JD3020

Active member

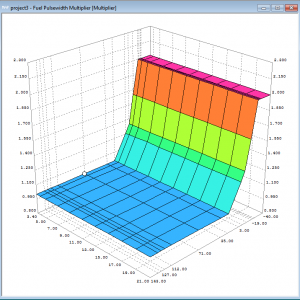

Whats the minimum installed height that i can safely run with 910's? I did the calculations the other night, and it looks like 1.680" installed height is going to bind, according to the Comps specs and that our 7.3's have .400" lift, which i found on here somewhere.

Reason i ask is i'm shooting for an installed height of 1.750, which would put me at 134lbs of seat pressure. But i'm on the 1st valve, and if i use a .060" shim, i'll be at 1.745".

Is that a safe installed height? And would it be beneficial to go any tighter? Plans are to push this engine with a stock-appearing charger, so i'll likely run into a lot of backpressure and don't want to float an exhaust valve.

Reason i ask is i'm shooting for an installed height of 1.750, which would put me at 134lbs of seat pressure. But i'm on the 1st valve, and if i use a .060" shim, i'll be at 1.745".

Is that a safe installed height? And would it be beneficial to go any tighter? Plans are to push this engine with a stock-appearing charger, so i'll likely run into a lot of backpressure and don't want to float an exhaust valve.

Last edited: