You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My tow pig/DD build thread. F350/Cummins 6.7/twins/6R140

- Thread starter me2

- Start date

Vader's Fury

Active member

pm sent

There is always a lot of prep work to do on a new (to me, anyway) truck.

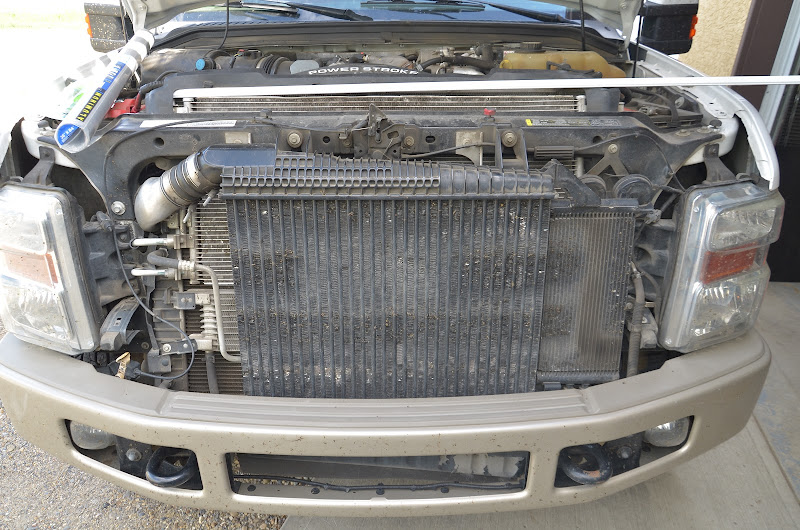

Not really swap related, but here is my poor man's bug screen as I hate having stuff plugging the fins on the various coolers.

The white piece is screen door frame. I got everything from Lowes for $20. Be sure to use real aluminum screen, not the plastic stuff.

I'll complete the bottom after the swap is done in case there are changes to the coolers that would affect the length.

I love it that the grill opens with the hood on my truck, giving me full access to the rad/intercooler. I was envious of that on the Dodge trucks back when they had it.

The screen can be removed and cleaned with a simple garden hose and replaced in 10 minutes. Sure beats trying to flush bug parts from the rad fins.

My intercooler is in better condition than the pictures would have you believe. However, I still need to spend a bit of time on it with a fin comb.

I like a rad/intercooler screen better than the grill plug ins because they don't restrict the air flow as much.

With the hood down you can't see the screen, except for the cut out in the bumper. It would be less obvious if I framed the bottom edge and ended it in line with the bottom of the intercooler.

I ran a similar screen setup on my old truck.

FWIW, I'm running General Grabber tires (275/65R20) on the front axle. Obviously I don't do a lot of off roading.

http://www.tirerack.com/tires/tires...GRHTSOWL&vehicleSearch=false&fromCompare1=yes

I've got over 20K on them and they are doing great.

One thing I really like about the Grabbers is that they are way less prone to hydroplane than the usual Goodyear Wranglers. Nothing worse than running a rutted 2 lane highway on a pitch black night in hard rain and feeling the front end moving around with every puddle while meeting oncoming semis pulling B trains. I think Wranglers are really bad for hydroplaning, especially when they are worn down.

Not really swap related, but here is my poor man's bug screen as I hate having stuff plugging the fins on the various coolers.

The white piece is screen door frame. I got everything from Lowes for $20. Be sure to use real aluminum screen, not the plastic stuff.

I'll complete the bottom after the swap is done in case there are changes to the coolers that would affect the length.

I love it that the grill opens with the hood on my truck, giving me full access to the rad/intercooler. I was envious of that on the Dodge trucks back when they had it.

The screen can be removed and cleaned with a simple garden hose and replaced in 10 minutes. Sure beats trying to flush bug parts from the rad fins.

My intercooler is in better condition than the pictures would have you believe. However, I still need to spend a bit of time on it with a fin comb.

I like a rad/intercooler screen better than the grill plug ins because they don't restrict the air flow as much.

With the hood down you can't see the screen, except for the cut out in the bumper. It would be less obvious if I framed the bottom edge and ended it in line with the bottom of the intercooler.

I ran a similar screen setup on my old truck.

FWIW, I'm running General Grabber tires (275/65R20) on the front axle. Obviously I don't do a lot of off roading.

http://www.tirerack.com/tires/tires...GRHTSOWL&vehicleSearch=false&fromCompare1=yes

I've got over 20K on them and they are doing great.

One thing I really like about the Grabbers is that they are way less prone to hydroplane than the usual Goodyear Wranglers. Nothing worse than running a rutted 2 lane highway on a pitch black night in hard rain and feeling the front end moving around with every puddle while meeting oncoming semis pulling B trains. I think Wranglers are really bad for hydroplaning, especially when they are worn down.

Last edited:

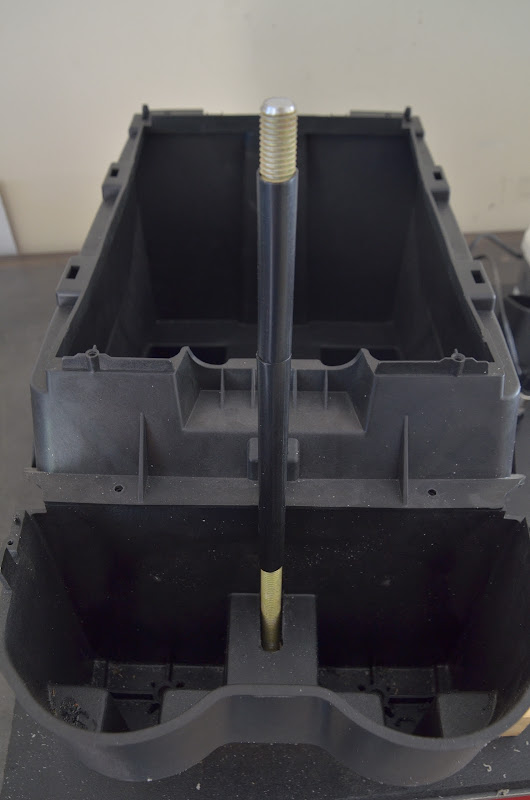

I am trying to get the console shifter and AC outlets done before the weekend so that I don't have to take the console out again to finish the job.

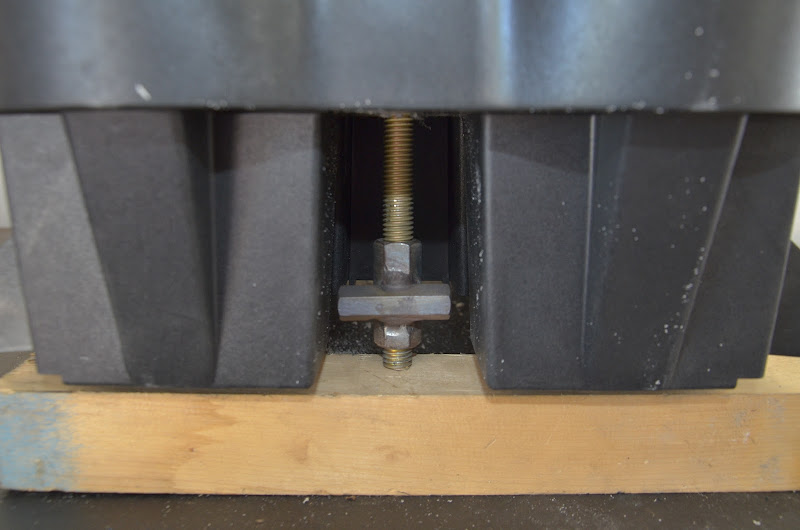

The shifter is done except for the return springs, lever pivot and switch mounting and some adjustment.

I'll get a (matching leather) skirt sewn up to cover the wires under the knob. Anyone know where to find leather to match the King Ranch leather ?

The plastic covering on the threaded rod is double wall heat shrink, unshrunk at this point.

I like how it turned out so far, but I'm worried about the return springs.

I think the position and travel is perfect for bump style shifting that I intend to do. I could get more travel by moving the pivot upwards and I just might do that.

The cup clearance is good though you have to reach around the shift lever to get to the passenger cup from the driver's seat.

This is a 2 position momentary contact system. Forward = up, backwards = down. Spring return to center. There is enough room to make it a 4 position system, adding a position on each side of center. I'm not sure exactly what I would use them for. I'll try a 2 position system first and see how I like it.

Back to work on the trailer. Uggghhh.

The shifter is done except for the return springs, lever pivot and switch mounting and some adjustment.

I'll get a (matching leather) skirt sewn up to cover the wires under the knob. Anyone know where to find leather to match the King Ranch leather ?

The plastic covering on the threaded rod is double wall heat shrink, unshrunk at this point.

I like how it turned out so far, but I'm worried about the return springs.

I think the position and travel is perfect for bump style shifting that I intend to do. I could get more travel by moving the pivot upwards and I just might do that.

The cup clearance is good though you have to reach around the shift lever to get to the passenger cup from the driver's seat.

This is a 2 position momentary contact system. Forward = up, backwards = down. Spring return to center. There is enough room to make it a 4 position system, adding a position on each side of center. I'm not sure exactly what I would use them for. I'll try a 2 position system first and see how I like it.

Back to work on the trailer. Uggghhh.

Last edited:

brewer

Member

- Joined

- May 18, 2011

- Messages

- 191

- Reaction score

- 0

Look up "Texas Fabric and Foam" in El Paso. When I looked awhile ago, I had heard they had rolls of the material, but never looked into it further.Anyone know where to find leather to match the King Ranch leather ?

Otherwise, it's just saddle leather, so either an upholstery shop or a saddle & tack shop should be able to get you some saddle leather. Then even if it's slightly off you could oil it (neatsfoot oil, mink oil, etc.) to adjust the color to match; those will darken the leather. I've even heard olive oil works, but I would rather not try it LOL.

I got bad news on my flexplate plan today.

Turns out the hardest part of this project is connecting the 6R140 torque converter to the Cummins 6.7 crankshaft.

I have a few more paths to check out though. I'll look into it further next week.

Turns out the hardest part of this project is connecting the 6R140 torque converter to the Cummins 6.7 crankshaft.

I have a few more paths to check out though. I'll look into it further next week.

Project20v

New member

Here is 2 pictures of the external ac plug in the back of my tacoma I use for work. It is mounted into the plastic bed liner

I just bought 3 of these. They're just right for what I need. Thanks for the lead..

Miscellaneous Blatherings

Big Single Turbos

Here is why I am not going with a big single turbo on this project.

http://www.competitiondiesel.com/forums/showthread.php?t=136402

Its a 5.9, but the turbo is "only" an S472, so that is probably similar to running an S475 on a 6.7.

Air Ride Suspension

So my 08 F350 has been hooked to our 5th wheel trailer this week and thus I'm driving my '99 F250 (5.9CR, ZF6). It has rear air ride suspension, as built in this thread.

http://powerstrokenation.com/forums/showthread.php?t=43770

It also had front air ride suspension, but I removed it due to damage when it was stolen.

Long story short, I can't believe how terrible the 08 rides compared to the '99. Especially when towing the trailer. The 08 is getting air ride as soon as the swap is done.

I've started a thread for it here.

http://powerstrokenation.com/forums/showthread.php?t=117771

5th Wheel Hitches

And while I'm working on suspension stuff this fall, I'm going to build an air ride 5th wheel hitch with a cushioned pin. I've had enough of having a rough ride when towing a 5er on rough roads.

For various reasons I am not going to install the TrailAir Triglide pinbox I bought for our 5er.

Big Single Turbos

Here is why I am not going with a big single turbo on this project.

http://www.competitiondiesel.com/forums/showthread.php?t=136402

Its a 5.9, but the turbo is "only" an S472, so that is probably similar to running an S475 on a 6.7.

Air Ride Suspension

So my 08 F350 has been hooked to our 5th wheel trailer this week and thus I'm driving my '99 F250 (5.9CR, ZF6). It has rear air ride suspension, as built in this thread.

http://powerstrokenation.com/forums/showthread.php?t=43770

It also had front air ride suspension, but I removed it due to damage when it was stolen.

Long story short, I can't believe how terrible the 08 rides compared to the '99. Especially when towing the trailer. The 08 is getting air ride as soon as the swap is done.

I've started a thread for it here.

http://powerstrokenation.com/forums/showthread.php?t=117771

5th Wheel Hitches

And while I'm working on suspension stuff this fall, I'm going to build an air ride 5th wheel hitch with a cushioned pin. I've had enough of having a rough ride when towing a 5er on rough roads.

For various reasons I am not going to install the TrailAir Triglide pinbox I bought for our 5er.

SEABEE08FX4

New member

Unless you just must have a turbo brake I'd ditch the whole VGT turbo all together. We have done a few 6.7 turbo swaps and those things spool up a 66 like nothing. Zero lag at all, from there you could just add a inline or downpipe exhaust brake and it would probably make fitment easier on you.

Cool project though.

Cool project though.

Strokersace

Well-known member

Good luck on the flexplate deal. I wanna see this materialize smoothly.

Me too ! LOLI wanna see this materialize smoothly.

bad12jr

New member

- Joined

- May 25, 2011

- Messages

- 1,244

- Reaction score

- 0

Not tired yet. Lots of good info in this one and its really helping me decide what gas truck to buy for a swap.

Sent from my x2 somewhere

Sent from my x2 somewhere

I've (finally) come up with a solution for the flex plate and transmission adapter parts.

I'm thinking that I'll mount the Ford flex plate to the Cummins crankshaft by water jet cutting the center of the Ford flex plate out and attaching it to an adapter plate with the Cummins crank pattern via special bolts.

I'm retaining the Ford flex plate because

- it fits in the 6R140 bellhousing using the Cummins starter

- it is tightly/nicely contoured to the 6R140 torque converter

- it will still allow some axial flexing as a flex plate should

- it appears decently beefy enough, especially with the center replaced by the adapter plate

I do not have to cut any new holes in the Ford flex plate to mount the adapter plate to it. It mounts via pre existing holes.

The transmission adapter plate will be fashioned from 3 mild steel pieces, which will be pinned and welded together. I'll price getting them made in aluminum just for the fun of it, but I'm pretty sure I'll be making them from steel. It won't be very heavy even in steel.

One nice thing about the adapter plate design is that its quite shallow.

The Cummins 5.9 and 6.7 engines are a bit longer than the Ford V8 diesels. The general protocol for getting a 5.9/6.7 into a Superduty is to get the Cummins fan as tight up to the rad as you dare (or replace it with an electric fan) and then deal with however far back the transmission gets pushed. Anything that minimizes how much the transmission gets pushed back is a bonus.

My transmission adapter will be 1.5 inches thick from the Cummins block to the 6R140 face. The stock 68RFE plate is about an inch thicker than that and the standard Cummins ISB SAE2 adapter is over 5 inches thick.

The later would require a 3.5+ inch spacer between the 6.7 crank and the Ford flex plate to get the spacing correct and would most certainly move the transmission back on the truck quite a bit, possibly causing the case to rub on the transmission tunnel.

I was hoping to keep the transmission adapter plate thickness down to 1/2" or so, but the 6.7 crankshaft sticks out too far from the block and the 6R140 torque converter is too long to achieve that.

The 1.5" adapter plate thickness puts the flexplate and the 6R140 TC in the same position vis a vis the transmission face as it is stock with a Ford 6.7.

There are a ton of geometry constraints to make everything fit and work, but I think I've come up with something that does.

I'll sleep on the design and if I still like it tomorrow, I'll remeasure and double check everything and then send the parts off for cutting.

This was my first time adapting an automatic transmission to a different engine. Its much more complicated adapting a flex plate and torque converter to an engine than it is a clutch.

With a clutch you generally find a clutch plate that works with a pressure plate that can be bolted to to the engine's existing flywheel and then lay out the adapter plate to fit.

With a flexplate, you either have to machine one that works from scratch or figure out how to adapt an off the shelf flex plate to the engine crank. With the 6.7 flex plate, I had very few off the shelf items to select from because I did not find any aftermarket 6.7 flex plates and none of the Cummins flex plates would allow me to keep the 6.7 starter placement. Thus the only flex plate I had to work with was the Ford 6.7 flex plate.

As my mom would say, it was a character building experience. :doh:

I'm thinking that I'll mount the Ford flex plate to the Cummins crankshaft by water jet cutting the center of the Ford flex plate out and attaching it to an adapter plate with the Cummins crank pattern via special bolts.

I'm retaining the Ford flex plate because

- it fits in the 6R140 bellhousing using the Cummins starter

- it is tightly/nicely contoured to the 6R140 torque converter

- it will still allow some axial flexing as a flex plate should

- it appears decently beefy enough, especially with the center replaced by the adapter plate

I do not have to cut any new holes in the Ford flex plate to mount the adapter plate to it. It mounts via pre existing holes.

The transmission adapter plate will be fashioned from 3 mild steel pieces, which will be pinned and welded together. I'll price getting them made in aluminum just for the fun of it, but I'm pretty sure I'll be making them from steel. It won't be very heavy even in steel.

One nice thing about the adapter plate design is that its quite shallow.

The Cummins 5.9 and 6.7 engines are a bit longer than the Ford V8 diesels. The general protocol for getting a 5.9/6.7 into a Superduty is to get the Cummins fan as tight up to the rad as you dare (or replace it with an electric fan) and then deal with however far back the transmission gets pushed. Anything that minimizes how much the transmission gets pushed back is a bonus.

My transmission adapter will be 1.5 inches thick from the Cummins block to the 6R140 face. The stock 68RFE plate is about an inch thicker than that and the standard Cummins ISB SAE2 adapter is over 5 inches thick.

The later would require a 3.5+ inch spacer between the 6.7 crank and the Ford flex plate to get the spacing correct and would most certainly move the transmission back on the truck quite a bit, possibly causing the case to rub on the transmission tunnel.

I was hoping to keep the transmission adapter plate thickness down to 1/2" or so, but the 6.7 crankshaft sticks out too far from the block and the 6R140 torque converter is too long to achieve that.

The 1.5" adapter plate thickness puts the flexplate and the 6R140 TC in the same position vis a vis the transmission face as it is stock with a Ford 6.7.

There are a ton of geometry constraints to make everything fit and work, but I think I've come up with something that does.

I'll sleep on the design and if I still like it tomorrow, I'll remeasure and double check everything and then send the parts off for cutting.

This was my first time adapting an automatic transmission to a different engine. Its much more complicated adapting a flex plate and torque converter to an engine than it is a clutch.

With a clutch you generally find a clutch plate that works with a pressure plate that can be bolted to to the engine's existing flywheel and then lay out the adapter plate to fit.

With a flexplate, you either have to machine one that works from scratch or figure out how to adapt an off the shelf flex plate to the engine crank. With the 6.7 flex plate, I had very few off the shelf items to select from because I did not find any aftermarket 6.7 flex plates and none of the Cummins flex plates would allow me to keep the 6.7 starter placement. Thus the only flex plate I had to work with was the Ford 6.7 flex plate.

As my mom would say, it was a character building experience. :doh:

Hotrodtractor

Moderator

Make sure you match balance the Ford flexplate to the correct flexplate for the Cummins.

I'll blather about my truck's shortcomings and other thoughts when I take a break from working on things.Not tired yet. Lots of good info in this one and its really helping me decide what gas truck to buy for a swap.

Right now I want to stay focused on doing the swap rather than posting. Though I will post things as I do things.

Though on that train of thought, sometimes there is a lot going on in the background that doesn't warrant posting about. Like taking a zillion engine/flex plate/torque converter/transmission measurements and trying about 34 different combinations of parts, for example. You guys would question my intelligence if I had posted everything I thought about solving that little problem.

Having said all that, on the topic of trucks, I still love my 08 F350. I don't think its any worse than any other tow pig candidate and its probably better in many respects. And it doesn't have any shortcomings that can't be corrected with some work.

Make sure you match balance the Ford flexplate to the correct flexplate for the Cummins.

Please tell me how to do that !

I forgot to post above that the flex plate balance is still one of the things I am trying to figure out.

The Ford flex plate is keyed to the Ford crankshaft and it has big balance weights hanging on it. People tell me the 6.7 is probably externally balanced by the flexplate.

Dodge/Cummins flex plates are NOT keyed to the crank but do have balance holes drilled in them. What is up with that ? Are they just balanced unto themselves or is something else going on ?

I spoke with an engine builder this morning that told me a) they could balance the flex plate by itself and b) it should really be done together with the crank, rods and pistons ! But the same guy told me that I should replace my 6.7 crankshaft with a 5.9 crankshaft because the 5.9 cranks are stronger. He didn't realize that the 6.7 has a longer stroke. So I don't know what to believe.

One more thing. I'll be making up 2 flex plate/adapter assemblies and carrying one along on the truck at all times so that if I break one on a long trip, I have a spare ready to swap in to get me home. Nothing worse than having a custom made part fail and not having a backup available. FYI, a Ford 6.7 flex plate is about $80 IIRC.

One more little tidbit. A little birdie (not Mark K) told me that it would not be possible to weld the Ford flex plate without it cracking down the road, more so than a "normal" flex plate would, due to the heat treatment and metalurgy it has. Whereas some other flex plates can be welded, the 6R140 flex plate should not be.

I know that the starter ring gear is welded to the 6R140 FP as are the balance weights. That is different from welding in a new center, for example.

I've got a ton of other things to blather about from stuff I learned recently, but I want to focus on my swap right now.

Last edited:

One other thing. My (current) transmission adapter design puts the starter on the passenger side, as it is on a 2011+ Superduty.

This creates problems for the rear turbocharger placement, but prevents me from having to modify the 6R140 transmission case. However, I'm about this close (peeping through closed fingers) to moving it back to the driver's side.

Like I said, I need to sleep on things.

This creates problems for the rear turbocharger placement, but prevents me from having to modify the 6R140 transmission case. However, I'm about this close (peeping through closed fingers) to moving it back to the driver's side.

Like I said, I need to sleep on things.