You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fuel system is done

- Thread starter Arisley

- Start date

03_PSD

Member

nice work Andy!

Arisley

Moderator

Thanks. I have no clue why, but it seems like my MPG have gone up a bit. Right now I have three filters in the system. But it must be running way more efficient. Seems like it starts a little quicker also.

Thanks. I have no clue why, but it seems like my MPG have gone up a bit. Right now I have three filters in the system. But it must be running way more efficient. Seems like it starts a little quicker also.

Its all in yer head ............ LOL !

TrailerHauler

Active member

Looks great Andy. Also some good info I wiring the pumps in.

Whenever I get around to doing my fuel system I plan on running the dual SD pumps with all the success that's been had so far.

I think I'll use the factory fuel pump harness to continue supplying power to one of the two pumps. And for the second pump bring power from the battery to a keyed hot, and switched relay. Or get real fancy and use a hobbs switch to control power to the second pump based on boost.

Why are most of you running a completely new fused circuit through a relay for both pumps instead of using the factory wiring for one, and putting a new circuit in for the second? (Hope that makes sense)

Whenever I get around to doing my fuel system I plan on running the dual SD pumps with all the success that's been had so far.

I think I'll use the factory fuel pump harness to continue supplying power to one of the two pumps. And for the second pump bring power from the battery to a keyed hot, and switched relay. Or get real fancy and use a hobbs switch to control power to the second pump based on boost.

Why are most of you running a completely new fused circuit through a relay for both pumps instead of using the factory wiring for one, and putting a new circuit in for the second? (Hope that makes sense)

Tree Trimmer

New member

- Joined

- May 22, 2011

- Messages

- 2,016

- Reaction score

- 0

its a completely new fused circuit for both. you split the one factory wire into two, to trip both relays, to give power to both the pumps. either both are on, or both are off.

still gives you the factory delay, meaning key on, engine off, the fuel pump doesnt run forever, just what ever the factory timer is.

any accident happening, say front end collision, that trips the "fuel pump shut off", will still kill both pumps, instead of just one.

im sure there are more, but you get the idea. it allows you to keep all the standard safety features of stock, just with two stock pumps.

still gives you the factory delay, meaning key on, engine off, the fuel pump doesnt run forever, just what ever the factory timer is.

any accident happening, say front end collision, that trips the "fuel pump shut off", will still kill both pumps, instead of just one.

im sure there are more, but you get the idea. it allows you to keep all the standard safety features of stock, just with two stock pumps.

TrailerHauler

Active member

its a completely new fused circuit for both. you split the one factory wire into two, to trip both relays, to give power to both the pumps. either both are on, or both are off.

still gives you the factory delay, meaning key on, engine off, the fuel pump doesnt run forever, just what ever the factory timer is.

any accident happening, say front end collision, that trips the "fuel pump shut off", will still kill both pumps, instead of just one.

im sure there are more, but you get the idea. it allows you to keep all the standard safety features of stock, just with two stock pumps.

I guess the point I was trying to make was poorly worded. I understand exactly how Andy did it, and there's nothing wrong with it.

What I'm wondering is why more people aren't using factory wiring for one pump and some type of switched/fused circuit for the second so that it only runs when needed and both aren't running all the time. I suppose what I'm getting at is IMO 90% of the time you won't need both pumps running to supply adequate fuel pressure.

But again, nothing wrong with running both pumps with relay's controlled by the factory pump wiring. That's how almost every setup I've seen has been done and its been successful so I guess there's no reason to stray from it. I think that I'm thinking out loud here. :redspotdance:

tgf

Member

Have you had a chance to take pictures of it mounted yet?

Arisley

Moderator

I guess the point I was trying to make was poorly worded. I understand exactly how Andy did it, and there's nothing wrong with it.

What I'm wondering is why more people aren't using factory wiring for one pump and some type of switched/fused circuit for the second so that it only runs when needed and both aren't running all the time. I suppose what I'm getting at is IMO 90% of the time you won't need both pumps running to supply adequate fuel pressure.

But again, nothing wrong with running both pumps with relay's controlled by the factory pump wiring. That's how almost every setup I've seen has been done and its been successful so I guess there's no reason to stray from it. I think that I'm thinking out loud here. :redspotdance:

It's just to simple to do it this way, and while your way has it's benefits, it is just to complicated to do, especially if you want to carry on with the KISS theory.

Have you had a chance to take pictures of it mounted yet?

To dark under there. I phone has no flash. Next time it is on a lift (OK, first time it is on a lift) I will take a pic.

Tree Trimmer

New member

- Joined

- May 22, 2011

- Messages

- 2,016

- Reaction score

- 0

I guess the point I was trying to make was poorly worded. I understand exactly how Andy did it, and there's nothing wrong with it.

What I'm wondering is why more people aren't using factory wiring for one pump and some type of switched/fused circuit for the second so that it only runs when needed and both aren't running all the time. I suppose what I'm getting at is IMO 90% of the time you won't need both pumps running to supply adequate fuel pressure.

But again, nothing wrong with running both pumps with relay's controlled by the factory pump wiring. That's how almost every setup I've seen has been done and its been successful so I guess there's no reason to stray from it. I think that I'm thinking out loud here. :redspotdance:

your thinking about someting like this.

one pump standard setup,

the other pump run off some sort of low pressure switch, when fuel psi drops to, lets say, 50 psi, the second pump turns on. builds pressure to, lets say 65psi, when it would need to trip a high pressure switch, or it would constantly be on like andys set up.

so now it trips that hp switch, and its shut off. but your still wot. so its dropping again, now we hit 50 psi, its back on.

thats alot of cycling that pump is doin, with some fast pressure fluctuations. your fuel pressure guage would twitch like a crack head coming down.

just normal driving, around town, your right, it would prolly rarely turn on. but when it did, it would cycle like a crack head, imo.

imo, constantly on, is much better for the pump, that all that cycling.

you could leave it with just a lp switch, so when it tripped it would stay on till you turn the key off, but unless you can maintain over your minimum fuel pressure, with the engine off, think it just sat in the garage over night, it will trip as soon as you turn the key on anyways

Last edited:

TrailerHauler

Active member

Well no, not necessarily a high and low pressure switch but more likely a simple on/off single pole single throw toggle switch that's operated by you. Essentially you would be doing exactly what Andy did, only with one pump instead of both, and controlling the relay with an on/off toggle switch as well as triggering the relay with the factory pump hot. So that you have the ability to turn one pump on and off at will.

Nothing wrong with doing it the way I'm trying to describe, and its no harder (except putting a switch in the cab). Just wondering if anyone's done it so they can control the second pump.

Nothing wrong with doing it the way I'm trying to describe, and its no harder (except putting a switch in the cab). Just wondering if anyone's done it so they can control the second pump.

Tree Trimmer

New member

- Joined

- May 22, 2011

- Messages

- 2,016

- Reaction score

- 0

i got ya now.

Arisley

Moderator

I do also. You would for sure want to put some one way valves in there to stop backflow.

TrailerHauler

Active member

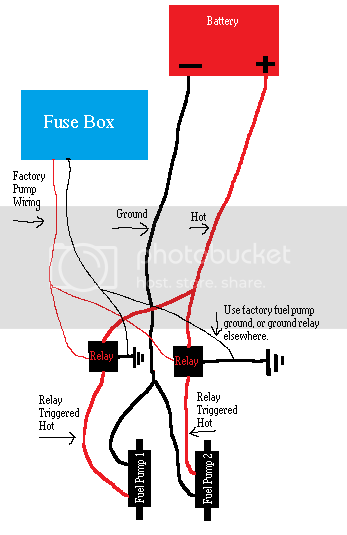

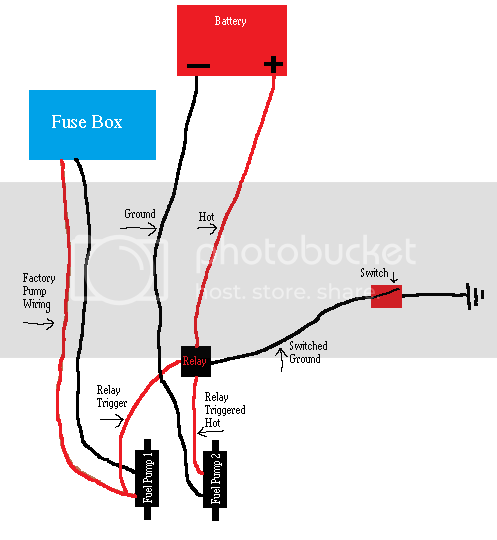

Here's some crappy photoshop drawings to better illustrate how the pumps can be wired in case anyone looking for a visual aid comes upon this thread.

Feel free to point out any flaws, or anything I missed.

Andy's way

Another option

Feel free to point out any flaws, or anything I missed.

Andy's way

Another option

TrailerHauler

Active member

I do also. You would for sure want to put some one way valves in there to stop backflow.

I think it may have been Marty, or someone else that found out fuel will not flow in the opposite direction through a stock SD pump, if I remember correctly. So check valves are not necessary.

Arisley

Moderator

Cool, did not know that. Thanks.

It will only not flow backward thru the stock pumps as long as you leave the OEM outlet fitting on the port. The check ball is in there. If you remove that to install a fitting with a JIC/an fitting to attach a hose end rather than using a crappy worm clamp you will loose the check valve.

Arisley

Moderator

I should be good to go then, I have two crappy worm clamps on each one.