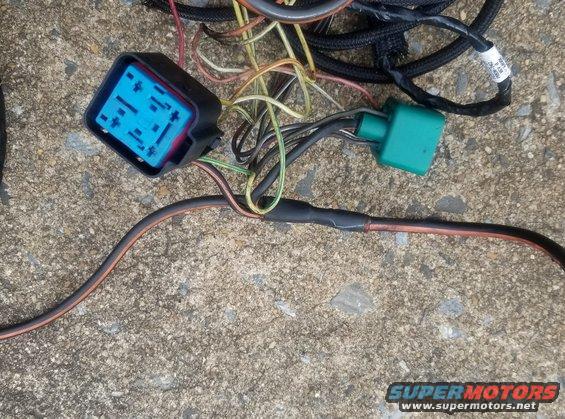

Finally decided to deal with old connectors, aged wires, and ratty looking tape & loom.

This one from the alternator has been bothering me since I got the truck. The green rot goes back several inches.

While I've been collecting pigtails, wire, and fresh bits & pieces I was doing a lot of searching for diagrams, pin-outs, and what not. Everywhere I've read has said this main wire from the alt cannot be replaced.

Turns out that is not at all true. Since I was replacing worn out GPCM connectors, I was going to have to deal with it anyway.

At least on my truck this is the only place in the wiring harness where this cable ties into anything. While I'm sure GPR truck are different, I can't imagine it being more complicated.

Once it was de-pinned from the connectors, it was completely free from the harness. Trading it for a run of 2ga and a mega fuse to replace the fuse links, and this was the easiest part. Still got ICP, IPR, & Valve cover connectors to do.

I was originally going to finish everything up in cheap techflex split braid I got from amazon. It will work for some of it, but I didn't pay attention to the heat rating and it does get melty in places where it contacts hot engine. Gonna have to rethink that.

This mess is a more time consuming job than I expected, but I should have it wrapped up later today and have more pics.

This one from the alternator has been bothering me since I got the truck. The green rot goes back several inches.

While I've been collecting pigtails, wire, and fresh bits & pieces I was doing a lot of searching for diagrams, pin-outs, and what not. Everywhere I've read has said this main wire from the alt cannot be replaced.

Turns out that is not at all true. Since I was replacing worn out GPCM connectors, I was going to have to deal with it anyway.

At least on my truck this is the only place in the wiring harness where this cable ties into anything. While I'm sure GPR truck are different, I can't imagine it being more complicated.

Once it was de-pinned from the connectors, it was completely free from the harness. Trading it for a run of 2ga and a mega fuse to replace the fuse links, and this was the easiest part. Still got ICP, IPR, & Valve cover connectors to do.

I was originally going to finish everything up in cheap techflex split braid I got from amazon. It will work for some of it, but I didn't pay attention to the heat rating and it does get melty in places where it contacts hot engine. Gonna have to rethink that.

This mess is a more time consuming job than I expected, but I should have it wrapped up later today and have more pics.

Last edited: