Honestly - I would like to see a back to back comparison with just a swap to the 87mm turbine wheel - personally I think its a better wheel and don't believe you would have any area suffering by making the swap and pick up some top end as well as reducing back pressure - BUT I have never done a back to back test with that being the only difference. I'm getting ready to put together a set of compounds for a guy and plan on using the 87mm turbine wheel in the high pressure charger.

I used to run the 87 wheel in the T4i housing. This turbine

is more driveable then that turbo was, but the power difference is also noticeable top end.

With that being said, the 87mm wheel according to Forced inductions isn't put in the T4 anymore. Has to do with it causing the casting to be too thin and cracking.

I do know there are guys out there that have a turbo setup like that ie: Craig Briggs.

Personally I'd like the try the wheel forced inductions says will flow more then that wheel anyway... it's supposed to be a 92/82 wheel that mimics the GT-47 wheel. IDK, but with how driveable this is, a larger turbine is definitely ok with me.

What size Turbine housing are you going to go with??

I'm assuming you're asking that based on HRT's comment. IDK if you're thinking along the same lines as in the T4 housing has a cracking issue with the 87 turbine or not. But I assume you are. If you are asking me... I'm staying with what I have for now. Kind of up in the air (lol) about what to do next.

Had a chance to ride in the platinum last night and it pulls HARD! It'll definitly give my race tuned 6.4 a run for its money and I'm pretty sure he was still in his hot street tune! It's alot less smokey than I expected also, don't get me wrong it'll make some smoke when your on the skinny. But if you use some sense it's daily drivable no problem.

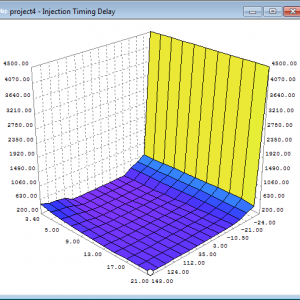

The wastegate is opening in both tunes so the difference between the two tunes is pretty much negligable.

Nice to see youre cleaning up some of that mess you had under your hood for the longest time...

I think you should do some back to back runs some with the air filter off. That standard paper media is a big restriction under higher boost levels i guarantee you'll pick up some more PSI just from that. Look into putting twin filters for cheap or put a big expensive single one in its place.

For the wastegate i think using air instead of the mechanical spring is the best way to go about it. I know its a bitch to get to it to take it off, but i would recommend putting the 10psi spring in it, putting unregulated manifold pressure to the bottom, and regulated boost to the top. Put the regulator to shop air and set it at 50psi (thats all that you'll have pushing on the top of the diaphragm) and begin tweaking it a 1/8 or so turn either way until you are happiest with it. Who is tuning it?

Running with or without the air filter shouldn't matter as the wastegate is limiting boost/drive, correct?

On my previous setup, I ran with and without a paper filter at the track. The difference was only a couple of PSI and that was on an unwastegated setup - 60-63 psi if I recall correctly. I don't recall any drive numbers so that's why I'm starting threads like this with actual data logged.

At any rate it wouldn't take but two seconds to take that filter off and try what you're speaking of.

Swamps tuning. The wastegate is staying as is.

What's everybody think about the boost/drive ratio? 50:60 basically so 1.2:1.

At 40 psi it's still 1:1.