I had posted this as part of my log thread over on PSN but figured I would post it here as IMO this is going to become more of an advanced board given the membership.

After a failure of a very popular pump with a traditional setup and then one trying the all in one FASS units along with the numerous results of others with failures of Walbro pumps for various reasons I decided to start with a clean slate and work the issues from the ground up. Basically I was not happy with any of the current wheels we use so I decided to reinvent a new one.

For more complete detailed info you can reference my build thread "The Never Ending Build" if you so choose

The issues again addressed are:

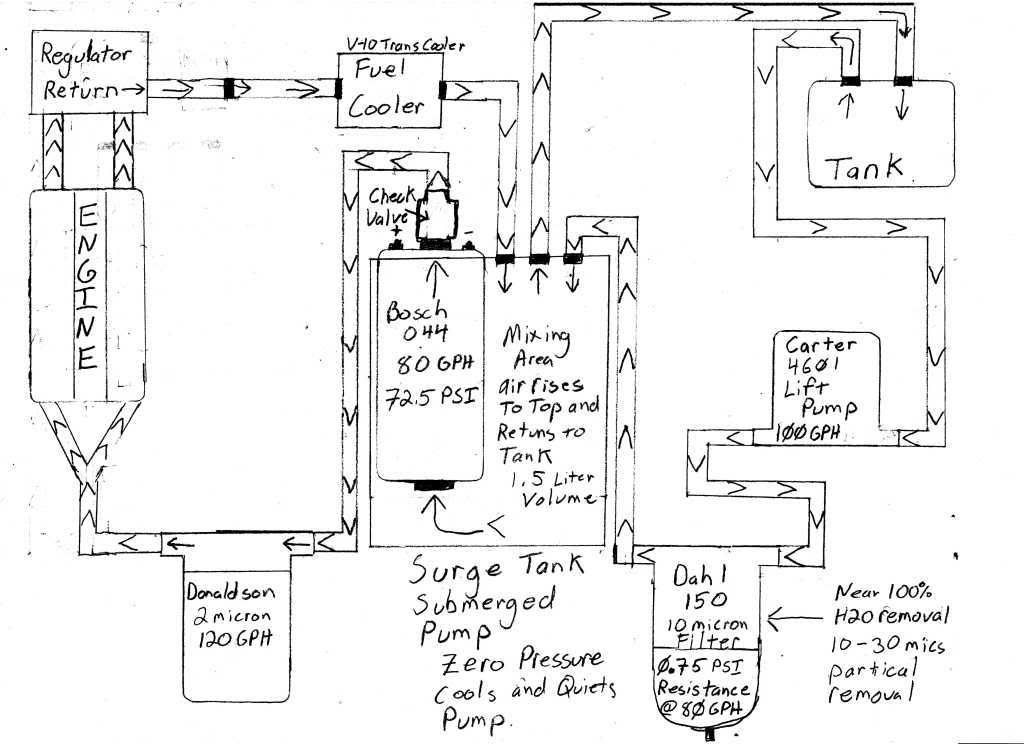

First up will be a rough hand scribbled schematic I drew up when I was crunching all the info I had collected.

The fuel flow direction legends and hose make it look more complicated than it really is. When you break it down it only has a couple more connections than current systems and no more than a system using a Air Dog or FASS as a lift pump. Look at it for a bit and consider things like how the surge tank works and everything it actually does etc..

Look at the hose and flow routing carefully as its easy to misinterpret the flow and think there might be issues.

Then here are some of the pictures I took while I was putting it all together and installing it:

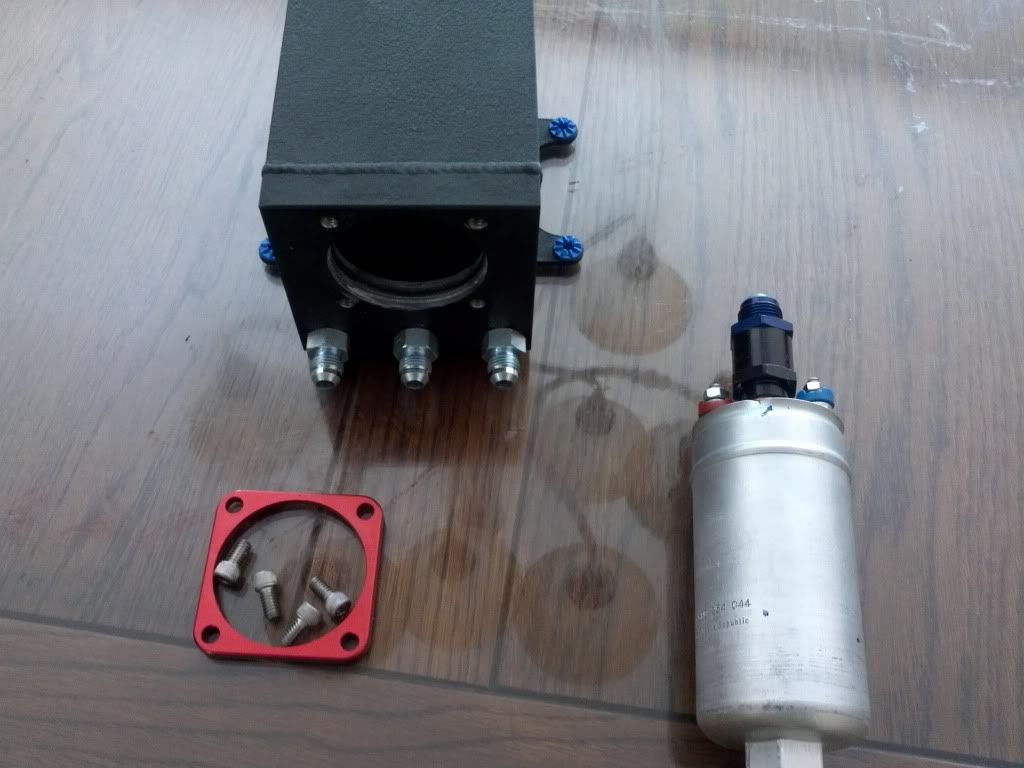

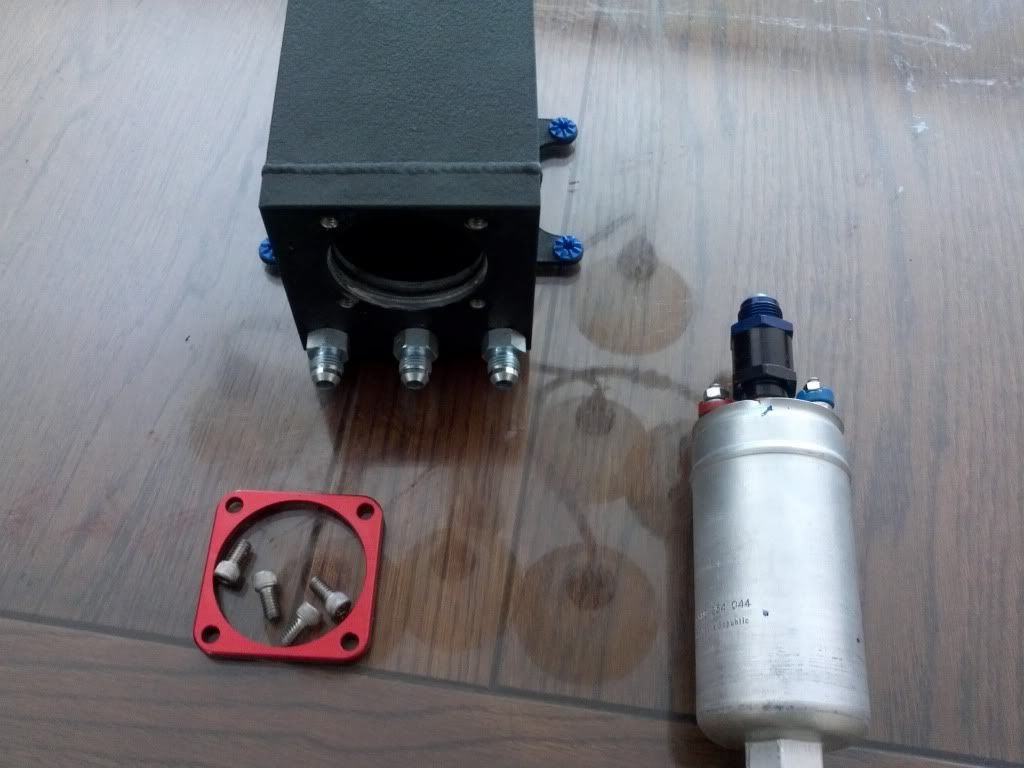

The pump is a Bosch 044 they are basically a unscaled version of our SD pump model

These next few are of the Surge tank. This one showing the pump and 3x-6an ORB ports

This one you can see a close up and see the O-ring inside to help seal the pump to the tank.

These next few show the pump surge tank with its clamping ring.

Jay Racing's Check valve installed on the Bosch pump's outlet.

Pump and surge tank and clamp ring and hardware.

Pump installed in the surge tank.

A few pictures right to left of Carter 4601 pump > Dahl 150> Surge tank with Bosch 044 pump on mounting plate.

Notice I have just a few left over fittings and supplies from all the testing :doh:

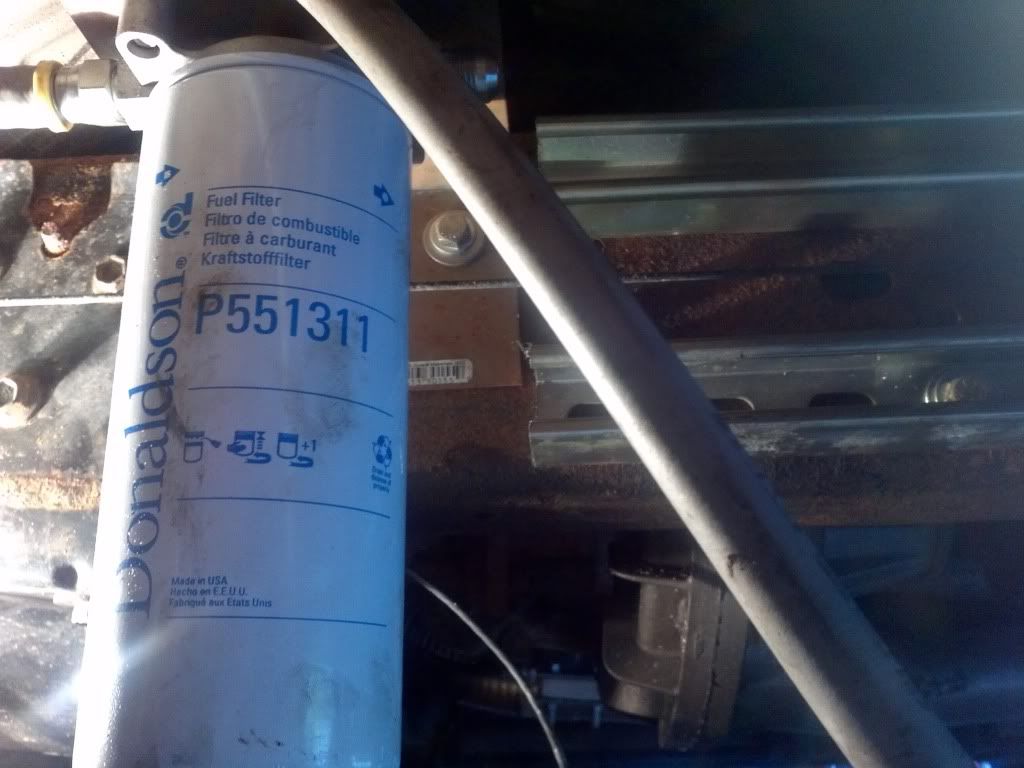

On separate mount the Baldwin 1311 filter base with Donaldson P551311 3 micron absolute single pass perf nominal should around 1 mic recommend flow rate 120 gph.

V10 Trans cooler to be used as the Fuel cooler mounted in grill/bumper.

C-Channel mounted to frame rail uses 3/8" locking spring nuts to mount fuel system plate to it.

The pump is a Bosch 044 pump. Its actually rated for constant pressure from 0-100 psi. There is very little effect on flow from pressure changes compared to many other pumps. But @ 70-75 psi it flows on average 80gph. It has the same internal build as our stock pumps just larger. Its about 25% larger than a Walbro. I learned a lot from speaking with a guy Kevin? at the Bosch tech dept.

The Carter 4600 series pumps have proven to be very durable and long lasting as they are a rotary vane pump so nothing to burn up. They are specifically marine and diesel rated. They are low pressure only and changes in it significantly effects the flow rates. 100 gph free flow which is how it is run in this system.

The Dahl 150 has a pressure resistance @ 80gph flow rate (its recommend flow rate) of 0.75 psi, so very small effect.

The Surge tank is tig welded alum tank. It has 3x -6an threaded ports and the pump port. The pump port is specific fit for the Bosch 044 pump it has a o-ring and works with the clamp again the ring/rim built into the Bosch pump case.

Surge tank has 1.5 liter accessible capacity for the pump (total internal capacity is closer to 3 liters. More could be accessed with the addition of a fitting to the pump inlet)

Dimensions external: 5.5"x8x"4.25"

It sets the pump so its 75% submerged

The 3 ports are -6an ORB threaded

Hoses are -10an from the 5/8 Tank pick up to the Carter. Carter is direct fit into the Dahl 150. _8an hose into the -6an port on the surge tank. -8an from the Bosch pump's check valve into the Baldwin Filter base. -6an hose to the Y . -6an hose into rear inspection port DI fittings on each head. -4an hose out the front top fuel ports exiting the heads into the regulator. -6an hose out the reg return port into the V-10 cooler. -6an hose out of cooler into the surge tank. -6an out of surge tank into old stock feed port on tank sending unit.

Each pump is wired to its own 30 amp Bosch relay that are fused protected from the feed line from the battery. Grounds go directly to battery - post and frame ground bolt. Factory fuel pump wiring harness used as control wires for the relays. All power and ground wires are 10 gauge ultra fine stranded wire.

After a failure of a very popular pump with a traditional setup and then one trying the all in one FASS units along with the numerous results of others with failures of Walbro pumps for various reasons I decided to start with a clean slate and work the issues from the ground up. Basically I was not happy with any of the current wheels we use so I decided to reinvent a new one.

For more complete detailed info you can reference my build thread "The Never Ending Build" if you so choose

The issues again addressed are:

- high volume flow and high psi to support 80gph @ 75psi (800HP+)

- head fuel rail port size

- maximum flow thru heads and effectiveness of regulator to pressure and flow changes

- Pump cooling and lubrication

- Controlling fuel temp (ideal 60° F for max performance in BTU and lubricity)

- Eliminating 1/4 tank and below sloshing issues with intake of air

- Free-Air removal from turbulence and other causes that free entrained air

- Maximum removal of water and absolute particles down to 2-3 microns

- Minimize pump noise levels (stock or better)

First up will be a rough hand scribbled schematic I drew up when I was crunching all the info I had collected.

The fuel flow direction legends and hose make it look more complicated than it really is. When you break it down it only has a couple more connections than current systems and no more than a system using a Air Dog or FASS as a lift pump. Look at it for a bit and consider things like how the surge tank works and everything it actually does etc..

Look at the hose and flow routing carefully as its easy to misinterpret the flow and think there might be issues.

Then here are some of the pictures I took while I was putting it all together and installing it:

The pump is a Bosch 044 they are basically a unscaled version of our SD pump model

These next few are of the Surge tank. This one showing the pump and 3x-6an ORB ports

This one you can see a close up and see the O-ring inside to help seal the pump to the tank.

These next few show the pump surge tank with its clamping ring.

Jay Racing's Check valve installed on the Bosch pump's outlet.

Pump and surge tank and clamp ring and hardware.

Pump installed in the surge tank.

A few pictures right to left of Carter 4601 pump > Dahl 150> Surge tank with Bosch 044 pump on mounting plate.

Notice I have just a few left over fittings and supplies from all the testing :doh:

On separate mount the Baldwin 1311 filter base with Donaldson P551311 3 micron absolute single pass perf nominal should around 1 mic recommend flow rate 120 gph.

V10 Trans cooler to be used as the Fuel cooler mounted in grill/bumper.

C-Channel mounted to frame rail uses 3/8" locking spring nuts to mount fuel system plate to it.

The pump is a Bosch 044 pump. Its actually rated for constant pressure from 0-100 psi. There is very little effect on flow from pressure changes compared to many other pumps. But @ 70-75 psi it flows on average 80gph. It has the same internal build as our stock pumps just larger. Its about 25% larger than a Walbro. I learned a lot from speaking with a guy Kevin? at the Bosch tech dept.

The Carter 4600 series pumps have proven to be very durable and long lasting as they are a rotary vane pump so nothing to burn up. They are specifically marine and diesel rated. They are low pressure only and changes in it significantly effects the flow rates. 100 gph free flow which is how it is run in this system.

The Dahl 150 has a pressure resistance @ 80gph flow rate (its recommend flow rate) of 0.75 psi, so very small effect.

The Surge tank is tig welded alum tank. It has 3x -6an threaded ports and the pump port. The pump port is specific fit for the Bosch 044 pump it has a o-ring and works with the clamp again the ring/rim built into the Bosch pump case.

Surge tank has 1.5 liter accessible capacity for the pump (total internal capacity is closer to 3 liters. More could be accessed with the addition of a fitting to the pump inlet)

Dimensions external: 5.5"x8x"4.25"

It sets the pump so its 75% submerged

The 3 ports are -6an ORB threaded

Hoses are -10an from the 5/8 Tank pick up to the Carter. Carter is direct fit into the Dahl 150. _8an hose into the -6an port on the surge tank. -8an from the Bosch pump's check valve into the Baldwin Filter base. -6an hose to the Y . -6an hose into rear inspection port DI fittings on each head. -4an hose out the front top fuel ports exiting the heads into the regulator. -6an hose out the reg return port into the V-10 cooler. -6an hose out of cooler into the surge tank. -6an out of surge tank into old stock feed port on tank sending unit.

Each pump is wired to its own 30 amp Bosch relay that are fused protected from the feed line from the battery. Grounds go directly to battery - post and frame ground bolt. Factory fuel pump wiring harness used as control wires for the relays. All power and ground wires are 10 gauge ultra fine stranded wire.

Last edited: