DZL JIM

Member

Got a 2005 6.0 customer's truck here we are totally stumped with and I need some outside, fresh input what to look at.

We replaced 4 injectors and the oil pan for the customer. Afterward we fired up the truck and it won't idle. You have to feather the throttle to get it to fire, and you can hold it around 825 rpm and it runs great, will rev and run fine above that.

It fires and instantly dies, unless you feather the throttle to keep it running.

When it is running as soon as you let off the throttle it dies.

We have no idea if it was an existing condition or not as all 4 injectors were dead when it was delivered and you had to be aggressive with the throttle to make it run anyway.

Cam sensor code keeps coming back.

We replaced the ECM twice, swapped in a reman FICM, swapped in 2 different crank sensors, 2 different cam sensors, new IPR.

Unplugged the throttle pedal and even swapped it with another one.

Nothing we have done will make it idle.

I have unplugged every sensor not critical for firing and idling with no change, with the exception that when I unplug the Exhaust Back Pressure Sensor it will fire and idle for exactly 2 seconds then die.

The turbo test checks out with good Baro, MAP and EBP all matching at 14.

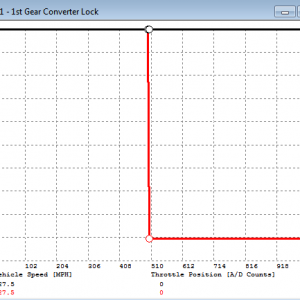

I datalogged the event when it dies with IDS watching ICP and IPR duty cycle. Both ICP and DC don't change until rpm's reach around 500 rpm (drop from 825), so I really don't think it's a High Pressure Oil issue --causing-- it to die.

We can't be the only one to run into this.

Any help or direction is greatly appreciated.

EDIT: Low pressure oil is perfect at all times at 60 psi. Fuel pressure is solid at all times at 55 psi. Fuel filters are new, as is engine oil and filter (new oil pan).

We replaced 4 injectors and the oil pan for the customer. Afterward we fired up the truck and it won't idle. You have to feather the throttle to get it to fire, and you can hold it around 825 rpm and it runs great, will rev and run fine above that.

It fires and instantly dies, unless you feather the throttle to keep it running.

When it is running as soon as you let off the throttle it dies.

We have no idea if it was an existing condition or not as all 4 injectors were dead when it was delivered and you had to be aggressive with the throttle to make it run anyway.

Cam sensor code keeps coming back.

We replaced the ECM twice, swapped in a reman FICM, swapped in 2 different crank sensors, 2 different cam sensors, new IPR.

Unplugged the throttle pedal and even swapped it with another one.

Nothing we have done will make it idle.

I have unplugged every sensor not critical for firing and idling with no change, with the exception that when I unplug the Exhaust Back Pressure Sensor it will fire and idle for exactly 2 seconds then die.

The turbo test checks out with good Baro, MAP and EBP all matching at 14.

I datalogged the event when it dies with IDS watching ICP and IPR duty cycle. Both ICP and DC don't change until rpm's reach around 500 rpm (drop from 825), so I really don't think it's a High Pressure Oil issue --causing-- it to die.

We can't be the only one to run into this.

Any help or direction is greatly appreciated.

EDIT: Low pressure oil is perfect at all times at 60 psi. Fuel pressure is solid at all times at 55 psi. Fuel filters are new, as is engine oil and filter (new oil pan).

Last edited: