You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CNC Ported Scorpion Heads

- Thread starter R&D Injection

- Start date

So since head porting was mention in this thread, let's talk about that.... Being that intake runners themselves are basic impossible to get to, what does a basic 6.7 port job consist of? Pocket porting, new valve job, and of course the exhaust runners? And then there's the valve covers/intake manifolds.... And I mentioned the valve job as often times a good bit more flow can be found with good valve job. Has anyone gone to larger seats with larger valves? The idea is to increase the CFM while retaining as much velocity as possible....If done correctly the same amount of power can be obtained with less boost pressure as all the boost pressure really is is a measurement of resistance, right???

So if we can discuss this without all the bull**** arguing, that would be nice!!!!

So if we can discuss this without all the bull**** arguing, that would be nice!!!!

CATDiezel

New member

- Joined

- Dec 27, 2011

- Messages

- 2,221

- Reaction score

- 0

So since head porting was mention in this thread, let's talk about that.... Being that intake runners themselves are basic impossible to get to, what does a basic 6.7 port job consist of? Pocket porting, new valve job, and of course the exhaust runners? And then there's the valve covers/intake manifolds.... And I mentioned the valve job as often times a good bit more flow can be found with good valve job. Has anyone gone to larger seats with larger valves? The idea is to increase the CFM while retaining as much velocity as possible....If done correctly the same amount of power can be obtained with less boost pressure as all the boost pressure really is is a measurement of resistance, right???

So if we can discuss this without all the bull**** arguing, that would be nice!!!!

Measure of resistance yes. But where. Who knows. It could be what's called "line pack" or simply flow resistance.

The best netted results would be from bigger valves/longer duration (cam). Or effectively getting the line pack to the valve itself.

Wow.... what a thread. Have no idea who the fella is, but it appears he was just trying to judge interest and even complied nicely with Mikey. With that said Mikey was nice about it as well.... it certainly dies not pose a "threat" to anyone.

A little pricey, sure... but we're talking about a group of guys that will drop $8k on a lift/wheels/tires... so....??

R&D Injection

New member

- Joined

- Feb 19, 2015

- Messages

- 15

- Reaction score

- 0

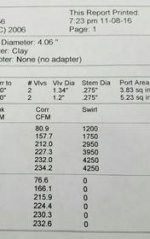

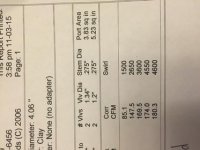

Over 3,000 views since my last login. Hmm, I really stirred something up here I guess. I'm not a vendor here so I'm not going to try to sell anything. I am going to respond to some comments of people that have good questions. The big shop nut swingers or anyone who has negative comments, please start your own thread. There are places for people to learn, and I would like this thread to answer some people's questions. We've done extensive development over three course of a year on the heads. Mainly because I like the platform and see its potential. Our goal unlike many other shops out there is to maintain a small port, keep airspeed and swirl up, and while doing this, increase cfm across the whole valve lift curve. When you maintain port size and increase cfm, your gains are always only postive gains. I'm not going to get into all the details until I do right by this forum and pay for my place like everyone else. I will post a couple flow charts so all your naysayers can see for yourself.

Here are the basics.

Stock heads flow 180intake and 160cfm exhaust stock size valves. We've touched up the intake bowls and developed a very different shape on the exhaust port. The exhaust port flows very well and from our numerous designs, we decided to enlarge the exhaust port slightly while maintaining near stock cc intake bowls. Our gains for the small amount of work we've done to these, have been very impressive. I will post stock flow and then a sheet with intake and exhaust flow after porting. These aren't your backyard hand ported heads like some are speaking of. These were developed over the course of a years worth of development and we are happy to have something for people to have for bolt on power, torque, spool, and most of all, a broader effiecient power curve. I will bring some solid numbers for those interested at the beginning of the year when we've paid for our place on this forum.

Here are the basics.

Stock heads flow 180intake and 160cfm exhaust stock size valves. We've touched up the intake bowls and developed a very different shape on the exhaust port. The exhaust port flows very well and from our numerous designs, we decided to enlarge the exhaust port slightly while maintaining near stock cc intake bowls. Our gains for the small amount of work we've done to these, have been very impressive. I will post stock flow and then a sheet with intake and exhaust flow after porting. These aren't your backyard hand ported heads like some are speaking of. These were developed over the course of a years worth of development and we are happy to have something for people to have for bolt on power, torque, spool, and most of all, a broader effiecient power curve. I will bring some solid numbers for those interested at the beginning of the year when we've paid for our place on this forum.

Attachments

R&D Injection

New member

- Joined

- Feb 19, 2015

- Messages

- 15

- Reaction score

- 0

- Joined

- May 22, 2011

- Messages

- 15,240

- Reaction score

- 1

i wanna say my last set , which was already ported to 195-200 , went to another shop ended somewhere around 210 average. it was alot more work on top of a set i had already paid alot to have done. 230+ would be a great improvement IMO . pretty sure i already have $4000 in mine just to have 210 . i'll have to look and see if i have the before and afters still, as that was a year or more ago .

good numbers man .

good numbers man .

R&D Injection

New member

- Joined

- Feb 19, 2015

- Messages

- 15

- Reaction score

- 0

i wanna say my last set , which was already ported to 195-200 , went to another shop ended somewhere around 210 average. it was alot more work on top of a set i had already paid alot to have done. 230+ would be a great improvement IMO . pretty sure i already have $4000 in mine just to have 210 . i'll have to look and see if i have the before and afters still, as that was a year or more ago .

good numbers man .

Ouch!!! Someone's really proud of their work it sounds like. Cnc porting should only cost $1500 a head. At least that's where I'll be at. Parts like high end valves, seats, springs, tubes, steel rockers & rocker bar and other parts are what really adds up fast.

WHY NOT

New member

Ok, for guys that don't quite get the flow numbers, I get bigger is better etc etc more air = more power but how much more power could 50cfm make? Just say on a truck that would benefit it from it say its making 900-1000 hp already then just added your heads.

WhiteMamba_Scorpion

Active member

- Joined

- Jan 10, 2014

- Messages

- 1,952

- Reaction score

- 0

What's the max CFM the valves can efficiently flow until they need work.

- Joined

- May 22, 2011

- Messages

- 15,240

- Reaction score

- 1

Ouch!!! Someone's really proud of their work it sounds like. Cnc porting should only cost $1500 a head. At least that's where I'll be at. Parts like high end valves, seats, springs, tubes, steel rockers & rocker bar and other parts are what really adds up fast.

not sure what you mean about ouch or proud, but when i had my first set done , very few were doing it , i wanna say the first set was done for $2400 . i was given no guarantees. so the next time i had the motor apart i had another shop go thru them and improve and i wanna say they charged me $1500 . as far as i know it's all based on hourly , so they put in the time ,and charge you for it. at least i saw improvement with on a flow bench. just an FYI this isnt my first rodeo , i'm just giving examples of what 6.7 head porting was like back in 2013 .

R&D Injection

New member

- Joined

- Feb 19, 2015

- Messages

- 15

- Reaction score

- 0

not sure what you mean about ouch or proud, but when i had my first set done , very few were doing it , i wanna say the first set was done for $2400 . i was given no guarantees. so the next time i had the motor apart i had another shop go thru them and improve and i wanna say they charged me $1500 . as far as i know it's all based on hourly , so they put in the time ,and charge you for it. at least i saw improvement with on a flow bench. just an FYI this isnt my first rodeo , i'm just giving examples of what 6.7 head porting was like back in 2013 .

I didn't mean anything rude by what I said. But I see these outrageous prices for stuff because it's "diesel". This market is highly overpriced and people really take advantage of people. What you paid for those gains "in my opinion" is very high. those prices are with the shelf on still I'm assuming?

- Joined

- May 22, 2011

- Messages

- 15,240

- Reaction score

- 1

I didn't mean anything rude by what I said. But I see these outrageous prices for stuff because it's "diesel". This market is highly overpriced and people really take advantage of people. What you paid for those gains "in my opinion" is very high. those prices are with the shelf on still I'm assuming?

none of my porting has been by any diesel shop. race car machine shops here in so cal. as for the shelf, no idea .

- Joined

- May 22, 2011

- Messages

- 15,240

- Reaction score

- 1

I think when you put your truck together Mike they probably had never seen a 6.7 cyl head either. You are usually the one paying for r&d.

agreed. and ive had the same shop do a couple other big hp heads , i think we've seen 1180 on fuel with the last set on nick aldarelli's truck, and that was with a boost leak.

i'm all for way better stuff.

R&D Injection

New member

- Joined

- Feb 19, 2015

- Messages

- 15

- Reaction score

- 0

This has went no where because no one wants to spend money on something new....but I'm not surprised by this.

WhiteMamba_Scorpion

Active member

- Joined

- Jan 10, 2014

- Messages

- 1,952

- Reaction score

- 0

Have you put them on any engines of your own to prove they are worth it yet?This has went no where because no one wants to spend money on something new....but I'm not surprised by this.

- Joined

- May 22, 2011

- Messages

- 15,240

- Reaction score

- 1

This has went no where because no one wants to spend money on something new....but I'm not surprised by this.

how come you don't do it yourself on your motor ?

R&D Injection

New member

- Joined

- Feb 19, 2015

- Messages

- 15

- Reaction score

- 0

I have them on my motor obviously but I've had a hard time finding and engine dyno ready for the scorpion. I don't want to spend $1009s more to hook it up on a dyno when I already know what the results are going to be. I've spoke with some of the biggest shops in the country they say they want them but their just talking and I haven't seen anyone put up any money. Typical.. I've offered free heads to dyno back to back and buy after they see the results and still no takers. Just a lot smaller market and not big spenders compared what I'm used to dealing with in the Cummins market is all. No big deal...give it time, it will come around....

WHY NOT

New member

I have them on my motor obviously but I've had a hard time finding and engine dyno ready for the scorpion. I don't want to spend $1009s more to hook it up on a dyno when I already know what the results are going to be. I've spoke with some of the biggest shops in the country they say they want them but their just talking and I haven't seen anyone put up any money. Typical.. I've offered free heads to dyno back to back and buy after they see the results and still no takers. Just a lot smaller market and not big spenders compared what I'm used to dealing with in the Cummins market is all. No big deal...give it time, it will come around....

You may know what the results are going to be, but none of us do, just saying. Stock heads vs these on the same truck same set up same dyno etc etc would go a long way. If you really want to to try talking someone into trying them the guy right above your post would be a good person to go to. He has been in the game a long time, knows his stuff and has a great outlet to sell a product if it works as advertised.