gnxtc2

Active member

So I was bored yesterday.....went to the truck supply place and picked up:

- (1) 5" 90°

- (3) 5" 45s

- (1) 5' length of 5" pipe

- (1) 2' length of 5" pipe

- (1) 4"-5" adapter

- (2) 3' length of 3/8 rod

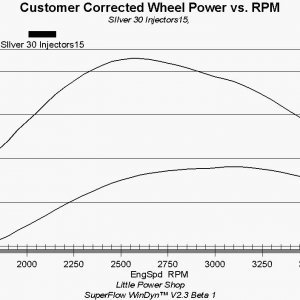

Cut out the old pipe and welded up some 5". I lowered the exhaust slightly in the back. When I raised the truck on the lift, the leaf springs would rest on the exhaust.

The 5" exhaust is much quieter than the 4" with a bullet muffler. Plus there is no drone.

My regret is not removing the stickers off the fitting prior to me installing it.

I do have a a 38 rear tank with the spare. I had to trim the rear tank skid plate at the corner.

Should I put a tip on it or leave it be?

Plus this my second time using the MIG welder.

Billy T.

[email protected]

- (1) 5" 90°

- (3) 5" 45s

- (1) 5' length of 5" pipe

- (1) 2' length of 5" pipe

- (1) 4"-5" adapter

- (2) 3' length of 3/8 rod

Cut out the old pipe and welded up some 5". I lowered the exhaust slightly in the back. When I raised the truck on the lift, the leaf springs would rest on the exhaust.

The 5" exhaust is much quieter than the 4" with a bullet muffler. Plus there is no drone.

My regret is not removing the stickers off the fitting prior to me installing it.

I do have a a 38 rear tank with the spare. I had to trim the rear tank skid plate at the corner.

Should I put a tip on it or leave it be?

Plus this my second time using the MIG welder.

Billy T.

[email protected]

Last edited: