First off let me state that my truck may be a unicorn because of the head porting and the cam, but has anybody else compared the 64.5 and 69mm versions? I didn't get a chance to dyno them back to back but the 64.5 makes 3-4 lbs more boost below 3000 rpms, then starts to taper off because I guess it is out of compressor or drive pressure is getting way out of line. I'm running 238-80s with the .9 exhaust housing. Spools great with the 64.5, and not so much with the 69mm....

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Turbo Findings SX-E 364.5 vs 369

- Thread starter Gearhead

- Start date

cwilson1539

New member

- Joined

- Mar 11, 2015

- Messages

- 10

- Reaction score

- 0

@KCTurbos

He did some testing on both, of course that was on the 6.0

He did some testing on both, of course that was on the 6.0

Last edited:

I have the 369 1.0. Once I pulled some timing it spools pretty fast. The tune I was originally running had too much timing advanced to where the turbo would not spool at all. Before that I just had the completely stock Obs turbo EBPV and all with a blown doughnut on the pipes and a blown spider oring and the same tune would still spool that turbo to 30 or so psi. I have sticks somewhere in the 350cc range 200s with fueling pulled way back. I am only running a mechanical fuel pump.

Last edited:

ruffneck7.3

Member

- Joined

- Jul 4, 2013

- Messages

- 108

- Reaction score

- 0

I'm very interested in hearing results of this as I'm considering both of those turbos and injectors of that size for my truck

Countrycar

New member

:

:rockon:I'd sure love to see KCTurbos new BB turbo that he's putting out. It was supposed to be out by now, but I haven't heard anything else about it lately. A bolt in version of an sxe369-BB Turbo. Should spool up great, as well as outflow a 38r. On your setup, that would just flat out kick butt. Maybe you can reach out to him and see if he'll hook you up with one. He should have beta testers by now as well.

:rockon:I'd sure love to see KCTurbos new BB turbo that he's putting out. It was supposed to be out by now, but I haven't heard anything else about it lately. A bolt in version of an sxe369-BB Turbo. Should spool up great, as well as outflow a 38r. On your setup, that would just flat out kick butt. Maybe you can reach out to him and see if he'll hook you up with one. He should have beta testers by now as well.

Hey Matt, I think you might actually be the only one that's had the opportunity to try both Turbo's back to back. Superpsd runs an sxe369 but he doesn't count, he runs a Super charger in front of his.First off let me state that my truck may be a unicorn because of the head porting and the cam, but has anybody else compared the 64.5 and 69mm versions? I didn't get a chance to dyno them back to back but the 64.5 makes 3-4 lbs more boost below 3000 rpms, then starts to taper off because I guess it is out of compressor or drive pressure is getting way out of line. I'm running 238-80s with the .9 exhaust housing. Spools great with the 64.5, and not so much with the 69mm....

Last edited:

hucorey

Member

I should be getting my new KC fairly soon.

Sent from my SM-G900V using Tapatalk

Sent from my SM-G900V using Tapatalk

Countrycar

New member

It should work nicely with your setup. Can't wait to hear how it performs.

ja_cain

Active member

- Joined

- Aug 10, 2013

- Messages

- 4,597

- Reaction score

- 2

I should be getting my new KC fairly soon.

Sent from my SM-G900V using Tapatalk

I'm waiting patiently too.

Btw, I will be reaching out to you once I get a few things out of the way. I want to send this SRP to you if you are cool with it?

I figure an srp and some 80% or 100% nozzle'd injectors would go well with this new turbo offering.

:

Hey Matt, I think you might actually be the only one that's had the opportunity to try both Turbo's back to back. Superpsd runs an sxe369 but he doesn't count, he runs a Super charger in front of his.:rockon:I'd sure love to see KCTurbos new BB turbo that he's putting out. It was supposed to be out by now, but I haven't heard anything else about it lately. A bolt in version of an sxe369-BB Turbo. Should spool up great, as well as outflow a 38r. On your setup, that would just flat out kick butt. Maybe you can reach out to him and see if he'll hook you up with one. He should have beta testers by now as well.

Is true my setup is not easily comparable. At full tilt however the blower is no longer being used. I pulled the completely stock turbo with blown up pipe and it had no spooling issues and the 369 with 1.0 with no other changes would not spool up at all without any other changes. So I was pointing out that it's laggier than a stock "laggy" Obs turbo stock 1.10 housing and EBPV intact. I had to reduce timing which increased egts to feed the 369 some hot air to get it to spool up. I could go with the .91 housing to reduce spool time but I want to keep back pressure low (stock valve springs)

Last edited:

mikeeg02

New member

I haven't run the 364.5 or the 369, but I'm right in the middle running the 366sxe with a 1.0 housing, with your tuning and it's spot on and perfect. 238/100s feeding it. Mines the standard shift 01 you guys were working on the all out file for. At 3.2ms or pulse width on the big end, I cannot no matter how hard I try, exceed 1200* (and I've tried) spools up very well. And is 1:1 up to 40-42 psi.

As you probably know, the 369 only has a larger inducer on the comp wheel. All other dimensions are the same.

As you probably know, the 369 only has a larger inducer on the comp wheel. All other dimensions are the same.

Countrycar

New member

Hell of a setup my friend.Is true my setup is not easily comparable. At full tilt however the blower is no longer being used. I pulled the completely stock turbo with blown up pipe and it had no spooling issues and the 369 with 1.0 with no other changes would not spool up at all without any other changes. So I was pointing out that it's laggier than a stock "laggy" Obs turbo stock 1.10 housing and EBPV intact. I had to reduce timing which increased egts to feed the 369 some hot air to get it to spool up. I could go with the .91 housing to reduce spool time but I want to keep back pressure low (stock valve springs)

Hell of a setup my friend.

It's work in progress. I'll be hopefully moving on to adding an SD pump to the fuel system as a booster pump and using a PLC that I have on the way to control it. I replaced the leaking mechanical fuel pump with a new one and pressure is better and it is even running smoother that it had before.

Countrycar

New member

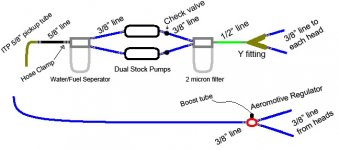

I rememeber you saying that you were running out of fuel on the top end. Hopefully this will get yah where you need. I run a Fass system, and I've never seen the fuel Pressure needle budge. It is a little loud, but it does the job. Is this kinda what your looking at doing?It's work in progress. I'll be hopefully moving on to adding an SD pump to the fuel system as a booster pump and using a PLC that I have on the way to control it. I replaced the leaking mechanical fuel pump with a new one and pressure is better and it is even running smoother that it had before.

Attachments

That is the dual SD pump setup. I could easily set mine up that way. I have two new SD pumps sitting on the shelf. I am actually keeping the mechanical fuel pump as I have the system now. I already run a aftermarket filter and aeromotive regulator. I will be adding a feed from the tanks with one SD pump that will feed the banjo fitting along with the mechanical pump. I plan to use the PLC I ordered to control the SD pump on an off as needed. Basically an on demand fuel booster pump. The PLC also has wireless capability and I will be using an app on one of my Android devices as a HMI. Using the PLC I can also setup an alarm system to warn me if fuel pressure drops below n optimal point. Most of the time the electric pump will not be used. I just put in a new healthy mech pump.

Last edited:

Countrycar

New member

Nice, this should should the beast. Now you'll be able to see what it can do. Let me know how it works once you get it all dialed in. One of these day I'm gonna make a trip up there to visit yah. We can drink a beer and share some stories. Nice drive too. I love road trips.That is the dual SD pump setup. I could easily set mine up that way. I have two new SD pumps sitting on the shelf. I am actually keeping the mechanical fuel pump as I have the system now. I already run a aftermarket filter and aeromotive regulator. I will be adding a feed from the tanks with one SD pump that will feed the banjo fitting along with the mechanical pump. I plan to use the PLC I ordered to control the SD pump on an off as needed. Basically an on demand fuel booster pump. The PLC also has wireless capability and I will be using an app on one of my Android devices as a HMI. Using the PLC I can also setup an alarm system to warn me if fuel pressure drops below n optimal point. Most of the time the electric pump will not be used. I just put in a new healthy mech pump.

Countrycar

New member

Sure. Just let me know ahead of time. :toast: I was planning to take a road trip down to Cali this summer.

If you make it here before I get there, I'll hit up Brad too and we'll come meet yah somewhere.

The Brad

New member

If you make it here before I get there, I'll hit up Brad too and we'll come meet yah somewhere.

Definitely!