Hey guys, as our trucks get older all sorts of things start to pop up on us that need repairing or replacing. One of those things is our OBS doornpanels, which are NOTORIOUS for cracking and breaking. The door panels on my 96 F250 were no different.

I had put it off as long as I could. I stuffed them with kleenex to keep them from rattling against the door, epoxied cracks, filled missing chunks with quicksteel putty, you name it. But eventually I just couldn't delay the inevitable any longer. I had to find a more permanent solution. I knew coverlay made replacements, but I just couldn't stomach dropping over $800.00 on two large pieces of plastic. And I didn't exactly want to spend days, weeks, or even months crawling through junked obs trucks on the off chance of finding suitable replacements. Afterall, even IF I found panels in the right color, that plastic would be just as old as mine and would likely be cracked too. So, after many months of procrastination, I decided to fix them.

I acquired a plastic welder off Amazon, along with some ABS sheets, a Rivnut gun with 10-24 rivnuts, and some 10-24 machine screws. My plan was to remove the door panels and fix all the cracks from the inside with the plastic welder, then use the rivnuts and machine screws to re-attach the door in place of the original sheet metal screws (that constantly back out and allow the panel to rattle and crack).

First thing to to was remove the door panels. That procedure is covered on many a youtube video, so I won't go over that here.

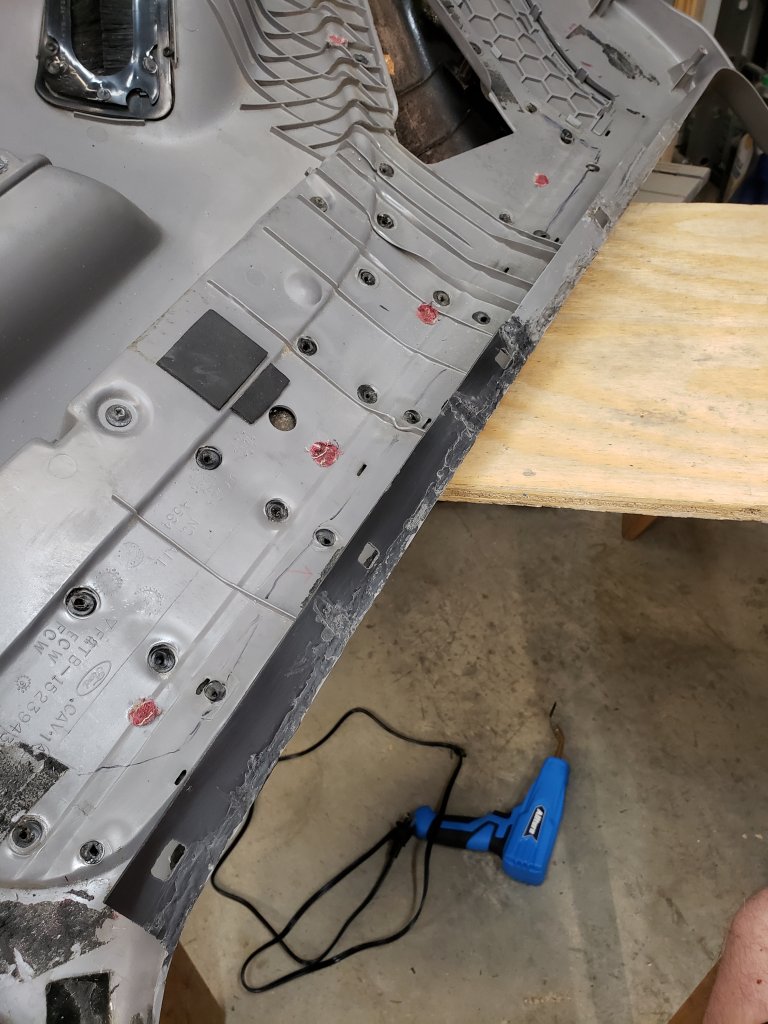

Next was to remove the insullated batting. Originally I considered not going this, but I ended up noticing some previously undiscovered cracks underneath the insullation, so I decided to pull it all of just to make sure I wasn't missing anything else. And it's a good thing I did that, because I was missing some more cracks. So I highly recommend you do the same! To help with reinstalling later, I marked where the edges were with a sharpie all around the inside of the door panel, then I sprayed a dot of red spray paint on the insullation at all the spots where it was glued to the plastic. This way I would know where the insullation was supposed to be and how it should be oriented, as well as where to reglue it.

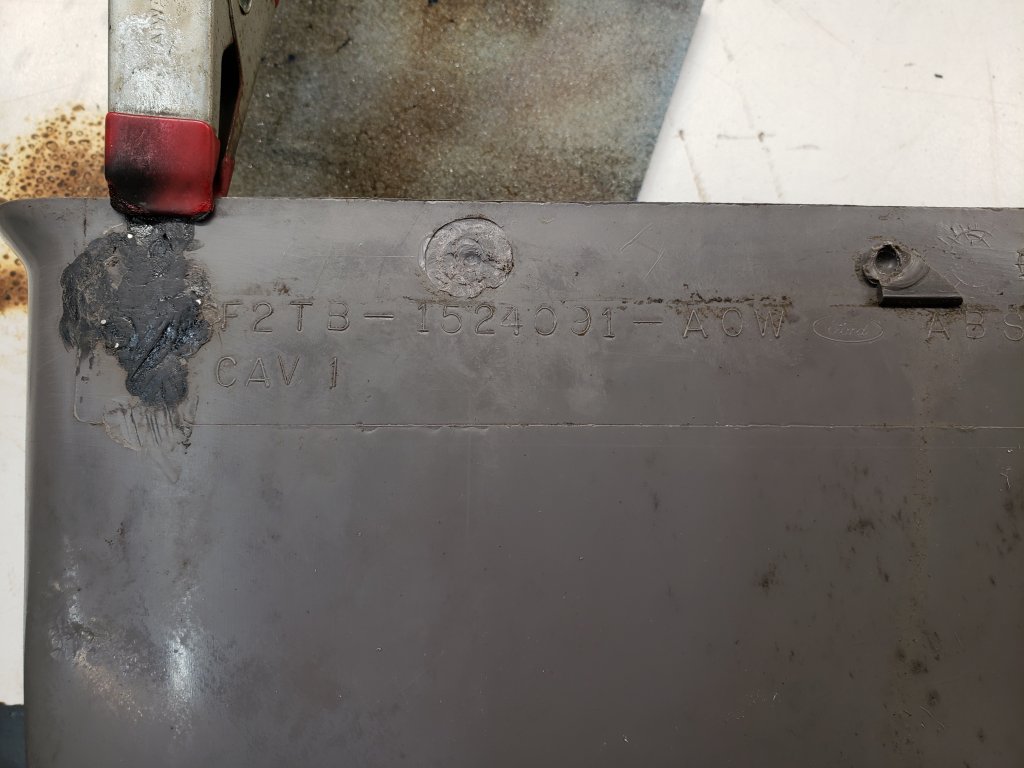

After that I got to work reinforcing and sealing cracks all around the door panel. The plastic welder came with several variations of metal clips. These heat up and sink into the plastic. Then you clip the 2 exposed tabs with snips and sand them flush the rest of the way with a dremel. After that you can use the blade attachment on the plastic welder to reheat the surrounding plastic and smooth it over, even adding some more abs plastic as filler if you want. I got some plastic filler rods on amazon that came in various types (abs, tpo, pe, etc.), but I found that the cut off scraps from the black abs sheets I bought worked just as well, so I mostly used that. I should note that you can ONLY use ABS plastic for this job, other types won't bond to the door panel because the door panel is ABS.

I removed the upper door pouch by drilling out the plastic "tack welds" at the top. Only 2 of the 5 were still holding. The 2 raised tabs that secured the bottom of the pouch were also cracked. Once it was out I was able to repair the crack in the top of the pouch itself. I used the metal clips and some extra filler on the back side.

Then I tried to repair the front with some grey filler to match, but it turned out very ugly and peeled off once it was cool. (This is how I learned that the plastic needs to be ABS, the grey rod I used was NOT abs.) After that I decided to only repair the cracks from the backside of the panel. This leaves the cracks visible from the outside, but it's still less noticeable than the very obvious ugly weld you'd have if you tried to reseal it. And it doesn't seem to be any less strong than having both sides welded.

I reinstalled the pouch by tack welding it back in at the same spots as the factory, then adding in some more filler to beef it up a bit since I removed so much material by drilling it out initially.

I also re-attached the two tabs at the bottom of the pouch by adding a crapload of filler in to beef it up. It was tricky to get the welding gun in at the right angles to make this possible, but I eventually managed.

Then I had to repair a significant chunk of the lip at the top of the door panel. It has square holes in it which the rubber window seal/weather strip attaches to by way of metal clips. Over time most of this lip cracked and broke away.

To fix this I cut a strip out of the abs sheet I bought, then used the rubber weather strip to help determine where the new square holes should be located. I had JUST enough of one hole left to place the rubber strip in position, then I held the plastic lip underneath it and marked the location of the square holes.

I drilled the corners, then used a dremel to rout them out the rest of the way. I cut them undersized at first in case they needed tweaked once this new section of lip was welded onto the door panel. I also had to replace 2 of the boot shaped pieces that run the underside of the plastic lip. To do this I just cut them out and welded them in. But for both the lip and the small boot pieces I had to use a double layer of the abs sheet to get it thick enough. The abs I bought was ever so slightly thinner than the rest of the door panel, and with it doubled up it was slightly thicker than the door panel, but it still worked just fine.

To attach the new section of lip to the top of the door panel, I tack welded it along the top with the blade attachment to hold it in place.

Then I went in along the underside of the lip door panel where the lip meets the top of the panel at a 90 degree angle, and used some 90 degree metal clips to reinforce it.

After trimmimg and sanding all those clips flush I added filler to the crack between the new lip and the top of the door panel.

Then I added in the boot pieces. Those were tricky to maneuver, but I managed. I also trimmed them down a bit with the dremel once they were installed, so they would more closely match the others that were still in place.

I also routed out the square holes a bit more until the rubber weather strip fit properly.

The next thing I had to do was repair one of the plastic shafts that the sheet metal screws go through to secure the door panel to the metal door. One of them had broken off completely.

To do this I cut many small squares of plastic sheeting, then epoxied them together to make a stack that was the same height as the other shafts.

I drilled the center of the shaft to make a hole the same size as the other shafts. It was just slightly larger than the 10-24 screw I planned on using. I then removed the drill bit from the drill while leaving the bit all the way through the square piece, using it as a handle it to hold it and rotate it against the belt sander.

Doing this allowed me to round the corners of the square stack, turning it into a circular shaft to match the others. Then I welded it into the door panel using a combination of the metal clips and filler plastic.

The rest of the cracks I fixed are pretty self explanatory. Just pressed in the metal clips, trimmed and sanded them, then smoothed the cracks over with the blade attachment.

After everything was all repaired I re-attached the insullation with super glue at the points I had marked with red spraypaint earlier. I started at the innermost points and worked my way out and around. A can of activator spray makes this part go a LOT quicker.

Then I just had to put the panel back in the truck! I started by drilling out the old holes with a 7mm drill bit, then installing the rivnuts.

Once all 6 rivnuts were in place (5 for the bottom, one for the top front) I put the panel back on as normal and used the 10-24 screws to secure the panel to the door. I did NOT replace the black plastic body clips, and even without them the door is VERY solid and doesn't rattle at all now!

The cracks are still visible on the outside of the panel, so it's not "perfect". But unless you've got a show truck that you want to keep spotless, this is an affordable way to repair your door panel to be solid and functional. All in it cost me around $200.00 for the plastic welder, plastic abs sheets, plastic filler rod (which I ended up not using), rivnut gun, rivnuts, and 10-24 machine screws. It took 3 or 4 days working a few hours a day to do both front door panels start to finish. So it is time consuming, but a lot of that was due to the plastic welder overheating and having to wait for it to cool down. If you decide to do this job, use the plastic welder to apply the metal clips FIRST as this doesn't get the welder nearly as hot, so you can get more accomplished in one sitting. Then once the clips are in place and sanded down, you can use the blade attachment to smooth them over and add filler. That's what overheats the gun.

Anyway, I hope this helps guys! Let me know if you have any questions.

I had put it off as long as I could. I stuffed them with kleenex to keep them from rattling against the door, epoxied cracks, filled missing chunks with quicksteel putty, you name it. But eventually I just couldn't delay the inevitable any longer. I had to find a more permanent solution. I knew coverlay made replacements, but I just couldn't stomach dropping over $800.00 on two large pieces of plastic. And I didn't exactly want to spend days, weeks, or even months crawling through junked obs trucks on the off chance of finding suitable replacements. Afterall, even IF I found panels in the right color, that plastic would be just as old as mine and would likely be cracked too. So, after many months of procrastination, I decided to fix them.

I acquired a plastic welder off Amazon, along with some ABS sheets, a Rivnut gun with 10-24 rivnuts, and some 10-24 machine screws. My plan was to remove the door panels and fix all the cracks from the inside with the plastic welder, then use the rivnuts and machine screws to re-attach the door in place of the original sheet metal screws (that constantly back out and allow the panel to rattle and crack).

First thing to to was remove the door panels. That procedure is covered on many a youtube video, so I won't go over that here.

Next was to remove the insullated batting. Originally I considered not going this, but I ended up noticing some previously undiscovered cracks underneath the insullation, so I decided to pull it all of just to make sure I wasn't missing anything else. And it's a good thing I did that, because I was missing some more cracks. So I highly recommend you do the same! To help with reinstalling later, I marked where the edges were with a sharpie all around the inside of the door panel, then I sprayed a dot of red spray paint on the insullation at all the spots where it was glued to the plastic. This way I would know where the insullation was supposed to be and how it should be oriented, as well as where to reglue it.

After that I got to work reinforcing and sealing cracks all around the door panel. The plastic welder came with several variations of metal clips. These heat up and sink into the plastic. Then you clip the 2 exposed tabs with snips and sand them flush the rest of the way with a dremel. After that you can use the blade attachment on the plastic welder to reheat the surrounding plastic and smooth it over, even adding some more abs plastic as filler if you want. I got some plastic filler rods on amazon that came in various types (abs, tpo, pe, etc.), but I found that the cut off scraps from the black abs sheets I bought worked just as well, so I mostly used that. I should note that you can ONLY use ABS plastic for this job, other types won't bond to the door panel because the door panel is ABS.

I removed the upper door pouch by drilling out the plastic "tack welds" at the top. Only 2 of the 5 were still holding. The 2 raised tabs that secured the bottom of the pouch were also cracked. Once it was out I was able to repair the crack in the top of the pouch itself. I used the metal clips and some extra filler on the back side.

Then I tried to repair the front with some grey filler to match, but it turned out very ugly and peeled off once it was cool. (This is how I learned that the plastic needs to be ABS, the grey rod I used was NOT abs.) After that I decided to only repair the cracks from the backside of the panel. This leaves the cracks visible from the outside, but it's still less noticeable than the very obvious ugly weld you'd have if you tried to reseal it. And it doesn't seem to be any less strong than having both sides welded.

I reinstalled the pouch by tack welding it back in at the same spots as the factory, then adding in some more filler to beef it up a bit since I removed so much material by drilling it out initially.

I also re-attached the two tabs at the bottom of the pouch by adding a crapload of filler in to beef it up. It was tricky to get the welding gun in at the right angles to make this possible, but I eventually managed.

Then I had to repair a significant chunk of the lip at the top of the door panel. It has square holes in it which the rubber window seal/weather strip attaches to by way of metal clips. Over time most of this lip cracked and broke away.

To fix this I cut a strip out of the abs sheet I bought, then used the rubber weather strip to help determine where the new square holes should be located. I had JUST enough of one hole left to place the rubber strip in position, then I held the plastic lip underneath it and marked the location of the square holes.

I drilled the corners, then used a dremel to rout them out the rest of the way. I cut them undersized at first in case they needed tweaked once this new section of lip was welded onto the door panel. I also had to replace 2 of the boot shaped pieces that run the underside of the plastic lip. To do this I just cut them out and welded them in. But for both the lip and the small boot pieces I had to use a double layer of the abs sheet to get it thick enough. The abs I bought was ever so slightly thinner than the rest of the door panel, and with it doubled up it was slightly thicker than the door panel, but it still worked just fine.

To attach the new section of lip to the top of the door panel, I tack welded it along the top with the blade attachment to hold it in place.

Then I went in along the underside of the lip door panel where the lip meets the top of the panel at a 90 degree angle, and used some 90 degree metal clips to reinforce it.

After trimmimg and sanding all those clips flush I added filler to the crack between the new lip and the top of the door panel.

Then I added in the boot pieces. Those were tricky to maneuver, but I managed. I also trimmed them down a bit with the dremel once they were installed, so they would more closely match the others that were still in place.

I also routed out the square holes a bit more until the rubber weather strip fit properly.

The next thing I had to do was repair one of the plastic shafts that the sheet metal screws go through to secure the door panel to the metal door. One of them had broken off completely.

To do this I cut many small squares of plastic sheeting, then epoxied them together to make a stack that was the same height as the other shafts.

I drilled the center of the shaft to make a hole the same size as the other shafts. It was just slightly larger than the 10-24 screw I planned on using. I then removed the drill bit from the drill while leaving the bit all the way through the square piece, using it as a handle it to hold it and rotate it against the belt sander.

Doing this allowed me to round the corners of the square stack, turning it into a circular shaft to match the others. Then I welded it into the door panel using a combination of the metal clips and filler plastic.

The rest of the cracks I fixed are pretty self explanatory. Just pressed in the metal clips, trimmed and sanded them, then smoothed the cracks over with the blade attachment.

After everything was all repaired I re-attached the insullation with super glue at the points I had marked with red spraypaint earlier. I started at the innermost points and worked my way out and around. A can of activator spray makes this part go a LOT quicker.

Then I just had to put the panel back in the truck! I started by drilling out the old holes with a 7mm drill bit, then installing the rivnuts.

Once all 6 rivnuts were in place (5 for the bottom, one for the top front) I put the panel back on as normal and used the 10-24 screws to secure the panel to the door. I did NOT replace the black plastic body clips, and even without them the door is VERY solid and doesn't rattle at all now!

The cracks are still visible on the outside of the panel, so it's not "perfect". But unless you've got a show truck that you want to keep spotless, this is an affordable way to repair your door panel to be solid and functional. All in it cost me around $200.00 for the plastic welder, plastic abs sheets, plastic filler rod (which I ended up not using), rivnut gun, rivnuts, and 10-24 machine screws. It took 3 or 4 days working a few hours a day to do both front door panels start to finish. So it is time consuming, but a lot of that was due to the plastic welder overheating and having to wait for it to cool down. If you decide to do this job, use the plastic welder to apply the metal clips FIRST as this doesn't get the welder nearly as hot, so you can get more accomplished in one sitting. Then once the clips are in place and sanded down, you can use the blade attachment to smooth them over and add filler. That's what overheats the gun.

Anyway, I hope this helps guys! Let me know if you have any questions.