Proper way to get seating pressure all starts with the valve job.

Ensuring that all the valve recessions are the same is just one of many points.

The valve lengths, valve face, and margins are others.

Then, when your assembling the valves, to get the proper spring pressure, you install the valve, keeping that valve in that guide. Don't mix them up on assembly.

Install a retainer, and keepers. Then use a special tool to get the height from the spring seat, to the retainer...or, you can use a snap gauge, and measure it with calipers.

Document all the installed heights of all the valves.

Keep everything organized "to it's spot".

Throw away the stock springs, as they reach coil bind before you can get enough seat pressure to be of any use...get some beehive style springs.

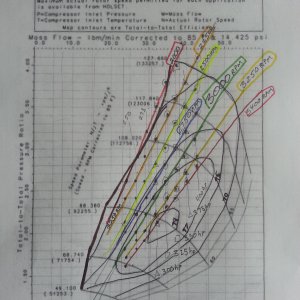

If you don't have a spring pressure tester, find a shop that does have one. But, the new springs will/should come with a card that states the spring pressure at such and such installed height.

Compare the height (measurement) you documented for each valve/retainer, and figure out how much shim you require to attain the seat pressure you desire.

For example, stock ford valves have between 70-85# of seating pressure, and something like 120# at max lift.

The springs I run have 120# of seating pressure, and around 250+# at max lift.

So no valve float on my setup.lol

Hope this helps.