baddkarmaracing

New member

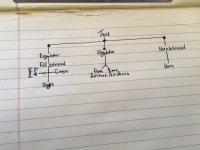

Does this look right? Never done airbags before and I want to make sure I have this setup properly when I do it. The reason for the regulators is the compressors shut off at 200psi which is double what the bags max pressure, and most air tools are rated around 90psi if I remember right. Also what should I use to plumb this? Hard plastic line or regular air hose? Quick connects or barbed fittings? What size should everything be? Also I will add a gauge off the tank somewhere but didn't feel the need to add that to the diagram.