Ok, that makes sense.

But......??

Is there really a need for the rest of us to use the tool then?

Sounds like if we just add a .045" shim that we'll get to where we're supposed to be.

It doesn't sound like the tool will actually read what each spring is set at.

Correct?

Or is there the possibility that each valve, retainer etc might be slightly different and that's why we need the tool, to actually read what each valve assembly etc is at and shim from there?

Thanks for all the great info!!

Jim~

as the valve (seats) wear...the valve recesses further & further into the head...thereby making the springs' installed height 'taller' than on a fresh head.

OEM spec (off the top of my head) for valve recession in the head is @ .040" +/-

we've had customers supply their own 'rebuilt' heads with new valves and the "works" with the valves recessed closer to .080...

machine shop work (& knowledge), mileage, as well as how clean the air was that went through the engine (dirtier air will increase valve seat wear, further recessing the valve)

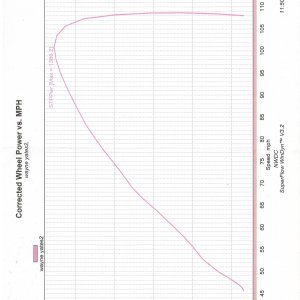

as a rough ballpark...trucks with 200k miles on them (typically) will need at least .030 shim to hit our desired installed height for the 910 springs (1.780") which equates to just under 125lbs of seat pressure.

springs installed @ 1.75" would have @ 134lbs of seat pressure.

getting much higher than @ 150lbs of seat pressure can cause the hydraulic lifter spring to collapse and start affecting actual valve lift...without doing things inside the lifter to combat this.

the factory specs are 71-79lbs of seat pressure @ 1.833" installed height, for both I&E valves.

so jusssst swapping in a set of 910's would take you from 71-79lbs to @ 99lbs with no shims.

the valve face diameter is 1.67"...

if you were running (for instance) 45lbs of boost...with stock springs...

you would have ~75lbs of force (45 x 1.67) acting on the valve to open it...without any help from the camshaft...not to mention backpressure acting upon the exh valve (which is typically higher than your boost pressure).

so...a spring is just a spring...sitting on a table..it has zero seat pressure LOL...

installing the spring

to do a specific task (high boost high rpm, etc) should be the concern. so I would recommend that you consider your boost & rpm when setting up your seat load.

...and for those that think if some more (pressure) is good...than a "lot" (more) must be better...just keep in mind that the higher the seat load...the more valve wear will occur from the harder 'hit' that the valve & seat absorbs with every opening & closing.