ChunderDownUnder

New member

Ok my engine build has been a learning curve. Unfortunately for me it aint a machine everything up get new parts and put em all together.

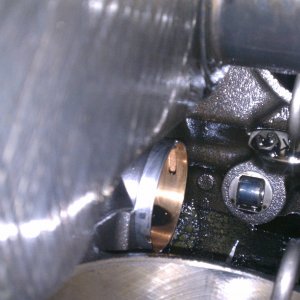

My deck and heads had .003 taken of to clean it up. My crank is .020 undersize on the main journal and .010 under on the big end journal. I have swapped out my PMR's for reman forged. Pistons are .010 oversize OEM. Stock valves. Comp910's install height 1.75 shimmed 134lbs pressure. 3 angle valve job and slight port work which has left me with valve recession of .068 on the intake and .072 on the exhaust. Pistons needed .020 of the top to get me a height above deck of .025. Im running with Matts stage 1 cam and have smith bro pushrods that have .083 wall and +.030 length. Now unfortunately those pushrods are to long due to the amount of meat that has been taken of the engine over its life. So to get the right preload on the rockers (.185 collapsed tappet gap) we have to shim the pedestal .060 to make em work. With all that Im going to end up with a valve to piston clearance of around .110 on the intake and .100 on the exhaust. I cant seem to get a definitive spec on the last bit. I have read .030, .060 and .100. The last number I got from a Swamps post here.

http://swampsdiesel.com/content/projects/Camshaft_Design/

anyone out there who can share their wisdom . And on a serious note if you dont know what ya talking about leave it out. I have been lead up the golden path on these numbers so many times over this build Im really getting over it :fustrate:

My deck and heads had .003 taken of to clean it up. My crank is .020 undersize on the main journal and .010 under on the big end journal. I have swapped out my PMR's for reman forged. Pistons are .010 oversize OEM. Stock valves. Comp910's install height 1.75 shimmed 134lbs pressure. 3 angle valve job and slight port work which has left me with valve recession of .068 on the intake and .072 on the exhaust. Pistons needed .020 of the top to get me a height above deck of .025. Im running with Matts stage 1 cam and have smith bro pushrods that have .083 wall and +.030 length. Now unfortunately those pushrods are to long due to the amount of meat that has been taken of the engine over its life. So to get the right preload on the rockers (.185 collapsed tappet gap) we have to shim the pedestal .060 to make em work. With all that Im going to end up with a valve to piston clearance of around .110 on the intake and .100 on the exhaust. I cant seem to get a definitive spec on the last bit. I have read .030, .060 and .100. The last number I got from a Swamps post here.

http://swampsdiesel.com/content/projects/Camshaft_Design/

anyone out there who can share their wisdom . And on a serious note if you dont know what ya talking about leave it out. I have been lead up the golden path on these numbers so many times over this build Im really getting over it :fustrate: