Strokinbronco

Member

- Joined

- Aug 12, 2018

- Messages

- 71

- Reaction score

- 4

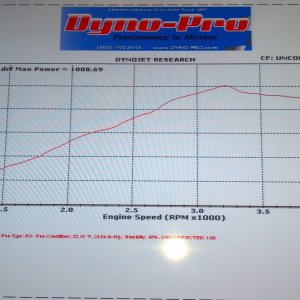

Okay guys here we go. I have a 1993 bronco with a 96' 7.3 running compounds, it's an s369 / gt5523 (88mm) with 400/200s for fuel. My issue is that I'm having a hard time spooling while daily driving, the setup won't even begin building boost until 2500rpm and the most boost I've gotten out of it is 60psi. That's less that what I've made with the s369 as a single. When I built the setup I made a bunch of changes to the truck, went from 38s to 35s but kept the 4.30 gears, also went from a low stall converter to a stock stall converter thinking it would help to light the chargers. Also the truck is relatively light at 5200lbs full of fuel. My intuition is telling me that the truck may be over-geared and not seeing enough load to spool the turbos but to be honest I'm kind of stuck. Any insight on the situation is appreciated and all opinions welcome, however I do ask that you refrain from asking "why put a 7.3 in a bronco, you can't tow with it" I did it cause I wanted to and that's all that matters.