You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Search results

-

7.3 no start

you may want to find someone with a clamp on DC ammeter to test your cables and starter- POWER-STRUCK

- Post #4

- Forum: 7.3 Tech

-

97 F350 not starting

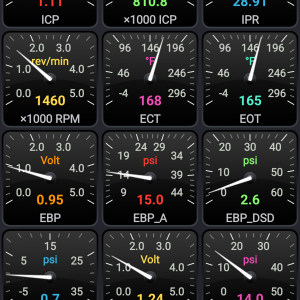

Monitor these while cranking to start. Also monitor RPM, vref, map, baro, ebp, mass fuel desired. I also have diag charts in the tech section of my website that you can print off sent using tapatalk- POWER-STRUCK

- Post #4

- Forum: 94-97 Tech

-

Custom Tunes for a TS 6 Position Switch?

Feel free to call, PM or email me if I can be any help. [email protected] 877-616-Ford 812-689-4200 812-756-0286 sent using tapatalk- POWER-STRUCK

- Post #9

- Forum: 94-97 Tech

-

4R100 Problems

That's a diode sprag "one way clutch" Retrofitting to the older e4od components makes it more reliable. sent using tapatalk- POWER-STRUCK

- Post #23

- Forum: Suspension, Drive Train, and Tires

-

2002 F250, no start dead batterys- need answers asap

any updates? I hope he found the problem- POWER-STRUCK

- Post #11

- Forum: 7.3 Tech

-

New Guy from VA

Welcome to PSA Sent from my DROID RAZR HD using Tapatalk- POWER-STRUCK

- Post #7

- Forum: Newly Enlisted

-

2002 F250, no start dead batterys- need answers asap

Wiring junction under the air box. Eyelets are probably corroded off of the post. Sent from my DROID RAZR HD using Tapatalk- POWER-STRUCK

- Post #9

- Forum: 7.3 Tech

-

BDP chip

should work as long as it is for the same dpc code- POWER-STRUCK

- Post #2

- Forum: 94-97 Aftermarket

-

Core injectors

Christmas is coming. Get me a package price for the injectors, chip,exhaust housing Sent from my DROID RAZR HD using Tapatalk- POWER-STRUCK

- Post #2

- Forum: Aftermarket Performance

-

New Girl from Ontario

Nice Ford. Sent from my DROID RAZR HD using Tapatalk- POWER-STRUCK

- Post #5

- Forum: Newly Enlisted

-

oil cooler troubles

flush with water twice (up to operating temperature then drain) then I run VC9 up to operating temp and allow to cool repeatedly the rest of the day. at the end of the day flush with water twice. drain the system for repairs the next day. (get a designated shop vac for cleaning oil and coolant...- POWER-STRUCK

- Post #16

- Forum: 6.0 Tech

-

Anyone running Power Struck Injectors?

thanks for the support and feedback guys but make sure that you give the guys on this site that specialize in injectors a fair shot also: http://rosewooddieselshop.com/ http://performanceinjectionsystems.com/ http://shop.fullforcediesel.com/main.sc http://www.unlimiteddiesel.com/products.html- POWER-STRUCK

- Post #10

- Forum: 7.3 Aftermarket

-

Newbie from Vegas

Welcome Sent from my DROID RAZR HD using Tapatalk- POWER-STRUCK

- Post #6

- Forum: Newly Enlisted

-

7.3 P1212 code, no start.

Under the clamp near the body of the injector. (The upper orings) Sent from my DROID RAZR HD using Tapatalk- POWER-STRUCK

- Post #11

- Forum: 7.3 Tech

-

New from IN

welcome to the site! thanks Bryan representing- POWER-STRUCK

- Post #5

- Forum: Newly Enlisted

-

7.3 P1212 code, no start.

that should be sufficient pressure to start it and the condition should improve after the engine cools if it is a hpo issue you can either narrow it down by blocking one hpop line at a time or just pull the valve covers and look for gushing injector orings. could even be the center orings but...- POWER-STRUCK

- Post #8

- Forum: 7.3 Tech