it won't with an 88+mm in front of it though....

that 71 is going to get laggier with another turbo

So by sticking something that is designed to capture energy retained in the exhaust (that would normally just escape to the atmosphere) and converting that energy to work on compressing the atmospheric air to help force feed his existing turbo (fancy way of saying that two turbos are simply going to net a higher system efficiency than one turbo will), the setup is going to get laggier?? How does that make any sense?? Don't get me wrong... I know that the S500 series turbos are HUGE and therefore are NOT going to be efficient at lower rpms. I get that and therefore, while I wouldn't expect necessarily that his spool up would be noticably faster, I would expect it to be about the same as it was and just don't get why it would be laggier. I mean unless the huge LP turbo isn't spinning at all when the truck is running (I can see that making it a restriction), then how is it going to be a restriction to the inlet of his turbo?? If there is that much friction in the BW journal bearing system, I guess I wouldn't be using that turbo for a LP turbo...

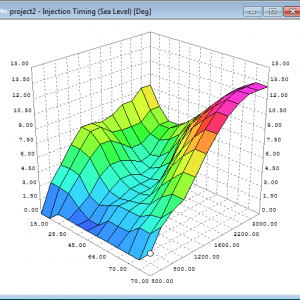

I've gotten data logs of using a 364 as a single turbo, and then when used with a S480 and while the same boost at say 2000 rpms or so was the same in both setups, it still started making boost at the same rpm it did as a single and when the turbo system (if you will) "lit off", it built boost at a faster rate than the 364 did as single...

I'm not here to argue. I just keep seeing this blanket statement thrown around here without any explanation as to why that is the case in a situation where it doesn't make sense as two turbos (pretty much regardless of size) are going to capture more energy from the exhaust than one turbo will, plain and simple.