The stock fuel system needs to be done regardless of anything even if you did not touch a injector or turbo. The stock fuel system is FUBAR for performance, durability and general efficiency of the engine performance as a whole.

AFter getting rid of the stock air box that would be the very next priority IMO if you are looking to have your injectors last, run smoothly, etc...

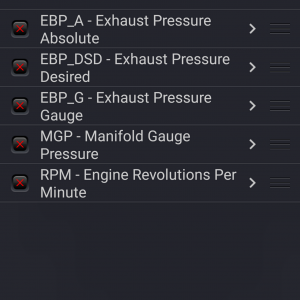

From there then Exhaust, Gauges, then chip tunes.

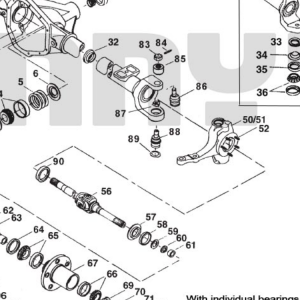

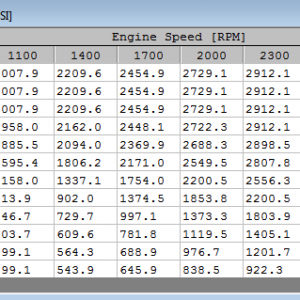

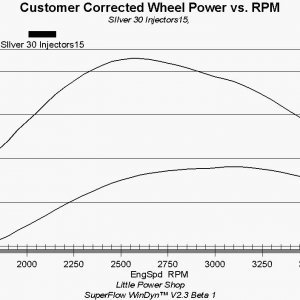

After that you can go with valve springs (measured and shimmed), push rods, studs, injectors, turbos etc. An upgrade from the single stock fuel pump as your fuel needs grow. IMHO, if doing this stuff in stages, the fuel system should go in prior and run with the stock pump until then with zero issues.

This of course is only my personal opinion but after a rather exhaustive review as of late.

I would also point out that personally I think a fuel pressure gauge in-cab is as critical possible more depending on usage than a dedicated trans temp. Fuel pumps go out, filters clog, fuses blow, engines over take pump capacity. Any of these happen which can still allow your engine to keep running and may go unnoticed for a time is enough to cook your injector's barrel and plunger. A $1000 bill that a simple fuel psi gauge would have prevented.

For me gauges would go: Turbo Boost, Turbo BP, EGT, Fuel pressure, Scan Gauge which will display any PCM hooked up sensor and one or 2 external IIRC. As well as warn of any codes, list, and clear them.