gwunter

Active member

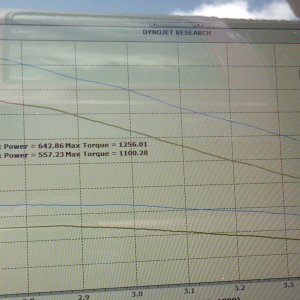

The old girl is still up and running. Actually better than ever. After the hx30 install it just didnt seem to run right for some reason. And i finally figured it out. It seemed to have a miss feeling during higher rpm and heavy load. I checked everything i could easily check and was stumped on it ever since the hx30 install. I never hooked up my ksb cold start mechanism on the injection pump, which was in turn advancing my injection timing 5*!! I never hooked it up because it always started so well. But i still cant explain why i didnt notice this miss type feeling with the h1c. But now it runs really well and pull in the upper rpms better. When i was testing it after the ksb hookup, the boost went to 45psi!! I was shocked it did tgat. The waste gate was closed off. Ill need to get my waste gate controlled better as i beliece 45psi is way off its map....and i dont want it to eat a compressor or chuck a turbine. I have also swapped out the luk clutch for a spec stage 3.5 clutch.there is a night and day difference in these clutches. Im very impressed with the clutch. Nice smooth action and good engagement. Ive also purchased ford factory service manuals to straighten out some creature comfort issues. Compounds, innercooler, and better amsoil oil filter setup are still to come. Im also going to install a air fuel ratio gauge to better tune the IP, pyro is installed and running and she never breaks 1200*f yet. Its got some smoke down low i would like to get rid of.