7.3L DIT 1994-1998.5

The direct injection engines get a little more

interesting. Riddle me this: when are three different

crankshafts actually two? When they are

used in the 7.3L DIT engine.

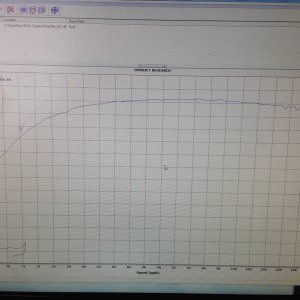

The first two crankshafts are considered the

same product. The only difference between them

is the size of the hole bored into the rod throws.

One (c/n 1818200C1) has 1-1/8˝ bore balance

holes in the rod throws and the other (c/n

1818200C3) has 1˝ bore balance holes drilled in

them. The diameter of the balance hole was

changed for better strength and reliability.

Despite this difference, these cranks are considered

the same and are fully interchangeable

(Figure 9). Use either of these cranks in serial

number engines 501 through 661,973.

Figure 5 The 7.3L IDIT block is stronger, with a 1/4˝

pipe thread for the turbo oil feed. The non-turbocharged

block has a 1/8˝ hole for the oil pressure gauge.

1/4” Pipe Thread

Turbo Block Only

Non-Turbo 1/8”

Figure 6 First series 7.3L DIT blocks had a large

opening at the upper valley area of the cylinder head

deck.

Figure 7 The second series 7.3L DIT block casting has

solid casting support areas between each cylinder bore

as well as additional crank counterweight clearance in

the lower block.

Figure 8 All IDI and IDIT engines in both 6.9L and 7.3L

sizes use the same crankshaft (c/n 1085420C1).

Rebuilding The Ford 7.3L Powerstroke Engine

www.engine-7.3L DIT 1998.5-2004

The third crank (which is actually

the second design) has no

balance hole in the rod throw at

all and has a slightly different

configured counterweight. This

crank can only be used in the

later block casting (c/n

1825849C1) which has the

clearance (Figure 10). This

crank is used in serial number

661,974 through 2,030,402