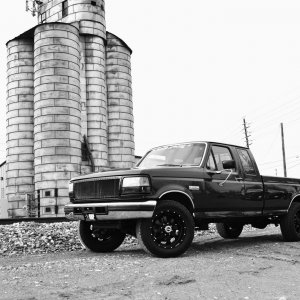

The morning I left the middle of Joshua Tree National Park; 3rd week of January and no bars on the phone. I stopped on the side of the road to take a couple of pics. I left the engine idling. When I walked back around the truck, smoke was coming out from under the driver's side of the hood. I turned it off, grabbed the fire extinguisher and opened the hood. The big (i have 2 air filters) air filter was on fire, so I hosed it down real good. It was a good thing I didn't have the powder type extinguisher.

After much swearing, I decided it would be best to take a few minutes to calm down and think about this.

I grabbed my well stocked tool bag (i never take the truck anywhere without it) and went at it. I removed the damaged air filter and saw the headlight bulb, retainer and wire harness melted. BUT, it turned out to be just the outer plastic melted off the main harness and insulation on the headlight and side marker wires. I seriously thought about having an IPA. I cut the damaged wires and taped them up. I cut a piece of plastic out of a spare cheap rain poncho and clamped that over the end of the intake tube. Having 2 air filters sure came in handy! I started it and could immediately hear the turbo was not right. I removed the tube and saw blade damage.

I needed to pull the trailer about 125 miles back to our boondock camp, which was across some very desolate desert. If I throttled carefully and kept the rpms between 1500 and 1700, it growled the least. I made it back to camp without incident.

At camp with an IPA, I contacted Charlie (KC Turbo) by email. I didn't have his phone number. A couple of IPAs later, I got a response. I would drive to Apache Junction (~155 miles) the next morning and see what could be done?

The drive to KC Turbo went without incident. Driving through Phoenix with the turbo growling, resulted in some nasty thoughts going through my brain.

Once I arrived, we discussed the situation and decided which turbo would be the best replacement? Charlie had a S300 (63/70/84) assembled and in my hands in about 15 minutes. He then hooked me up with a guy who lives about 2 miles away, has a driveway and tools. At about 8 pm, I had swapped the turbos and tested it for leaks.

I took it easy on the drive back, wondering if a turbo needs a break in? I didn't take any chances.

I will do a separate post on my comparison Between the KC TP38r and the new KC S300.

The culprit and I stuffed some paper towels into the filter to see the size of the hole.

After much swearing, I decided it would be best to take a few minutes to calm down and think about this.

I grabbed my well stocked tool bag (i never take the truck anywhere without it) and went at it. I removed the damaged air filter and saw the headlight bulb, retainer and wire harness melted. BUT, it turned out to be just the outer plastic melted off the main harness and insulation on the headlight and side marker wires. I seriously thought about having an IPA. I cut the damaged wires and taped them up. I cut a piece of plastic out of a spare cheap rain poncho and clamped that over the end of the intake tube. Having 2 air filters sure came in handy! I started it and could immediately hear the turbo was not right. I removed the tube and saw blade damage.

I needed to pull the trailer about 125 miles back to our boondock camp, which was across some very desolate desert. If I throttled carefully and kept the rpms between 1500 and 1700, it growled the least. I made it back to camp without incident.

At camp with an IPA, I contacted Charlie (KC Turbo) by email. I didn't have his phone number. A couple of IPAs later, I got a response. I would drive to Apache Junction (~155 miles) the next morning and see what could be done?

The drive to KC Turbo went without incident. Driving through Phoenix with the turbo growling, resulted in some nasty thoughts going through my brain.

Once I arrived, we discussed the situation and decided which turbo would be the best replacement? Charlie had a S300 (63/70/84) assembled and in my hands in about 15 minutes. He then hooked me up with a guy who lives about 2 miles away, has a driveway and tools. At about 8 pm, I had swapped the turbos and tested it for leaks.

I took it easy on the drive back, wondering if a turbo needs a break in? I didn't take any chances.

I will do a separate post on my comparison Between the KC TP38r and the new KC S300.

The culprit and I stuffed some paper towels into the filter to see the size of the hole.

Attachments

Last edited: