Power Hungry

Member

Hey all... I apologize for the long delay in getting these results out. Between getting ready for the Christmas holiday, working on the suspension for my 6.0L (which is another story in the works), and helping Corey get to her doctors appointments (why are ALL the good doctors in Atlanta, which is 40+ miles away???), I've just been short on time to get this information posted up. My apologies to all of you folks that have been patiently anticipating these results. So without further ado, let's get to business.

I'd like to start by saying MANY, MANY thanks to Jason Seay for the use of his truck as a test mule for a number of different 38R-based turbo combinations, including stock, a 1.15 A/R non-WG housing, the Bat-Mo-Wheel, and most recently the new 38R Wicked Wheel. This is not to mention a number of other parts we've tested and validated such as the CPR Fuel System, the Walbro replacement Fuel Pump, and the 250cc/200% Stage 3 injectors utilized in the current configuration. It is in-depth testing situations like this that help to provide an accurate analysis of what works, what doesn't, and where the best cost/benefit ratios are found. Jason, you are awesome!

Now on to the good stuff.

We had fairly recently tested this truck with a combination of different exhaust housings and turbo wheels to determine whether or not there was any benefit to making modifications to the factory Garrett 38R turbo. The conclusion we arrived at was that the stock 38R actually worked very well right out of the box providing the best combination of spool characteristics, peak boost output, and EGT control. Swapping to the larger 1.15 non-wastegated housing provided no benefit, actually causing a small drop in power and considerably more turbo lag. Swapping the compressor wheel had an even worse effect, losing nearly 4 pounds of boost and dropping power output nearly 50 HP. Not a positive outcome by any means. With all this in mind, we put the turbo back to a stock configuration (1.0 wastegated exhaust housing and stock compressor wheel) and validated that every thing was back to normal. With power levels back to where we started, we were ready to move forward.

When DieselSite released the new G2 Wicked Wheel for the stock turbo, the first thing I asked Bob (besides "Where's Mine?"...) was whether or not there was an option for the 38R. As it turns out, there was and I was handed both wheels to test. Since the transmission was still out of Jason's truck at the time, I test the WWG2 for the stock turbo first. The results of those test were, without a doubt, some of the most surprising I've experienced from the world of bolt-on performance parts. Given those results, I couldn't wait to test the new 38R wheel and see if the gains were going to be anywhere close to what we found on the stock 7.3L turbo, if there were any gains at all. I must say that I had some reservations as to whether we'd see any gains, given the losses we'd observed from the previous components we tested. We dug in, yanked the turbo again (for what feels like the 20th time), and after a small snag we finally had the new wheel installed and the turbo back on truck, ready for another round of dyno brutality.

Well, I'd have to say that I was a little disappointed that I didn't pick up almost 12 PSI like I did with the WWG2/Stock combination, but that's where my disappointment ends.

As usual, all dyno runs were performed in 3rd Gear with the Torque Converter locked and 8000 Lbs of load on the dyno. We performed a few dyno runs with the stock wheel/housing configuration and achieved a maximum boost of 34 PSI and a best HP of 555 @ 2680 RPM. Then we yanked the turbo and installed the new 38R Wicked Wheel. We made no changes whatsoever with the tuning... We strictly wanted this to be a bolt-on test. The results were immediate and impressive.

Dyno Run - GTP38R, 1.0 W/G housing, Stock compressor wheel

(All values rated at 3500 RPM)

Max Boost - 34 PSI

Max EBP - 52 PSI

Max EGT - 1400

Peak HP - 555 @ 2680 RPM

Peak TQ - 1116 @ 2625 RPM

Dyno Run - GTP38R, 1.0 W/G housing, WWG2 compressor wheel

(All values rated at 3500 RPM)

Max Boost - 40 PSI

Max EBP - 53 PSI

Max EGT - 1400

Peak HP - 572 @ 2660 RPM

Peak TQ - 1161 @ 2550 RPM

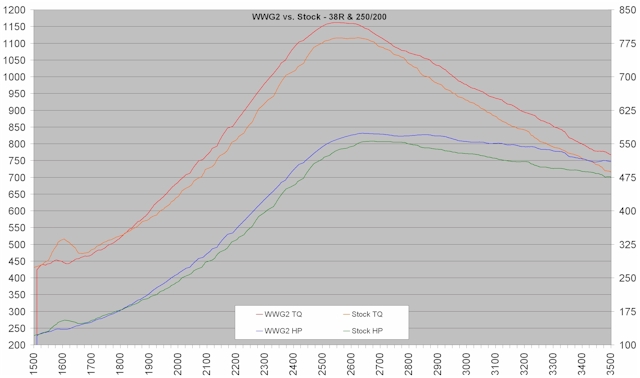

Dyno Plot - Stock Wheel vs. WWG2

(Click to enlarge)

As you can see by the dyno graphs, gains were observed across nearly the entire RPM range, with particularly sizable improvements in the 2000-2500 RPM and 2850+ RPM ranges. Visual observations included slightly faster spool times and reduced smoke output. Backpressure only increased by about 1 PSI, while Boost increased around 6 PSI. EGTs stayed about the same, peaking to 1400 Deg. at 3500 RPM. One interesting thing we did observe was that as the ambient temperature got hotter, the boost and low RPM power would rise more quickly, but there would be a slight loss in peak power. I suspect that heat soak in the block, intercooler, and ambient air would actually help provide a more efficient combustion and help spool the turbo faster in the lower RPM ranges, but end up with a minor loss in the upper RPM ranges caused by slightly hotter aircharge resulting from the increase in boost. However, since these losses were minimal and not in the "normal" operational RPM range for most people, I don't consider them to negatively reflect on the results.

As for the wheels themselves, here are the comparison images where you can clearly see the differences between each wheel.

Wheel Comparison (L to R - Stock Wheel, BWM, WWG2)

(Click to enlarge)

In regards to turbo surge, I didn't really experience any with the stock wheel/exhaust housing during dyno testing so I can't really say if this wheel would offer any improvement in such a scenario. It is generally accepted that a compressor wheel with single length blades may suffer from surge, but since the 38R comes pre-assembled with a ported compressor housing, we didn't see any indication of surge at all throughout a host of test RPM ranges. We also didn't see any significant benefit to running an aftermarket modified ported housing, but that may have simply been the nature of this particular vehicle configuration.

We plan to do a little more testing this weekend with some modest tuning changes to see just where we end up on the power scale, but overall I think the new wheel is a fine complement to what I thought was already a good turbocharger. Once I finish some injector testing on my personal 7.3L running the stock turbo/WWG2 combination, I'm seriously considering this as an airflow upgrade. After all, I'm all about relatively simple (and relatively inexpensive) bolt-on stuff. If I can run a stock turbo that moves air like a 38R (maybe that's a little optimistic, but we'll see ) or a 38R without having to switch to a T4-flanged setup (like a 4294, S472, or other setup), all the while saving a couple thousand bucks in the process, then it's a win-win situation! As we continue to push my little red truck, we'll keep everyone updated.

) or a 38R without having to switch to a T4-flanged setup (like a 4294, S472, or other setup), all the while saving a couple thousand bucks in the process, then it's a win-win situation! As we continue to push my little red truck, we'll keep everyone updated.

Enjoy.

I'd like to start by saying MANY, MANY thanks to Jason Seay for the use of his truck as a test mule for a number of different 38R-based turbo combinations, including stock, a 1.15 A/R non-WG housing, the Bat-Mo-Wheel, and most recently the new 38R Wicked Wheel. This is not to mention a number of other parts we've tested and validated such as the CPR Fuel System, the Walbro replacement Fuel Pump, and the 250cc/200% Stage 3 injectors utilized in the current configuration. It is in-depth testing situations like this that help to provide an accurate analysis of what works, what doesn't, and where the best cost/benefit ratios are found. Jason, you are awesome!

Now on to the good stuff.

We had fairly recently tested this truck with a combination of different exhaust housings and turbo wheels to determine whether or not there was any benefit to making modifications to the factory Garrett 38R turbo. The conclusion we arrived at was that the stock 38R actually worked very well right out of the box providing the best combination of spool characteristics, peak boost output, and EGT control. Swapping to the larger 1.15 non-wastegated housing provided no benefit, actually causing a small drop in power and considerably more turbo lag. Swapping the compressor wheel had an even worse effect, losing nearly 4 pounds of boost and dropping power output nearly 50 HP. Not a positive outcome by any means. With all this in mind, we put the turbo back to a stock configuration (1.0 wastegated exhaust housing and stock compressor wheel) and validated that every thing was back to normal. With power levels back to where we started, we were ready to move forward.

When DieselSite released the new G2 Wicked Wheel for the stock turbo, the first thing I asked Bob (besides "Where's Mine?"...) was whether or not there was an option for the 38R. As it turns out, there was and I was handed both wheels to test. Since the transmission was still out of Jason's truck at the time, I test the WWG2 for the stock turbo first. The results of those test were, without a doubt, some of the most surprising I've experienced from the world of bolt-on performance parts. Given those results, I couldn't wait to test the new 38R wheel and see if the gains were going to be anywhere close to what we found on the stock 7.3L turbo, if there were any gains at all. I must say that I had some reservations as to whether we'd see any gains, given the losses we'd observed from the previous components we tested. We dug in, yanked the turbo again (for what feels like the 20th time), and after a small snag we finally had the new wheel installed and the turbo back on truck, ready for another round of dyno brutality.

Well, I'd have to say that I was a little disappointed that I didn't pick up almost 12 PSI like I did with the WWG2/Stock combination, but that's where my disappointment ends.

As usual, all dyno runs were performed in 3rd Gear with the Torque Converter locked and 8000 Lbs of load on the dyno. We performed a few dyno runs with the stock wheel/housing configuration and achieved a maximum boost of 34 PSI and a best HP of 555 @ 2680 RPM. Then we yanked the turbo and installed the new 38R Wicked Wheel. We made no changes whatsoever with the tuning... We strictly wanted this to be a bolt-on test. The results were immediate and impressive.

Dyno Run - GTP38R, 1.0 W/G housing, Stock compressor wheel

(All values rated at 3500 RPM)

Max Boost - 34 PSI

Max EBP - 52 PSI

Max EGT - 1400

Peak HP - 555 @ 2680 RPM

Peak TQ - 1116 @ 2625 RPM

Dyno Run - GTP38R, 1.0 W/G housing, WWG2 compressor wheel

(All values rated at 3500 RPM)

Max Boost - 40 PSI

Max EBP - 53 PSI

Max EGT - 1400

Peak HP - 572 @ 2660 RPM

Peak TQ - 1161 @ 2550 RPM

Dyno Plot - Stock Wheel vs. WWG2

(Click to enlarge)

As you can see by the dyno graphs, gains were observed across nearly the entire RPM range, with particularly sizable improvements in the 2000-2500 RPM and 2850+ RPM ranges. Visual observations included slightly faster spool times and reduced smoke output. Backpressure only increased by about 1 PSI, while Boost increased around 6 PSI. EGTs stayed about the same, peaking to 1400 Deg. at 3500 RPM. One interesting thing we did observe was that as the ambient temperature got hotter, the boost and low RPM power would rise more quickly, but there would be a slight loss in peak power. I suspect that heat soak in the block, intercooler, and ambient air would actually help provide a more efficient combustion and help spool the turbo faster in the lower RPM ranges, but end up with a minor loss in the upper RPM ranges caused by slightly hotter aircharge resulting from the increase in boost. However, since these losses were minimal and not in the "normal" operational RPM range for most people, I don't consider them to negatively reflect on the results.

As for the wheels themselves, here are the comparison images where you can clearly see the differences between each wheel.

Wheel Comparison (L to R - Stock Wheel, BWM, WWG2)

(Click to enlarge)

In regards to turbo surge, I didn't really experience any with the stock wheel/exhaust housing during dyno testing so I can't really say if this wheel would offer any improvement in such a scenario. It is generally accepted that a compressor wheel with single length blades may suffer from surge, but since the 38R comes pre-assembled with a ported compressor housing, we didn't see any indication of surge at all throughout a host of test RPM ranges. We also didn't see any significant benefit to running an aftermarket modified ported housing, but that may have simply been the nature of this particular vehicle configuration.

We plan to do a little more testing this weekend with some modest tuning changes to see just where we end up on the power scale, but overall I think the new wheel is a fine complement to what I thought was already a good turbocharger. Once I finish some injector testing on my personal 7.3L running the stock turbo/WWG2 combination, I'm seriously considering this as an airflow upgrade. After all, I'm all about relatively simple (and relatively inexpensive) bolt-on stuff. If I can run a stock turbo that moves air like a 38R (maybe that's a little optimistic, but we'll see

Enjoy.