You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RCD Manifolds and Up Pipes

- Thread starter Dustball8504

- Start date

Mike@MPD

New member

100% i think

BogginF350

New member

Yes, 100's and they are coming out as soon as I have time.

Yes, 100's and they are coming out as soon as I have time.

Too much fuel?

madman1234509

New member

whos 100% are they?

Breaking Habits

New member

whos 100% are they?

Our 100's wayne. Josh is going to the same 60% you saw in my truck this weekend

BogginF350

New member

The 100% are just dirty and overkill. I like the truck the best with our 110tips.

madman1234509

New member

Nice, I was wondering if you had 100% tips. I looked on the site before and I thought I saw like 85% but not 100s. I really think Id like to try 100%s to start out and get some good tuning from you guys. I think they will work well with my 66/88 setup. The vids dzchey posted of how clean his was really got me leaning towards getting them and just dialing the fuel back as needed

BogginF350

New member

How did a single pump maintain 100%?

You have to tune the pulsewidth accordingly.

Paul@CP_Trucks

New member

Jared you have a message....

BogginF350

New member

Guys I wanted to put together a drawing for this but I have not had time to so I will share some info that we used to design and shape the manifold.

First I decided on 304 Stainless because it will essentially outlast you and I. Holds up very well to heat and keeps structural integrity under high heat/pressure (competition) use. Granted the price of stainless is much higher than the mild steel used in other units but, will never rust or corrode.

Secondly, sizing.. The volume is required to increase across the plane to net a increase in flow.

We addressed this by shaping the dies used to form the manifold based on cubic inches of internal volume ramping 100% at the introduction of the next port. In laymans terms the volume of the manifold is required to increase from port to port.

Here are the numbers:

Port 1 to start of port 2 - 8.33 in^3

Port 1 &2 to start of port 3 - 18.95 in^3

Port 1,2 &3 to start of port 4 - 31.62 in^3

Total volume to exhaust outlet flange - 38.37 in^3

Granted we were unable to make it perfect, but close enough. The reason for doing this is any unnecessary volume or a straight tube will effect spool up causing a laggy initial tip-in. On the other hand sizing the manifold to small will net little to no gains.

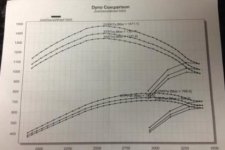

I have been running them on my truck and love them. Jareds truck put down 820 on rudys dyno with them. My daily driver did well on a superflow also netting well over 700rwhp. In my opinion, they work.

Add a set of the all new 304 Stainless up-pipes and you have a killer combination. These interchange back and fourth with stock parts, no mods are needed. Get them in hand and your ready to go!

First I decided on 304 Stainless because it will essentially outlast you and I. Holds up very well to heat and keeps structural integrity under high heat/pressure (competition) use. Granted the price of stainless is much higher than the mild steel used in other units but, will never rust or corrode.

Secondly, sizing.. The volume is required to increase across the plane to net a increase in flow.

We addressed this by shaping the dies used to form the manifold based on cubic inches of internal volume ramping 100% at the introduction of the next port. In laymans terms the volume of the manifold is required to increase from port to port.

Here are the numbers:

Port 1 to start of port 2 - 8.33 in^3

Port 1 &2 to start of port 3 - 18.95 in^3

Port 1,2 &3 to start of port 4 - 31.62 in^3

Total volume to exhaust outlet flange - 38.37 in^3

Granted we were unable to make it perfect, but close enough. The reason for doing this is any unnecessary volume or a straight tube will effect spool up causing a laggy initial tip-in. On the other hand sizing the manifold to small will net little to no gains.

I have been running them on my truck and love them. Jareds truck put down 820 on rudys dyno with them. My daily driver did well on a superflow also netting well over 700rwhp. In my opinion, they work.

Add a set of the all new 304 Stainless up-pipes and you have a killer combination. These interchange back and fourth with stock parts, no mods are needed. Get them in hand and your ready to go!

Attachments

BogginF350

New member

What I was looking for is Dustin's back to back testing he was going to do for you guys with the manifolds and up pipes. I would love to see just the swap and some numbers. If they do well and you should sell a TON of them because to date, nobody has any hard numbers of any gain with the manifolds for the 6.4L's

BogginF350

New member

I'm not the type to say you will have a 94rwhp increase. That is just ludicrous. But I will say my truck put down 730rwhp and Jared's identical build only netted 660rwhp on the same dyno. Same size tires, etc.

BogginF350

New member

This was before Jared swapped in the up-pipes and manifolds.

Breaking Habits

New member

What I was looking for is Dustin's back to back testing he was going to do for you guys with the manifolds and up pipes. I would love to see just the swap and some numbers. If they do well and you should sell a TON of them because to date, nobody has any hard numbers of any gain with the manifolds for the 6.4L's

Dustin is close I think. We're all just do damn busy lol

BFT

Moderator

Keep in mind these include ARP hardware, gaskets and stainless steel spacers.

Good sh!t right there

Dustball8504

New member

Dustin is close I think. We're all just do damn busy lol

You got that right, I've got a ton of different things on my plate all at once. I'll get these results, it's just taking me longer to get to this than I thought it would :doh: