I was wondering how much it would be to remove a 6 inch lift off of my truck. I don't have any of the stock parts. I guess what I am asking is if anyone has ever done it and was it hard or expensive to chase down the stock suspension parts. I drive a 2003 CCSB with 37 inc tires I am tired of jumping in and out of it. Possibly is anyone interested to trade stock suspension for my lift kit?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wanting to remove 6" lift

- Thread starter davidm781

- Start date

DieselMater86

New member

This dually or srw sounds like a 250.

Zmann

New member

- Joined

- Aug 5, 2011

- Messages

- 4,464

- Reaction score

- 0

i am going with a SRWccsb

really you might be best finding someone to trade with

otherwise you need shocks/pitman arm / front spring ubolts all around ( should do that anyway ) to name a few items off the top of my head

Gman239

New member

- Joined

- Mar 25, 2014

- Messages

- 1

- Reaction score

- 0

I am in the process of this myself and lemme tell ya it's about as expensive as it was to lift it in the first place.

***k trading someone. ***k chasing down the parts. Unless you have a boneyard with 8 coilsprung trucks at it locally, dont bother.

Go order new springs, blocks, ubolts, and if the shti is rusty hangers, shackles, and bolts. Word to the wise, remove the bed. You don't have room to run a ratchet or hammer and punch back there. Inspect your brake lines while there, especially with the bed off. Unhook the rear driveshaft at the pinion so it doesnt bind up on you locating the springs. You will need huuuuuuuge jackstand with high capacity to do this. You will need a good torch, 3/4 inch drive wrenches and sockets, and have liquid wrench there too. You'll need to reset your carrier bearing bed plate.

The front end on your truck is easy as hell.

Seriously though you need stands that will hold the truck and up about 45" from the ground to bottom of frame. You can set the axles on anything. Blocks, 2x4s, etc. I used 6x6 notched and nailed it to a longer 2x6 block. The axle isnt thaaat heavy. I picked mine up.

Remember: the pinion is going to find its center of gravity pdq when you unbolt it.

I just did this to my truck and its not fast or easy as far as processes go. Its way easier to lift a truck than what you want to do. That said if you really want to do it, be cautious and make sure you have all the parts BEFORE you start. Theres a good deal of shti you need that may have forgotten.

Go order new springs, blocks, ubolts, and if the shti is rusty hangers, shackles, and bolts. Word to the wise, remove the bed. You don't have room to run a ratchet or hammer and punch back there. Inspect your brake lines while there, especially with the bed off. Unhook the rear driveshaft at the pinion so it doesnt bind up on you locating the springs. You will need huuuuuuuge jackstand with high capacity to do this. You will need a good torch, 3/4 inch drive wrenches and sockets, and have liquid wrench there too. You'll need to reset your carrier bearing bed plate.

The front end on your truck is easy as hell.

Seriously though you need stands that will hold the truck and up about 45" from the ground to bottom of frame. You can set the axles on anything. Blocks, 2x4s, etc. I used 6x6 notched and nailed it to a longer 2x6 block. The axle isnt thaaat heavy. I picked mine up.

Remember: the pinion is going to find its center of gravity pdq when you unbolt it.

I just did this to my truck and its not fast or easy as far as processes go. Its way easier to lift a truck than what you want to do. That said if you really want to do it, be cautious and make sure you have all the parts BEFORE you start. Theres a good deal of shti you need that may have forgotten.

I am in the process of this myself and lemme tell ya it's about as expensive as it was to lift it in the first place.

Getting stupid shti like trackbar brackets and shock mounts will break you veeeery quickly.

Im about 5 grand in doing it all my self. The 6" lift cost 865 bucks when i did it. Just the new spring packs was 1500 dollars. Then i ordered, blocks, brakelines and some other shti from pmf, a site sponsor.

Fords rear blocks were cost prohibitive.

Just a heads up. Figure a lift and the odds n ends will run you 4500 dollars. Another 1500 to install. Id say you'll be about 5-6k to pay someone to do it. If you brought me all the parts, id have to get 3-4 grand, and probably more to do it. Lifted trucks are usually beat and dont want to come apart lol

Start soaking bolts and nuts 2 weeks prior to attempting. Wd40 has a penetrant out there now for disassembling rusty crap. It works great! Especially if you heat stuff first.

Start soaking bolts and nuts 2 weeks prior to attempting. Wd40 has a penetrant out there now for disassembling rusty crap. It works great! Especially if you heat stuff first.

cbf9703

New member

- Joined

- Mar 1, 2014

- Messages

- 5,596

- Reaction score

- 0

really you might be best finding someone to trade with

I agree.

Eh, I disagree. Been a part of swapping stock for 2-inch lift on two excursions (yes, labor on both trucks) then a year or so later swapped that 2 inch lift onto a truck, removed their 4.5 inch lift and put it on the Excursion. I haven't personally helped with, but have been around a couple suspension swaps on 6.0s as well.***k trading someone. ***k chasing down the parts. Unless you have a boneyard with 8 coilsprung trucks at it locally, dont bother.

Go order new springs, blocks, ubolts, and if the shti is rusty hangers, shackles, and bolts. Word to the wise, remove the bed. You don't have room to run a ratchet or hammer and punch back there. Inspect your brake lines while there, especially with the bed off. Unhook the rear driveshaft at the pinion so it doesnt bind up on you locating the springs. You will need huuuuuuuge jackstand with high capacity to do this. You will need a good torch, 3/4 inch drive wrenches and sockets, and have liquid wrench there too. You'll need to reset your carrier bearing bed plate.

The front end on your truck is easy as hell.

Seriously though you need stands that will hold the truck and up about 45" from the ground to bottom of frame. You can set the axles on anything. Blocks, 2x4s, etc. I used 6x6 notched and nailed it to a longer 2x6 block. The axle isnt thaaat heavy. I picked mine up.

Remember: the pinion is going to find its center of gravity pdq when you unbolt it.

I just did this to my truck and its not fast or easy as far as processes go. Its way easier to lift a truck than what you want to do. That said if you really want to do it, be cautious and make sure you have all the parts BEFORE you start. Theres a good deal of shti you need that may have forgotten.

Not being in the Rust Belt helps.

Getting stupid shti like trackbar brackets and shock mounts will break you veeeery quickly.

Im about 5 grand in doing it all my self. The 6" lift cost 865 bucks when i did it. Just the new spring packs was 1500 dollars. Then i ordered, blocks, brakelines and some other shti from pmf, a site sponsor.

Fords rear blocks were cost prohibitive.

My experiences have been totally different lol. Since I did swap out with people, I don't have stock suspension parts for the ex anymore, but I saved all my stock suspension for the Dodge in case I want to drop it back down.

And what lift did you do for 865? Dang! LOL

Sent from my XT1254 using Tapatalk

***k trading someone. ***k chasing down the parts. Unless you have a boneyard with 8 coilsprung trucks at it locally, dont bother.

Go order new springs, blocks, ubolts, and if the shti is rusty hangers, shackles, and bolts. Word to the wise, remove the bed. You don't have room to run a ratchet or hammer and punch back there. Inspect your brake lines while there, especially with the bed off. Unhook the rear driveshaft at the pinion so it doesnt bind up on you locating the springs. You will need huuuuuuuge jackstand with high capacity to do this. You will need a good torch, 3/4 inch drive wrenches and sockets, and have liquid wrench there too. You'll need to reset your carrier bearing bed plate.

The front end on your truck is easy as hell.

Seriously though you need stands that will hold the truck and up about 45" from the ground to bottom of frame. You can set the axles on anything. Blocks, 2x4s, etc. I used 6x6 notched and nailed it to a longer 2x6 block. The axle isnt thaaat heavy. I picked mine up.

Remember: the pinion is going to find its center of gravity pdq when you unbolt it.

I just did this to my truck and its not fast or easy as far as processes go. Its way easier to lift a truck than what you want to do. That said if you really want to do it, be cautious and make sure you have all the parts BEFORE you start. Theres a good deal of shti you need that may have forgotten.

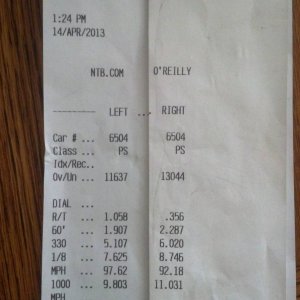

I bought these, best thing I ever bought. My safety is well worth the price.

http://m.oreillyauto.com/h5/r/oap/s...CD_-1_-1&mn=ACDelco&mc=ACD&pt=N0770&ppt=C0373

Sent from my iPhone using Tapatalk

I agree.

Eh, I disagree. Been a part of swapping stock for 2-inch lift on two excursions (yes, labor on both trucks) then a year or so later swapped that 2 inch lift onto a truck, removed their 4.5 inch lift and put it on the Excursion. I haven't personally helped with, but have been around a couple suspension swaps on 6.0s as well.

Not being in the Rust Belt helps.

My experiences have been totally different lol. Since I did swap out with people, I don't have stock suspension parts for the ex anymore, but I saved all my stock suspension for the Dodge in case I want to drop it back down.

And what lift did you do for 865? Dang! LOL

Sent from my XT1254 using Tapatalk

It was expensive in October of 2000....

After completely disassembling the truck, im sticking to I don't want someone elses beat up suspension pieces. I take care of my junk and I wouldnt give anyone these parts much less sell/trade.

I may clean up the overload pads and rear bracket/shackle, and rear spring top plate so someone who needs them can use them without coughing up 450$ for quad of the overloads.

Do as thou wilt but no way no how for this guy.

I bought these, best thing I ever bought. My safety is well worth the price.

http://m.oreillyauto.com/h5/r/oap/s...CD_-1_-1&mn=ACDelco&mc=ACD&pt=N0770&ppt=C0373

Sent from my iPhone using Tapatalk

They look safe but you need around 43" to allow enough room to "sag" the springs off a lifted truck.

I have some 6 tons. I have one 14 ton that opens to 65" because some dikkbag stole one.

Sounds like it is going to suck... I think I am better off just selling the truck and buying a 6.4 haha.. It looks like the lift I have on there is a trail master lift? Looks like blocks, leafs, shocks, u-bolts, pitman arm, stabilizer bars, and am I missing anything else?

Trailmaster made a 6" for super duties?

There is a trial master sticker on it so I am just assuming really. I know that I will have to take the shims out of the drive shaft to get it back to stock. Does it sound like I have most the parts listed.

I think so but you"ll think if domething you overlooked even if its only a few bolts. Dont be scared or discouraged just know you'll run into snags.

I hope you've been spraying that wd40 rust penetration formula or something similar on all the connections. It really makes all the difference. If you have 3/4" drive bars and sockets id recommend them simply because of the brute force they can take. Im so used to grabbing the 1/2" crap that i don't think and I broke 3 1/2 inch breaker bars. Hell i broke a 3/4 on the front rear spring bolt. Drivers side. Those ***kers are rusted/seized tight. Only two that gave me big trouble.

The one trackbar bolt was tight as shti. Oh! And you'll probably be cutting the ubolts off the rear. They get so seized up just from the extreme torque and the bolts have an unexplainable force in them from the stresses they see. Mine went flying when i torched through them.

If you really are a careful type of guy you could double check your ubolts and block height for your replacements. I did and it really saved me when reassembling.

I also had another idea that may be of use. If you dont have big, tall jackstands you coooould leave the tires on the truck and the you dont have to support the axle. But you still need to support whichever corner you're working on. Just an idea. You could do it corner by corner by cirner by corner.

I hope you've been spraying that wd40 rust penetration formula or something similar on all the connections. It really makes all the difference. If you have 3/4" drive bars and sockets id recommend them simply because of the brute force they can take. Im so used to grabbing the 1/2" crap that i don't think and I broke 3 1/2 inch breaker bars. Hell i broke a 3/4 on the front rear spring bolt. Drivers side. Those ***kers are rusted/seized tight. Only two that gave me big trouble.

The one trackbar bolt was tight as shti. Oh! And you'll probably be cutting the ubolts off the rear. They get so seized up just from the extreme torque and the bolts have an unexplainable force in them from the stresses they see. Mine went flying when i torched through them.

If you really are a careful type of guy you could double check your ubolts and block height for your replacements. I did and it really saved me when reassembling.

I also had another idea that may be of use. If you dont have big, tall jackstands you coooould leave the tires on the truck and the you dont have to support the axle. But you still need to support whichever corner you're working on. Just an idea. You could do it corner by corner by cirner by corner.

Thanks I appreciate it. I have most of the parts to do it but have the truck for sale. If it doesnt sell this week I will go ahead and install the stock suspension with a leveling kit and keep it like that until it sells. I appreciate the help and the tips.