flocksmonster garage

New member

- Joined

- Mar 16, 2015

- Messages

- 97

- Reaction score

- 0

Hi all,

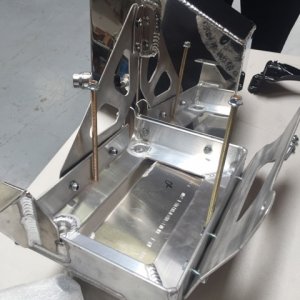

Getting ready to swap a kingpin dana 60 into my 1996 power stroke. I want to put everything it needs on before the swap so it will hopefully go faster, since the truck is my daily driver. I will most likely be going to the local auto parts warehouse for parts. What year/model should I be telling them I need parts for? I think a 1990 4x4 ford f350 power stroke diesel should be correct?

Getting ready to swap a kingpin dana 60 into my 1996 power stroke. I want to put everything it needs on before the swap so it will hopefully go faster, since the truck is my daily driver. I will most likely be going to the local auto parts warehouse for parts. What year/model should I be telling them I need parts for? I think a 1990 4x4 ford f350 power stroke diesel should be correct?