jrex2506

Member

- Joined

- Oct 24, 2013

- Messages

- 527

- Reaction score

- 0

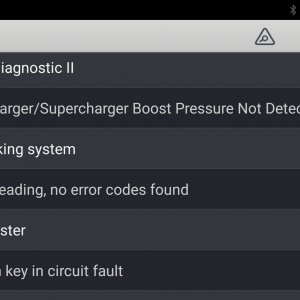

Truck was running good and stock turbo blew on me and i replaced the turbo with non vgt. I found shavings, possibly brass colored in the filter housing i thought were from the turbo bearings.

Now i had the truck stumbled coming up a mountain, and a p2285 code. I went ahead and replaced the icp and pigtail. Cranking when cold takes a long crank to build icp, once it hits 500 its starts. So dont think its the sensor or pigtail. At 32 degrees cold idle, my ipr stays around 34% until warm and the icp around 1200. Once it warms it cranks back fine, mainly the start up. Could this be a hpop? I replaced hg while back and new plugs, cooler, and stc fitting along with injectors.

Also motor seems louder than normal. Cant quite say what it is, but the longer cranks and noise are a concern. Thanks

Sent from my SM-S134DL using Tapatalk

Now i had the truck stumbled coming up a mountain, and a p2285 code. I went ahead and replaced the icp and pigtail. Cranking when cold takes a long crank to build icp, once it hits 500 its starts. So dont think its the sensor or pigtail. At 32 degrees cold idle, my ipr stays around 34% until warm and the icp around 1200. Once it warms it cranks back fine, mainly the start up. Could this be a hpop? I replaced hg while back and new plugs, cooler, and stc fitting along with injectors.

Also motor seems louder than normal. Cant quite say what it is, but the longer cranks and noise are a concern. Thanks

Sent from my SM-S134DL using Tapatalk