This is a summary of a post of mine as twoicebergs to make larger injectors at home or in conjunction with a local machine shop. My post started out as a what-if post and turned into a how-to post with the help of a number of other 6.0 enthusiasts. Search it out on the web and you should find lots of info. Some of this has already been discussed in other posts at the Army, but was not complete. FWIW, I made 4 sets of injectors with the help of a local machinist (I didn't have access to a lathe). He was very hesitant to do what I asked, but after it was all said and done, it was a fairly easy process to do. Both the plunger and intensifier piston can be turned down on a lathe, but care must be taken to not damage the pieces in the chuck. However, for the DLC coated plungers, they were turned down using a diamond lapping wheel.

First some basics:

The plunger bore is 6.34mm in diameter. At rest the plunger sits just above the spill port and at maximum extension it sits 0.025- 0.029" from the end of the barrel, giving about 0.135cc of injection. The raw volume of a stock injector bore at rest is about 177ml! Losses give about 135ml are the end gap (23ml) and the spill port (20ml).

You can increase the stroke to give a chamber volume of about 0.205cc before spill port losses affect the idle or performance characteristics. This will create a flow of just under 0.190cc. If you want to go larger, do the math and be prepared to plug the spill-ports with 3.5mm brass rod or add shims to the top of the fuel plate.

Injectors are expensive. Work carefully because no one will sell you parts.

The barrels and plungers are matched -

KEEP THEM TOGETHER AS A SET - MARK WITH A SHARPIE. The tolerances are very tight. Lilpooh took some measurements using specialized equipment.

Although all the plungers will be about 46.50mm, to ensure a good results, take off specific amounts, do not just make each part the same length. For a 175cc injector modification the plunger needs to be shortened about 0.030" (0.633mm) to convert to a 175 volume. The intensifier piston is about 21.43mm in length. To create the increased stroke, this needs to be shortened 0.050" 1.267mm to create a 175cc injector. Ensure you have 0.005" clearance from the plunger to the end of the bore. If you go tighter, there is the possibility that the plunger will contact the fuel plate at max PW for your injector/nozzle selection. For a 175/75 injector, max fuelling will happen about 2.7ms PW.

<<< I deliberately went tight to the bottom of the bore (<0.001") with the plunger stroke. During a test run in the truck, at a high ICP and a PW of 2.7, my injectors are completely empty. How do I know? Well, I could hear an occasional slight ping. I thought this might happen, so to prevent damage, I initially decrease the PW slightly on my extreme tune, then trimmed the plungers another 0.001". There was no sound after the second trim. When I pulled the injectors to put in new ones with different nozzles, there was no damage or indication of hammer marks on the fuel plates. >>>

I measured other sets of injectors. The intensifier bore depth was out slightly on some of them. I had similar results on the first set as well. Lilpooh had also taken measurements and had one that showed end bore spacing of 0.029", but most of mine were less. I did have a few that were as tight as 0.025". It would be a good idea to measure the shims to see if they are different thicknesses as well to make up for the bore depth. Most of the ones I had seen were within 0.002 of each other.

To ensure a buffer of 0.005" for the plunger to fuel plate clearance, for any amount cut from the intensifier piston, cut 0.020" less off the plunger. For the plunger I would only cut 0.035" max off the hammer end of the plunger, and cut any remaining amount from the clevis end if you wanted larger injectors.

So for 190cc injectors, the chamber would need to be 6.63mm deep to keep the plunger safe from bottoming out. and the total stroke would be 6.5.mm. Again, keep in mind the plunger in a stock injector sits about 5.6mm from the fuel plate at rest (volume 177ml) but does not travel full length (loss of 22ml) and looses some out the spill port to give about a 135 injector. This is why a simple 3.5mm plug gives you a 155cc injector. This is also why you don't necessarily need to cut 0.087" (2.21mm) off the intensifier piston to achieve the desired travel for a 190cc injector. You could, but it is not as efficient as moving the plunger down the bore.

For a 190 injector cut about 0.065"off the intensifier piston and 0.045"off the plunger. Remember that the 0.035" you take off the bottom of the plunger does not affect the DLC wall or even the spill-port interaction. You could cut a bit more off (0.005"-0.010"), but the gain would be marginal at best and only at WOT.

For my first set of nozzles I used 75% over nozzles that were extrude honed by Chatham Fuel Injector Services in Canada. My second set were honed to 50%. To do it all over again, I would just buy the nozzles from Poltron Diesel Injectors.

When reassembling injectors do not over-torque the spool cross-bolt!

I believe the torque values are:

Cross bolt = 0.5 Nm (very little torque) - this is probably why some break after a rebuild or inspection. I used a lot more torque to remove them!

Two hold down bolts = 3 Nm (a bit more torque)

Nozzle nut = 55 - 60 lb/ft** (I came across 85 in a post somewhere, but that may have been a transcribing error?)

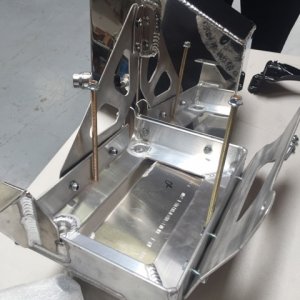

Here they are idling in the truck after installation.

https://www.youtube.com/watch?feature=player_detailpage&v=LwKTc7r39fU#t=0

I only had the SCT Performance tune on it for the installation, just to see how it behaved on start. If I go WOT, I get hazing, but the temps are quite good; all probably due to the 75% nozzles. Anything under 50% pedal was clean. There is no doubt a bigger turbo is needed if you plan on playing hard - but that is another thread.