You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Motor Rebuild Help

- Thread starter juniort444e

- Start date

Dmstrucks02

New member

I know what you mean about the money and time issues, but atleast you'll have forged rod motor. Are you going to look into head studs atleast with the boost you will be making?

Fl Stroker

New member

- Joined

- May 18, 2011

- Messages

- 103

- Reaction score

- 0

Be careful unleashing all the power as stock head gaskets even with studs will let go with that much fuel and air. Seasoned gaskets are a different story. Best of luck.

juniort444e

New member

Ok, tore the heads off today to see what im working with. Noticed the cylinder walls still have cross hatching on them. The one cylinder that had 200ish had a weird rusty type stain on the walls, and alot more crusty build up on the cylinder top then the rest. And that same piston, the gasket was destroyed, ripped, what ever you want to call it. What would cause that. I'll post pics up this week sometime. Now back to school, yay.

juniort444e

New member

Sorry about not posting pics. Been crazy busy with nothing.

Quick question to those who have experience, how do i properly measure the bore. I would like to scoop up these pistons but have no idea what sizes are what. Or should i leave this to the machine shop.

Plus this is my finals week so everything is getting torn down once i get home this weekend, as i will have lots of time to do so. And what or how do you guys prep the motor and heads for paint. Do you pressure wash it with something special, or just give it a scrub down with dish soap.

Quick question to those who have experience, how do i properly measure the bore. I would like to scoop up these pistons but have no idea what sizes are what. Or should i leave this to the machine shop.

Plus this is my finals week so everything is getting torn down once i get home this weekend, as i will have lots of time to do so. And what or how do you guys prep the motor and heads for paint. Do you pressure wash it with something special, or just give it a scrub down with dish soap.

juniort444e

New member

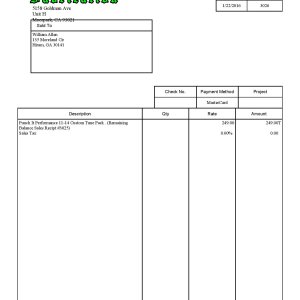

Here are some of the motor.

You can see the close ups of the one cylinder, the walls look rusty, but were smooth. It looked more like a stain. And that is the cylinder that i was told had very low compression. It also had very bad damage to the gasket, where the pushrods come through. Have no idea why. But you can see that in the one pic as well.

You can see the close ups of the one cylinder, the walls look rusty, but were smooth. It looked more like a stain. And that is the cylinder that i was told had very low compression. It also had very bad damage to the gasket, where the pushrods come through. Have no idea why. But you can see that in the one pic as well.

Attachments

SkySki Jason

New member

And what or how do you guys prep the motor and heads for paint. Do you pressure wash it with something special, or just give it a scrub down with dish soap.

If it's really nasty, I'll use diesel and a brush to clean the deepest stuff - but a 0* tip on p-washer will clean about anything. Purple-power to degrease and a final wipe-down with solvent (MEK, lacquer thinner, etc) after the water dries.

The 500* 'engine paint' is fine for everything but the exhaust side of the heads - that needs the VHT 2000* stuff (or Turbo-X).

Also, you might consider ceramic-coating the exhaust manifolds, up-pipes and turbo exhaust housing with Turbo-X (only blue or black):

http://www.techlinecoatingswebstore.com/Exhaust_Coatings-Exhaust_Coating_Turbo_X_Blue_1.html

Here's how my junk turned out:

Turns out 'polishing' the spider, etc was a bad idea. Once the coating, anodizing, whatever is on there from factory is removed - the aluminum will corrode... Either clean and shine without abrasives, or paint these parts. :thumbup:

juniort444e

New member

Thanks for that. Really helps alot.

The uppipes and turbo exhaust housing are already ceramic coated. I do plan on something for the manifolds. Thanks a bunch jason.

The uppipes and turbo exhaust housing are already ceramic coated. I do plan on something for the manifolds. Thanks a bunch jason.

juniort444e

New member

And some of those parts, i will try and have my buddy powder coat some of the parts. Dumb question but can aluminum be powder coated? If so im in business, but either way i need to clean this motor really bad. Sucks to work on dirty stuff.

Mike's Diesel Performance

New member

The best way to measure the bore of the cylinder is with a dial bore gauge but they ae spendy. You could just pic up a snap gauge for the size of the bore and then mic the snap gauge.

juniort444e

New member

Hahaha now your talking words that im still learning about here. :doh:

I'll look into it tho. My dad has some kind on gauge or tool to measure bullets thats pretty accurate. Kind of like this pic. Will that work. And will the measurement differ in different spots on the wall, or can i get an accurate number from the top.

I'll look into it tho. My dad has some kind on gauge or tool to measure bullets thats pretty accurate. Kind of like this pic. Will that work. And will the measurement differ in different spots on the wall, or can i get an accurate number from the top.

Attachments

Mike's Diesel Performance

New member

The measurment will vary. Watch this video, it will give you some pointers

http://youtu.be/Dle58agp4ck

http://youtu.be/Dle58agp4ck

Big Bore

Active member

I didnt read back through the thread to see what all you've had done and couldnt remember but here's some info.

If the bores have not been machined, then your measurements will be useless, and the dial caliper wont measure down inside the bore. After the bores have been cleaned up the machine shop will tell you what size they are.

If the bores have not been machined, then your measurements will be useless, and the dial caliper wont measure down inside the bore. After the bores have been cleaned up the machine shop will tell you what size they are.

juniort444e

New member

I figured one way or another i was going to have an expert measure it anyway. I was just wondering if i could do it myself, so i could pick up some pistons from a member for a good deal. Guess i will have to wait and let the experts do that once i figure out where the motor is going.

Tree Trimmer

New member

- Joined

- May 22, 2011

- Messages

- 2,016

- Reaction score

- 0

as for cleaning, if your taking it to a machine shop, just have them put it in the cleaner. they should have some sort of a steam or solvent cleaner. my guy has both.

they come back virtually ready for paint. just take the rest of the stuff you want painted as well, and just have him add them to the stuff he is already goin to do.

they come back virtually ready for paint. just take the rest of the stuff you want painted as well, and just have him add them to the stuff he is already goin to do.

juniort444e

New member

True, never even thought about that.

PowerstrokeJunkie

Active member

Oh man.. deja vu. Three years ago I tried doing what you're doing now and looking back I wish I took my truck to someone who knew what they were doing :doh:

juniort444e

New member

What did you wish different. Im all ears.

PowerstrokeJunkie

Active member

..Attempting to do something so in-depth and technically skilled while having absolutely no real-world learning or previous experiences doing it. I am not ****ting you if i had put the setup in my truck im running right now back in 2008 i would have saved over 25,000 dollars. you're not going that extreme, however you WILL mess something up along the way simply due to the fact you don't know what you're doing. I did several times :shrug:

juniort444e

New member

Thats understandable.

We will see what happens in Jan and Feb though. Thats when I will have the money and this will start and hopefully finish as well.

Truck will start to get torn down tomorrow, even though its snowing. And getting everything preped to clean and fix all the little issues.

We will see what happens in Jan and Feb though. Thats when I will have the money and this will start and hopefully finish as well.

Truck will start to get torn down tomorrow, even though its snowing. And getting everything preped to clean and fix all the little issues.