We did a little more 7.3 injector testing on Zac Bolen's truck... Results were a little surprising.

Truck is a 1999 F250 7.3 with irate t4 BASB turbo. 17 degree hpop. It is a dedicated tow rig that hauls heavy loads all over the country. Upwards of 30k lbs going up big grades in elevation.

He was running FF 160/100s, made good power, towed well, but struggled a little with egts while towing heavy and had an issue where it would run into icp/oil issues while towing really heavy at 3/4 throttle going up really long grades... we are pretty sure it was sucking the hpop oil reservoir dry. Very oil hungry injectors. Even on a 3.6ms tune ICP would drop to about 2700psi.

He decided to try some FF 205/30 hybrids injectors. Truck runs WAY cleaner, cooler, much easier to tow with, no more issues with sucking the oil reservoir dry. Very linear power band. EGTs are down 150-200 all across the board while towing and gained MPG. Holds a ROCK SOLID 3200icp at WOT. BUT... lost a little "oomph" down low under low throttle conditions, and top end power is down a little.

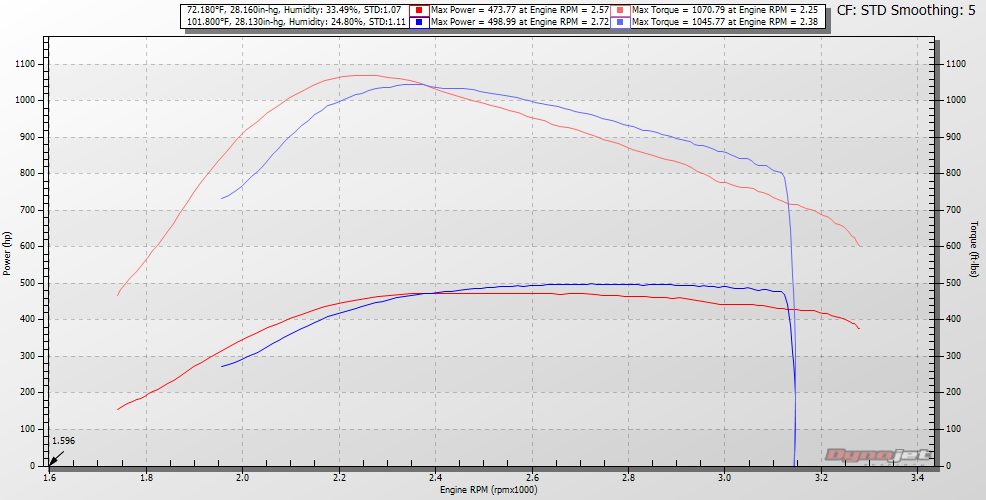

On the dyno the 205/30 brought on the power sooner, made more peak tq tq, ran cleaner, and made the same HP as the 160/100 up until 2500rpms where the power fell flat on the 205/30 and kept climbing with the 160/100... even though ICP was dropping like a rock with the 160/100s

So... why does it run so much cooler/cleaner and bring on the tq sooner? Smaller nozzles or hybrids? When we tested 180/30 vs 205/30, the 180/30 brought the power on sooner, not the hybrid. So I am going to say it is the smaller nozzle. Which makes sense because the smaller nozzle is known for better atomization and will spray the fuel farther into the stroke which increases tq.

Next on the list.... 238/80s... it will be interesting to see how they all compare.

Full Force Diesel Performance Inc.

Truck is a 1999 F250 7.3 with irate t4 BASB turbo. 17 degree hpop. It is a dedicated tow rig that hauls heavy loads all over the country. Upwards of 30k lbs going up big grades in elevation.

He was running FF 160/100s, made good power, towed well, but struggled a little with egts while towing heavy and had an issue where it would run into icp/oil issues while towing really heavy at 3/4 throttle going up really long grades... we are pretty sure it was sucking the hpop oil reservoir dry. Very oil hungry injectors. Even on a 3.6ms tune ICP would drop to about 2700psi.

He decided to try some FF 205/30 hybrids injectors. Truck runs WAY cleaner, cooler, much easier to tow with, no more issues with sucking the oil reservoir dry. Very linear power band. EGTs are down 150-200 all across the board while towing and gained MPG. Holds a ROCK SOLID 3200icp at WOT. BUT... lost a little "oomph" down low under low throttle conditions, and top end power is down a little.

On the dyno the 205/30 brought on the power sooner, made more peak tq tq, ran cleaner, and made the same HP as the 160/100 up until 2500rpms where the power fell flat on the 205/30 and kept climbing with the 160/100... even though ICP was dropping like a rock with the 160/100s

So... why does it run so much cooler/cleaner and bring on the tq sooner? Smaller nozzles or hybrids? When we tested 180/30 vs 205/30, the 180/30 brought the power on sooner, not the hybrid. So I am going to say it is the smaller nozzle. Which makes sense because the smaller nozzle is known for better atomization and will spray the fuel farther into the stroke which increases tq.

Next on the list.... 238/80s... it will be interesting to see how they all compare.

Full Force Diesel Performance Inc.

Last edited: