Ok, here's the latest and greatest. Not much. But our shed is just about finished, going to put a temporary work bench up so i can strip truck and motors down tomorrow and have something to work on.

Im going to do a minimun build on the motor i got from RCH on here. Reason, im sick of not having my truck, plain and simple. I am going to buy new pistons and send the connecting rods out to get treated and checked. Doing the min because of time and money right now. Getting the truck back on the road and paying it off before i do the crazy build. Just tired of bumming rides and not being able to find a decent vehicle for cheap without having to dump money into it as well.

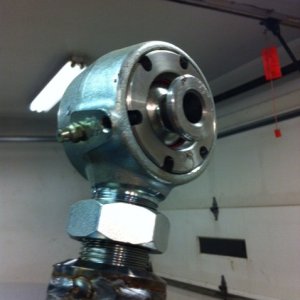

The blown motor is getting torn down and reusing everything.. studs, valve springs, push rods, up pipes and so on. The other motor i purchased off of RCH looks b e a utiful. So im going to clean it up, paint it and stick everything on it.

Quick question, since im putting new pistons in it due to low compression in a few cylinders, which head gaskets should i use. If stock is fine then thats what I will use. And do i still need machine work if im taking the heads off. The same heads are going back on the motor they came off, im not mix matching unless they are really messed up.

I dont want to dump aton of money into this motor for multiple reasons, some already mentioned. Main reason for new pistons 1. have to fix compression issues and 2. want coated pistons with bowl lip removed. I was going to try doing some port and polish work myself on the heads. Any one have tips on what to use or how to's.

Lastly to those who cant ever understand which route im going since my a.d.d always kicks in, I am doing this for already said reasons and my main worry is paying truck off rest of way and getting a bts, then and only then i am building a motor all out. Sorry for the confusion everyone but hope i cleared up some of it for you. Best part about doing it this way tho, is i get to have tunes that dont cater to PMR"s due to a huge turbo and bigger injectors.