GRN250

Member

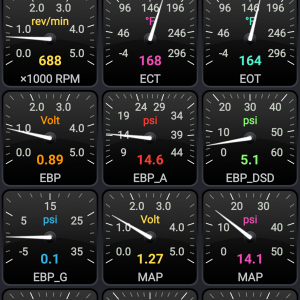

The FICM is modified and puts out a constant 52v. The ICP has 5.06v and the cam sensor has 3.08v. Haven't checked the IPR voltage yet. The truck is currently plugged in and warming the block. Will try to start it again tomorrow.Ok, so this seems like it’s an odd one.

What is fuel pressure while cranking? You said it dropped off after letting it set, but the pump should turn back on while cranking.

Also, what is FICM voltage, all 3 voltages, 2 should be battery voltage and one should be 48ish.

We’ve got icp, and it seems it’s trying to fire from the smoke out of the tail pipe. Are the glow plugs good? Do all injectors click good on a buzz test, none that don’t click or have a muted/dull click? Try plugging the truck in to get some heat in it if the block heater cord is installed, and see if that helps any. Leave it plugged in for 12 hours or so so it’s got plenty of time to get some heat in it.

The fuel pressure builds to 50+psi when the key is cycled but then falls off. I haven't been able to get a good video of the pressure when the key is held in the start position. The pressure does build up when the key is held in "start" but I can't say at what pressure exactly. Thanks for all the help.