F-127

New member

- Joined

- May 25, 2011

- Messages

- 13

- Reaction score

- 0

Alright, doing(should say did) a complete engine teardown. I have a 03 F-250 equipped with a 6.0 with 203k miles. Looking for opinions on things to do or something I may have overlooked. No major issues with the engine, had a moderate exhaust leak at the manifold on one port, EGR system was still present. Previous owner had been running intake/exhaust/tuner but that's about it. Doing some preventative maintenance got carried away into complete teardown since I'm looking for a nice DD year round. Not an unlimited budget but I'm looking to do things right once(hopefully).

The ride:

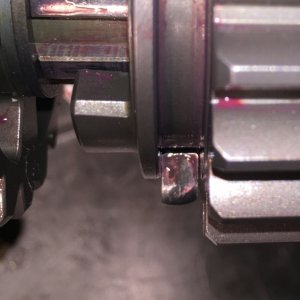

Me getting carried away:

Things at the machine shop:

Block decked, initial talks with machine shop, block needed .005-.008 to be trued up. Cylinder bores, perfect, honing to be completed. Balancing the rotating assembly. Pistons, cut as needed from decking block. Cylinder heads to be checked over.

Things from Ford:

Gaskets and seals for complete rebuild, LPOP, HPOP, piston rings/bearings, oil cooler kit, thermostat, glowplugs, cam and crank sensors, turbo pedistal(mine has a TSB out about a moan/droan), fuel pump(ebay), fuel regulator spring at fuel filter housing, turbo drain tube, IPR and ICP sensor

Aftermarket/Other

EGR delete, coolant filter kit, Powermax turbo, ARP head studs, FICM tuning and ECM/TCM rollback from PHP. Going with a 05+ intake horn/elbow and manifold. Edge CTS with EAS pryo and fuel pressure. Fuel banjo bolts(ebay)

I'm considering replacing the HPOP discharge tube, if replaced the only o-rings in the HPO system that weren't touched would be the ones in the line going from the standpipes to the HPO 'logs'. For the turbo supply, I see no issue with the quick connect fitting there instead of the o-ring and hold-down clamp. Considering tapping a couple ports into the upper oil pan for a possible engine oil bypass or extra turbo drain someday.

So anything I'm missing? Any recommendations? I appreciate the help and will keep things posted as they go back together.

The ride:

Me getting carried away:

Things at the machine shop:

Block decked, initial talks with machine shop, block needed .005-.008 to be trued up. Cylinder bores, perfect, honing to be completed. Balancing the rotating assembly. Pistons, cut as needed from decking block. Cylinder heads to be checked over.

Things from Ford:

Gaskets and seals for complete rebuild, LPOP, HPOP, piston rings/bearings, oil cooler kit, thermostat, glowplugs, cam and crank sensors, turbo pedistal(mine has a TSB out about a moan/droan), fuel pump(ebay), fuel regulator spring at fuel filter housing, turbo drain tube, IPR and ICP sensor

Aftermarket/Other

EGR delete, coolant filter kit, Powermax turbo, ARP head studs, FICM tuning and ECM/TCM rollback from PHP. Going with a 05+ intake horn/elbow and manifold. Edge CTS with EAS pryo and fuel pressure. Fuel banjo bolts(ebay)

I'm considering replacing the HPOP discharge tube, if replaced the only o-rings in the HPO system that weren't touched would be the ones in the line going from the standpipes to the HPO 'logs'. For the turbo supply, I see no issue with the quick connect fitting there instead of the o-ring and hold-down clamp. Considering tapping a couple ports into the upper oil pan for a possible engine oil bypass or extra turbo drain someday.

So anything I'm missing? Any recommendations? I appreciate the help and will keep things posted as they go back together.