Powersmoker

New member

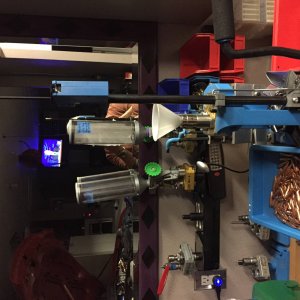

Finally got everything stitched up with the gt 4094 and the pt 106 now that I have most of the oil leaks tracked down and solved... Now I'm running into an excessively long crank to get the thing started it starts everytime but takes forever like ten seconds or so. The only thing I could correlate to this is how I pulled the feed off the top of the hpop reservoir? Any thoughts? Now I can also only build fifteen pounds of boost no pressure leaks pre turbine that are of consequence. Runs like a striped ass ape up to fifteen but then just stops, I do have it gated and I'm feeling that it is my problem how should I run it without Having to change the springs to what I want a way to fool it basically to only see the fifteen required to activate it when I want it to open up... Thanks for all the info in advance

Do you have any high pressure oil leaks? Even the smallest leak can cause a hard start like you described above. Which turbine wheel did you get on your Pt106? F Trim or G Trim? G trim is a big mo' fo'. I have the F trim on mine which is smaller and the compressor wheel I have is a 106mm clipped to a 101mm. What injectors are you running?

Feed your LP off a block oil port down by the pan rail on the passenger side. Free up the HPOP supply.

:whs: This would be a good idea.

I believe your problem is that you have boost to top and bottom so they cancel each other out. You are running on just the spring right now and that is what is keeping your boost down.

To be safe you could install a regulator between the boost reference and the top of the wastegate and slowly increase the pressure to see how the truck responds. That would prevent you from seeing crazy boost numbers. This would be with nothing attached to the bottom port.

:whs:

The way Vadar's Fury stated above is how I plumb my gates. Hook regulated boost/manifold pressure to the top port, then leave the bottom port open to atmosphere. The more regulated pressure you add to the top port, the more boost/drive you will make. Also, this setup is fail safe; If you rupture a hose for some reason (chit happens), boost pressure will drop not increase. One more thing I'd like to add, I would recommend you run a short piece of hose off the bottom port to keep contaminates out of the gate.

Let us know how it goes, I wouldn't be suprised if it works great. Once that atmospheric charger lites, hold the *** on! LOL

Last edited: