isootmypants

New member

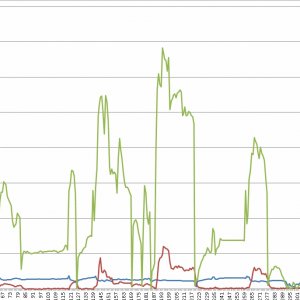

Was taking manifolds off to take out manifold gaskets and saw this h11 was gone. 3-4" down, snapped flush. 1" above deck height. Was thinking reverse drill bit, or maybe take another bolt with jb weld on bottom and stick it in hole let it cure the. Try backing it out. Was gonna take heater box out to get more room. Don't feel like pulling head. Any ideas?