were the two other trucks running vgt manifold turbos?

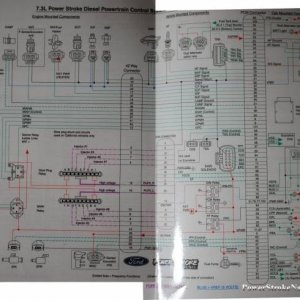

The problem that im seeing with the reference off of the exhaust side are the fact that the back pressure is always acting against the valve, therefore back pressure is always being "tuned in" to the gates, just because you are using boost referencing to control the gate, doesnt mean back pressure isnt doing some work on the gate.

Now since the vgt is thrown in the mix now everything becomes alot more sensitive, the vgt actuator reacts very quickly to changes in back pressure as needed. When you are using a reference off the exhaust side i feel that you are asking alot of everything to work in harmony and perfectly all the time.

Spartan tuning also uses pretty high back pressure tables compared to others. Generally from what i have found spartan will comand back pressure all the way up to 70psi absolute, where as alot of others will open the vanes as soon as back pressure basically reaches 40 psi, this is there way of staying on top of the back pressure to help keep it down on the top end. The problem with the spartan tuning is if the back pressure even drops a little the vanes will start to close right away thus making the surge.

IF your back pressure seams to be in check without the gate, then let it eat, no need for it anyway.

I would like to try one of these piston type gates, but i have no need for a gate right now so it would be pointless. But its definatly a cool option out there esp if the valves and seats can be swapped out