Zeb

New member

I drilled and tapped a factory cap, so I’m seeing oil pressure in the filter housing.

The bearings are definitely softer than the roller or the needle bearings.

I think we need to look at this as not simply a pressure issue, but as a pressure/volume issue at the lifter.

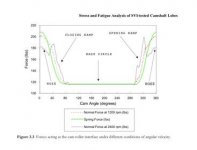

Geoff says if you look at the harmonics of a 6.0/6.4 cam lobe on a Cam Doctor, the lobe has a bump on it that shocks the lifter every time it comes around. He likens it to a tire hitting a pothole in the road.

When we think of the lifter getting shocked over, and over, and over again, combined with less than optimal oil pressure/quantity/quality when idled excessively, we get to see the cumalative effect of this.

This is why I think it is primarily a cam issue, but the cam isn’t the only issue.

I think the solution to this problem, for most cases is, Motorcraft lifters, Motorcraft oil filter and cap, and a decent oil, changed at the correct interval.

I tell guys if they’ll do this, they’ll wear the truck out before it needs lifters again!

The bearings are definitely softer than the roller or the needle bearings.

I think we need to look at this as not simply a pressure issue, but as a pressure/volume issue at the lifter.

Geoff says if you look at the harmonics of a 6.0/6.4 cam lobe on a Cam Doctor, the lobe has a bump on it that shocks the lifter every time it comes around. He likens it to a tire hitting a pothole in the road.

When we think of the lifter getting shocked over, and over, and over again, combined with less than optimal oil pressure/quantity/quality when idled excessively, we get to see the cumalative effect of this.

This is why I think it is primarily a cam issue, but the cam isn’t the only issue.

I think the solution to this problem, for most cases is, Motorcraft lifters, Motorcraft oil filter and cap, and a decent oil, changed at the correct interval.

I tell guys if they’ll do this, they’ll wear the truck out before it needs lifters again!

Last edited: