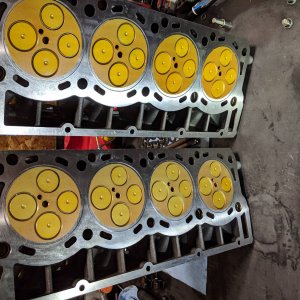

In my honest opinion if someone were to develop a set of true competition pistons, like the "Mahle's" Swamps offers, I called Ross they said they build an industrial like piston, with a larger bowl and lower "installed height" someone could build a truly "engineered pulling engine and compete.. This all goes back to the days of Big Cams and 3406b's, when I built a competition 3406b for a guy years back we used 14.2/1 one machined down pistons for an industrial engine, I used a dial indicator to determine the installed height to determine where the timing needed to be, needless to say we were running Sigma Plungers, yes Sigma does build plungers for B model pumps, just got have a hefty check book. If we used pistons with a lower compression ratio and lower installation height we could effectively lengthen the crank window to help with the fuel control and the ability to use it. If we look back in time NTC 400s used low low compression and NTC290s used high compression.. I may be full of b.s but when you construct an engine that makes 1250 hp and goes to 50 plus pulls and does pretty good, I can say this info was greatly learned from a few I talked to at Columbus diesel injection about compresson ratios, timing and the start of injection point. Imagine what a true cut piston, with a sooner (lower compression ratio/lower installed height) start of injection could do, then we could finally empty out all of our 450cc injectors efficiently.. I don't think anyone has been truly bold enough to try this other than people like Billy Zimmer or Ben Miller, but here again guys who were willing to put up serious coin and expierement.. Yeah it takes money, but if you look at Cummins guys, they are running a piston that resembles more of an industrial design, no quench area like a 7.3 piston.. I know this will prolly get ruled out on this forum, but this is my two cents from building a Hot stock 3406b..