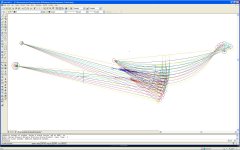

The point of the traction bars is to keep the pinion aligned with tail shaft (for one piece driveshafts) or aligned with the front driveshaft on twp piece setups. The nature of a leaf spring is the axle travel path is not an arc pivoting on the hanger, but a polyarc with the virtual pivot location constantly moving in space. To deal with this, the driveshaft has a slip joint that allows the driveshaft to shorten or lengthen as the axle goes through its convoluted travel path. I farted around with CAD a while ago to figure out where the pivot point would be and though it varied depending on what part of the suspension cycle the axle was on, bar length would need to be approximately 12' long, with the pivot point moving 1/2" in its spacial plane.

So why does bar length vary? Mounting options play a role in how long a bar can be. The longer the bar, the closer to the virtual pivot it will be. Depending on the mounting design of the bars, a long bar can have some flex to deal with the shortening virtual length.

As to the question of the spring determining the length of the bars....the shackle length affects changes to the virtual pivot location as much as the overall length of the spring. Regardless of the spring lenth, there is no practical way to to mount the ideal length bar as it would be somewhere near the front axle.