.

Regardless of which way you look at it, it's still cheaper than a new truck. Even if you were to throw a reman long block in there, that's only 5K for a new one. If you bought a new truck like my neighbor just did, he's now got payments for a $38K truck (Dodge gasser, nice truck sucky payments).

His payment will tip the scales at around $600 or more a month. Gee whiz, at that rate, if you buy a reman long block to install, you'd be done paying it off in about 10 months, all things equal.

Anyway, those gasket/wiring looms can be a pain in the arse to troubleshoot, which is why I logged my findings. Oh, and if you removed the little air breathers on the valve covers, grab the O-rings that fit under them. You'll need to replace them because you'll never get them back into the hole they came out of, they swell up from oil penetration.

If you were able to remove the valve covers without taking them off, you're golden. When I had my covers off, I took the opportunity to swap out my glow plug relay, install new OEM glow plugs (they're cheap, do it now!), change my fuel filter, clean my air filter (I run a K&N) and do an overall inspection.

Keep us posted on your findings. I am very curious about the resistance measurements you are getting on your injector coils.

Oh, and if I were you, I'd change the battery in my volt meter. If you're getting inconsistent continuity readings, the battery may be weak. That is the first thing I do when the measurements are all over the board. Those coils (and glow plugs) should be consistent across the board. Like I said before, if they're not, you have resistance from burned contacts on the hardness, open wires, or a bad coil or glow plug.

Glow plugs should be a dang near short (1 ohm) to work correctly. They work on current draw to heat up, NOT voltage. That's why your harness will show evidence of heat on the connectors.

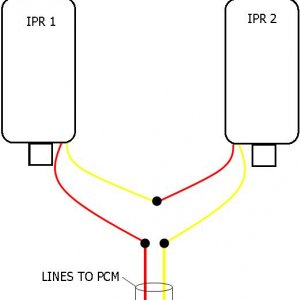

injector coils on the other hand are opposite. Essentially they work on voltage, not current. That's why when you boost your IDM output voltage with the resistor modification, they will work a bit better because depending on the IDM part number, you are upping the game from 100, 110, 120 volts to 140 volts. Folks have reported a crisper throttle, idle as smoother. In a stock engine situation, most felt a power increase. Not so much in a highly modified engine. You can't get much more than the limit of the hardware, law of diminishing returns applies here.

As far as I know, I have seen no reports of damage to injectors or of the IDM whatsoever by doing so and the mod has been employed for several years now. You can see how to do it by searching the net. Nothing new there.