Part 3: Tuning Maps, SOI, SOC, and other stuff.

Part 3: Tuning Maps, SOI, SOC, and other stuff.

Okay, so it took longer than I expected to get back to this and get it finished. There always seems to be something going on around here and there's just not enough hours in the day. :fustrate: But life goes on and sometimes you gotta say, "What the f***." For part 3 of our installment, we're going to cover SOI (Start of Injection), how it relates (or sometimes doesn't relate) to SOC (Start of Combustion), and how the PCM uses all the fancy tables at its disposal to generate the all-but-misunderstood SOI. So without further ado (da, ado-da), we bring you more of those pretty, colorful pictures that everyone loves!

As I mentioned earlier, when we started tuning these trucks back in the late '90s, we literally had no clue what we were changing. Everything was basically a best guess as we would change some values, dyno the truck, and then see what happened. Eventually we were able to identify tables that would relate to fueling, timing, and ICP, but still really didn't have any idea what those values actually were. We were changing HEX numbers by percentages and didn't have any actual engineering values to reference our changes. Pretty stone-age, eh? LOL

Fast forward a few years and we start to see the first of the graphical tuning applications for the Ford PCMs. Most of these were centered around the Mustang and F150 vehicles, but it offered us a bit of insight into how Ford used multiple table and temperature offsets to handle certain fueling and timing characteristics. Also around this time we were able to procure some documentation that helped break down some of the more useful functions and tables, and this information helped to set the base for much of the tuning software that is currently available for the Power Stroke. Coupling the acquired information with live tuning capability, we were able to see just how changing specific functions would affect fueling and timing, and also generated a better understanding of functional priority as well as functional accumulation. Understanding the order in which functions are processed as well as how the outputs are accumulated allows those who understand these processes to provide higher quality, better performing, and safer calibrations. Without that understanding, it is very easy to go out of range on Injection PW or SOI Timing and end up, in extreme cases, with a $10,000 paperweight.

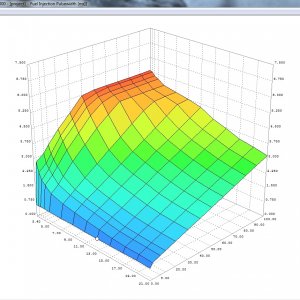

There is a LOT of data to consider when tuning, especially the effects that changing one function has on the output of another. For example, the Start of Injection Delay looks at ICP and EOT, as oil temp and injection pressure have a direct effect on WHEN the actual injection event occurs once the injector is turned on. This table is a crucial component of the SOI calculation and is often the most misunderstood. Since this table is dealing with an electro-mechanical delay, it is actually calculated in ms (milliseconds) versus the standard CAº (crank angle degrees). Because this is calculated in time, the actual CAº varies with RPM, roughly about 6º per ms per 1000 RPM. So, at 2000 RPM the offset is about 12º per ms and at 3000 RPM the offest is about 18º. The offset table considers ICP and EOT and provides this base output value upon which all other timing calculations are added. Here is what the SOI Offset table looks like:

Start of Injection Offset - Stock

(click on image to enlarge)

What is important to understand about this table is that this is quite often the table that many tuners adjust to control SOI Timing. Where this is a concern is that when tuning this table, you MUST take into consideration what your ACTUAL ICP is at or you can run into a severe problem. We've seen a number of tables like this:

Start of Injection Offset - Economy

(click on image to enlarge)

The problem with this situation is not necessarily that the electrical offset is excessive (it is a bit, and to be honest we've used tables like this in the past as well...), but that it scales down considerably as ICP decreases. The reason this is a problem is that with some tuning there maybe a loss of ICP due to excessive Inj. PW, worn injectors, weak HPOP, or bad IPR. If the vehicle is tuned for this condition and the timing is set accordingly, any change in ICP will yield a change in SOI. And to make matters worse, the problem is compounded by an even greater change in SOC as well. Consider this situation (and this is NOT an uncommon situation):

Under hard acceleration, a tuned truck is requesting a conservative 4ms of injection pulsewidth. Despite the fact that the ECM is requesting 3000 PSI (20.5 MPa) of ICP, the ICP starts to fall off and approaches somewhere in the area of 2400 PSI (16.5 MPa). This causes a shift in the SOI Offset table from 1.6 ms to 1.4 ms, or 1.2º degrees per 1000 RPM. Even at 3000 RPM, this only comes out to 3.6º difference which really isn't that big a deal. The problem is that the related loss in ICP produces a cooler, slower injection event and results in a later SOC event... Considerably greater than just the 3.6º lost from the SOI Offset shift. Now take that same vehicle and tune and change the HPOP (as is often advised by tuners to "resolve" the low ICP issue, even though the tuning is often at fault). Now you are able to maintain 3000 PSI ICP and your 3.6º of SOI is restored, along with a hotter, faster injection event. This results in an SOC that changes more than the 3.6º shift in SOI. In fact, CP (Cylinder Pressure) testing has shown that a 500 PSI change in ICP can result in 5º to 12º of change in SOC, and sometimes even more depending on the SOI point. Combined with the original 3.6º SOI shift, that anywhere from 8º to 15º of change in the combustion point, just by changing ICP 500-600 PSI.

This fact alone has caused more engine failures than any other condition, mechanical or tuning. Ask most people when their engines failed and they'll tell you, "It was just driving down the street. I wasn't even at half throttle." This is because in most of these situations, full throttle conditions actually resulted in a loss of ICP and ultimately a reduced SOI and SOC as well. The failures came under moderate driving conditions where ICP was high and SOI and SOC were much higher.

Now, the rest of the SOI tables are calculated in CAº so these are easier to understand and put a finger on. These values are calculated out and are cumulative against each other based on specific operational parameters. Some relate directly to EOT (Engine Oil Temp.) and RPM, other relate to MFD (Mass Fuel Desired) and RPM. All of these need to be addressed in order to produce calibrations that are responsive in all driving conditions and under all temperatures.

When considering SOI, it is very important to remember that SOI

DOES NOT DIRECTLY relate to SOC. A 3º change in SOI can often result in a 4º, 5º, or greater change in SOC depending on the crank angle, injection pressure, aircharge temperature, boost, block temperature, and other factors. This is why it is extremely important to have quality datalogs to validate all operational conditions and to ensure those conditions are stable within the confines of the tuning. If ICP is not stable, the tuning must be rectified to ensure that it is, otherwise the result could range anywhere from a poorly performing vehicle all the way to engine failure. If you cannot adequately anticipate the conditions, you cannot properly tune the vehicle.

These examples below are taken from a recently rebuilt 7.3L with little more than standard machine work, new stock pistons, a stock cam, stock heads, 250cc/200% injectors, and a GT38R turbo. This combination produced 543 HP at 85ºF and an impressive 566 HP at 55º F. Here are some screen shots of the tuning curves from the program as produced through

AnalyTune. Samples are taken at 190º EOT, at which the engine was dynoed at.

Injection Control Pressure

(click on image to enlarge)

Injection Pulsewidth

(click on image to enlarge)

Start of Injection Timing

(click on image to enlarge)

Keep in mind that these are "

DESIRED" values. While SOI and PWM values are consistent between desired and actual, ICP values may vary depending on the capability of the HPOP. It is extremely important to look at the generated values from the datalogs to ensure that the "DESIRED" values and the "ACTUAL" values correlate. In looking at the resulting datalog recorded during the run (below), you can see that not only was the ACTUAL ICP stable and comparable to the DESIRED ICP throughout the run, but even the recorded SOI is right in line with the anticipated SOI from the above graphs.

Datalog - 140x_stage_3_final.xls

Also keep in mind that this is done WITHOUT forcing a maximum SOI Limit like some other tuners do (usually around 35º BTC). This means that this vehicle will run just as well when cold as it does hot. Under normal circumstances, the ECM will advance timing considerably when cold. For example, at 50º F, the SOI Timing curve would look like this...

Start of Injection Timing @ 50º F

(click on image to enlarge)

This is the difference between the two files....

Start of Injection Timing @ 50º F vs. 190º F

(click on image to enlarge)

The SOI Timing difference is considerable, and clamping the SOI on vehicles that run in colder climates can translate into noticeable cold-start and cold running issues, excessive white smoke, and considerable loss of performance until the engine reaches normal operating temperature. These engines need advanced SOI Timing when cold to offset the low compression temps, cold air charge, cold fuel spray, and even the inherent injection delay cause by the increased viscosity of the cold oil. Obviously, the best approach is to let the PCM handle the SOI in the manner in which it was designed for the best drivability in all situations.

As we've already stated, SOC is not directly related to SOI. This is because the fuel spray relies on the temperature of the compressed air mass in order to ignite. Even a small change in crank angle can have a dramatic effect on the specific temperature of the air mass at the point of injection and can advance or retard the point of combustion. When you take into consideration factors such as block temperature, ambient temperature, aircharge temperature, boost, intercooler efficiency, fuel temperature, injection pressure, spray pattern, atomization, and other minor factors, it becomes a real challenge to identify any sort of SOC point... At least without appropriate CP testing equipment. It is in this that experience has as much to do with tuning as equipment. Historically, there have been a number of ways to approach tuning that vary from the scientific (Dataloggers, CP testers, and other diagnostic equipment) to the downright mystical "experienced tuner's ear". Over the years we've used a combination diagnostic equipment, experience, and just plain old common sense. With nearly 30 years in the automotive performance industry and 15 years in tuning the Ford Power Stroke, we've seen and tuned a wide variety of combinations and have accumulated a wealth of knowledge from every truck we've tuned. We've learned simple tricks to tuning just by using a boost and EGT gauge, and we've developed an ear for adjusting SOI based on the "sound" the engine makes under load. It is this experience that allows people to be able to push beyond normal thinking... To think outside the box and be able to look at a setup and help it to reach its maximum potential. Legends like Smokey Yunick used as much intuition in his approach to racing as he did tools and equipment. There is no question that there is an art to tuning, and some people just seem to "get it" better than others.

Anyway, that about sums up the topic of SOI and SOC. The relationship of Injection PW and ICP is a simple a mater of Fluid Dynamics and can already be easily calculated so there's not much reason for me to elaborate past the point that ICP is derived first and then the Injection PW is determined based on the amount of ICP produced. Pretty straightforward.

I hope this information is helpful. If anyone has any questions, I would be more than happy to answer them for you. Please post them here (do not PM) so that everyone can benefit.