Peroni

Member

I can't take credit for coming up with this mod. In my search I found discussions going back to at least 2004 about replacing the stock C2 pump with a C3 pump using all Ford parts.

Any OBS owner knows the stock C2 is lacking in both flow and pressure and that most "re-manufactured" pumps are about as bad as the worn out one it was to replace. Performance suffers further when more demands are made of the pump like large tires or adding hydroboost.

However Ford was equipping the 7.3 vans with an improved C3 style pump. These parts will bolt right up to the OBS motor with no mods. One can use the van pump but a 6.0 pump will also bolt right in. The only obstacle to overcome is that the new pump requires a remote reservoir.

I'll tackle the reservoir first, this was the biggest challenge for me with this project due to lack of available space. I already have my CCV filter mounted on the IDM. The ISSPRO Performax brain box is tucked into the corner on the firewall. The IC pipe and AC lines clutter up the space next to the radiator. I had one sliver of space left right between the hydroboost unit and the Isspro box. Not liking any of the commercially available remote reservoirs I set out to make my own. After a lot of thought and reading discussions on reservoir design I came up with something about the size of a large paint spray can. It holds just over a quart of fluid which should be plenty adequate. Top and bottom caps are sealed with an oring plus I put another oring seal for the cap, added a vent, dipstick and baffle plate to prevent fluid from sloshing into the vent. Being a machinist and engineer plus having my own shop really helped here.

Next the firewall is marked for the reservoir location. I did have to unbolt the booster to gain access for drilling the holes but there was enough room to kind of push things aside without removing the master cylinder or brake lines. I selected some stainless steel rivet nuts, drilling them reaming the holes to the specified size.

I did end up having to space the reservoir out from the firewall and additional 1/8". I did this with some washers but plan to make a proper spacer plate when time permits.

The engraved dipstick. I calculated the fluid expansion in Solidworks and it actually came out pretty accurate.

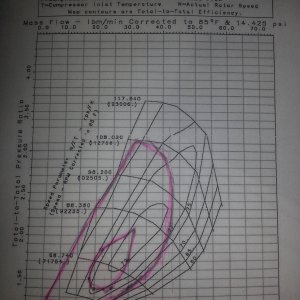

With that out of the way I moved on to the pump itself. I used a NOS 2005 6.0 pump that popped up on Ebay for less than most part store remans. It is marked HBD-MX and from what I could find published it puts out 2.8-3.2gpm with a min/max relief of 1750 and 1850psi.

The stock HBC-JX pump flows 1.4gpm with relief setting of 1400 and 1530psi. The HBC-JY which was used on the SD trucks with hydroboost flows 1.5gpm with a 1450 and 1530psi relief.

So the 6.0 pump put out a nice bump in both flow rate and pressure.

The pump bracket is from an Ebay auto salvage seller. New brackets are also available if you want to spend the money. This is a direct bolt in for the stock OBS part. Your AC compressor and vacuum pump will bolt right up. The orientation of the vacuum pump is now horizontal instead of being tilted up slightly but its actual position on the engine is the same. Same goes for the pump itself which means you do not need to get a longer/shorter belt.

Now for the pulley, this might be the hardest part to get hold of. You need to use the van pulley, no way around this that I'm aware of. The C3 pump shaft is slightly smaller than the C2 so your stock pulley will not fit. The van one is identical to the stock pulley except for the smaller bore. Aftermarket pulleys are not available for the van so get scrounging in the salvage yards. Ebay again came to my rescue with a NOS pulley which is pictured on the left here.

Install is straight forward, just swap one bracket assembly for the other.

The hoses are pretty straight forward too. I used a good quality 3/8 power steering hose to go between the reservoir and hydroboost unit as well as the return line coming off my fluid cooler.

The pressure hose I modified from the stock hydroboost line. I cut off the metal line right where it turns to rubber on the booster end, flared it and used a 3/8 jic coupler. The pump takes a metric ORB fitting, M16 x 1.5 to 3/8 jic. At the time I could not find a supplier who had a 90° fitting in stock so I used a straight one. Thought I could use a hydraulic hose with a 90° elbow on one end but the steering gear lines were in the way. So I used a piece of heavy wall tubing and bent it into a U then bent one leg over at 90° and angled it to line up with the hydraulic hose that connects up to the piece coming off the booster. In the future I plan to neaten this up now that I have a 90° metric to jic fitting. I can dispense with the lower section of bent tubing and just get a longer hydraulic hose.

After double checking everything I filled the system with LE 7500 power fluid and purged the air per Ford's procedure. Now I never really had any issues with my HBC-JY pump which I installed at the same time as my hydroboost unit. However I can say there is a marked improvement with both steering and braking with this new pump! It take less braking effort to stop the truck and steering feels lighter and more positive than before esp at idle and low speeds. No issues noted at all when using brakes and steering at the same time. I do have a spare hydrobooster unit here and am thinking about consulting with VANCO to see if having it ported will yield even better results.

Any OBS owner knows the stock C2 is lacking in both flow and pressure and that most "re-manufactured" pumps are about as bad as the worn out one it was to replace. Performance suffers further when more demands are made of the pump like large tires or adding hydroboost.

However Ford was equipping the 7.3 vans with an improved C3 style pump. These parts will bolt right up to the OBS motor with no mods. One can use the van pump but a 6.0 pump will also bolt right in. The only obstacle to overcome is that the new pump requires a remote reservoir.

I'll tackle the reservoir first, this was the biggest challenge for me with this project due to lack of available space. I already have my CCV filter mounted on the IDM. The ISSPRO Performax brain box is tucked into the corner on the firewall. The IC pipe and AC lines clutter up the space next to the radiator. I had one sliver of space left right between the hydroboost unit and the Isspro box. Not liking any of the commercially available remote reservoirs I set out to make my own. After a lot of thought and reading discussions on reservoir design I came up with something about the size of a large paint spray can. It holds just over a quart of fluid which should be plenty adequate. Top and bottom caps are sealed with an oring plus I put another oring seal for the cap, added a vent, dipstick and baffle plate to prevent fluid from sloshing into the vent. Being a machinist and engineer plus having my own shop really helped here.

Next the firewall is marked for the reservoir location. I did have to unbolt the booster to gain access for drilling the holes but there was enough room to kind of push things aside without removing the master cylinder or brake lines. I selected some stainless steel rivet nuts, drilling them reaming the holes to the specified size.

I did end up having to space the reservoir out from the firewall and additional 1/8". I did this with some washers but plan to make a proper spacer plate when time permits.

The engraved dipstick. I calculated the fluid expansion in Solidworks and it actually came out pretty accurate.

With that out of the way I moved on to the pump itself. I used a NOS 2005 6.0 pump that popped up on Ebay for less than most part store remans. It is marked HBD-MX and from what I could find published it puts out 2.8-3.2gpm with a min/max relief of 1750 and 1850psi.

The stock HBC-JX pump flows 1.4gpm with relief setting of 1400 and 1530psi. The HBC-JY which was used on the SD trucks with hydroboost flows 1.5gpm with a 1450 and 1530psi relief.

So the 6.0 pump put out a nice bump in both flow rate and pressure.

The pump bracket is from an Ebay auto salvage seller. New brackets are also available if you want to spend the money. This is a direct bolt in for the stock OBS part. Your AC compressor and vacuum pump will bolt right up. The orientation of the vacuum pump is now horizontal instead of being tilted up slightly but its actual position on the engine is the same. Same goes for the pump itself which means you do not need to get a longer/shorter belt.

Now for the pulley, this might be the hardest part to get hold of. You need to use the van pulley, no way around this that I'm aware of. The C3 pump shaft is slightly smaller than the C2 so your stock pulley will not fit. The van one is identical to the stock pulley except for the smaller bore. Aftermarket pulleys are not available for the van so get scrounging in the salvage yards. Ebay again came to my rescue with a NOS pulley which is pictured on the left here.

Install is straight forward, just swap one bracket assembly for the other.

The hoses are pretty straight forward too. I used a good quality 3/8 power steering hose to go between the reservoir and hydroboost unit as well as the return line coming off my fluid cooler.

The pressure hose I modified from the stock hydroboost line. I cut off the metal line right where it turns to rubber on the booster end, flared it and used a 3/8 jic coupler. The pump takes a metric ORB fitting, M16 x 1.5 to 3/8 jic. At the time I could not find a supplier who had a 90° fitting in stock so I used a straight one. Thought I could use a hydraulic hose with a 90° elbow on one end but the steering gear lines were in the way. So I used a piece of heavy wall tubing and bent it into a U then bent one leg over at 90° and angled it to line up with the hydraulic hose that connects up to the piece coming off the booster. In the future I plan to neaten this up now that I have a 90° metric to jic fitting. I can dispense with the lower section of bent tubing and just get a longer hydraulic hose.

After double checking everything I filled the system with LE 7500 power fluid and purged the air per Ford's procedure. Now I never really had any issues with my HBC-JY pump which I installed at the same time as my hydroboost unit. However I can say there is a marked improvement with both steering and braking with this new pump! It take less braking effort to stop the truck and steering feels lighter and more positive than before esp at idle and low speeds. No issues noted at all when using brakes and steering at the same time. I do have a spare hydrobooster unit here and am thinking about consulting with VANCO to see if having it ported will yield even better results.