Big Bore

Active member

I seriously could not believe my ears when the tech said that over the phone."Water caused the issue with the pump." While that certainly could happen to a pump in a properly setup AD I can not see it happening.

I really expected to see a lot of scoring on the gerotor parts. But of course I was under the impression there was no filtration before the pump per my conversation with the AD tech.You would also have likely seen the type of damage you see with pump cavitation.

It certainly makes more sense to me to filter the fuel before it gets to the pump.As has been said prior under vacuum its pulled thru the filter and perpulator perculator or whatever they call the vacuum stage I air removal part ( this is the part the FASS do not and can not have as its patented.)

AgreedFrom those pics after seeing a good number of burned out pumps as well as the few I personally had on my 7.3 until I switched to a Bosch it looks like a typical over-heating "thermal" failure.

I googled AD 100 blowing fuses and around the time this pump was purchased there was a rash of failures being talked about on the forums, and AD reps telling the owners the motor was bad and they would send out a new pump right away. They were failing within 10K miles. I'm not for sure but I'm pretty certain mine did too. In fact as I keep looking back and thinking about when I changed filters the first time, I think it was not working then because I remember thinking how quiet it was and I would constantly comment on how quiet the AD was. When I found the popped fuse after losing my Walbro, and replacing the fuse, the pump ran for about 2 seconds and I know I haven't heard that noise in a couple years/30K.That could have been from a jam but you not finding anything and the conditions of the parts rules that out most likely. My guesses are:

a defective motor or internal wiring

the following one happen way more IMO than people think:

improper voltage for the load making it to the pump.

It seems not very many people that are just basic back yard much have or use multimeter much. Its very possible you could have an issue in that area.

Smaller gauge wire , length of the wire run, and quality of wire and connectors effect how much of the full voltage reaches the pump. For every bit lost the amperage and thus thermal goes up to make up the loss of flow rate.

An improper or compromised ground can cause basically the same types of issues.

The alt itself not producing the voltage its suppose to.

Batteries are 1 year old Interstates holding good charge, alt putting out what it's supposed to, I check regularly on the AIC.

Wires are whatever is supplied by AD in the harness. I know it's an assumption but wouldn't AD have sized the wires appropriately for line drop? However along those lines, theres about two feet of wire and plastic loom coiled up and stuffed in front of the battery that I hadn't noticed till I began trouble shooting the prob. Just to reiterate, the truck came with the AD installed and around 7K on it IIRC.

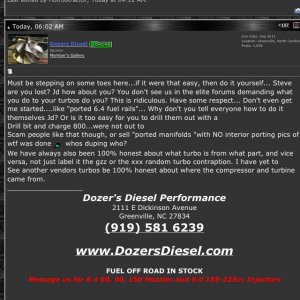

Those run around $190. AD will sell me a new pump with lifetime warranty for $175. I wish AD had treated me better on this because I'm willing to accept they got a bad batch of pumps from their supplier. However the way they've limited the lifetime warranty leaves me cold. Decisions.Personally if you like the idea of a lift pump to take the vacuum load off the HP pump a Carter 460o/4601 is diesel and marine rated.

With that or if you ever or anyone else puts in AD FASS or any pump in a lift pump position there is a extra step that will help prevent a lift pump failure taking out your more costly main pump. Plumb and wire in a fuel pressure sensor and gauge after the lift pump but before the HP pump. As long as you see positive pressure you know the HP pump has no load from its feed or input side its only load is from building pressure post pump which is what its does best and is built for. You could set it up with a trip light if you wanted where a small red or yellow light trips in the cab if you lose pressure so you know you have a issue.

IMO on things that can cause costly damage things like warning lights are hard to beat. You may not notice a dead fuel pressure reading driving but a red or yellow light tripping and lighting up will grab your attention fast. Hopefully save ruining a set of costly injectors barrels and plungers.

Good advice, a gauge would have saved me a lot of heartache.

Now that the pain of my ordeal is wearing off I'm really considering getting a 150 pump to replace the 100 and running it again with a gauge. By the time I go through all the trouble of setting up a water separator pre-pump I'll probably spend the cost of a AD pump and have more labor into it. It won't make me feel any better about AD and the warranty and my ordeal, but it will make me feel better about my Walbro.